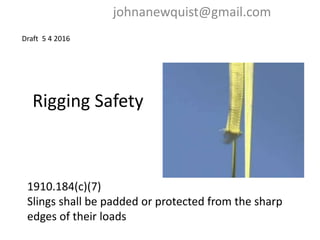

Rigging equipment like slings, chains, and shackles must be inspected daily for damage or defects and removed from service if unsafe. Proper personal protective equipment should be worn when handling loads. Accidents can occur if loads are not properly secured during lifting or if rigging is overloaded or used at angles that reduce its rated capacity. OSHA regulations specify standards for inspection, maintenance, and use of rigging hardware to prevent injuries and fatalities from falling or shifting equipment.

![241

262

279

339

544

176(b)

178(l)(6)

178(p)(1)

178(l)(4)(iii)

178(l)(1)(i)

Materials Handling & Storage

[1910.176 – .184]

6

SUBPARTN

POWERED INDUSTRIAL TRUCKS – COMPETENCY TRAINING

POWERED INDUSTRIAL TRUCKS – REFRESHER TRAINING IN RELEVANT TOPICS

POWERED INDUSTRIAL TRUCKS – CERTIFICATION OF TRAINING

POWERED INDUSTRIAL TRUCKS – SAFE OPERATING CONDITION

MATERIAL HANDLING – STORAGE OF MATERIAL SHALL NOT CREATE A HAZARD](https://image.slidesharecdn.com/gi2016industrialriggingsafety-160505191146/85/Gi-2016-industrial-rigging-safety-6-320.jpg)

![MATERIALS STORED TO PREVENT SLIDING FALLING, OR COLLAPSE

9

9

10

17

18

251(a)(2)(i)

250(a)(1)

251(b)(1)

251(a)(1)

252(a)

Materials Handling, Storage, Use & Disposal

[1926.250 – 252]

7

GENERAL RIGGING EQUIPMENT IDENTIFICATION

EXTERIOR DROP CHUTES

RIGGING EQUIPMENT INSPECTION & REMOVAL FROM SERVICE

WELDED ALLOY STEEL CHAIN SLING IDENTIFICATION

SUBPARTH](https://image.slidesharecdn.com/gi2016industrialriggingsafety-160505191146/85/Gi-2016-industrial-rigging-safety-7-320.jpg)