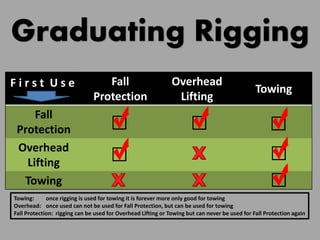

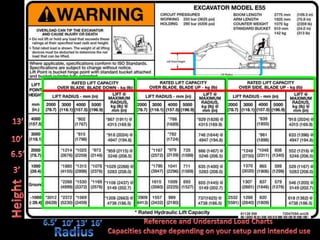

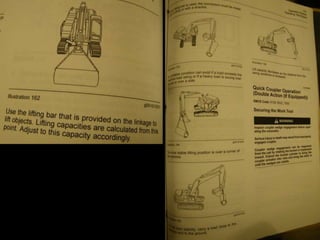

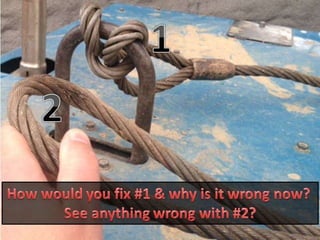

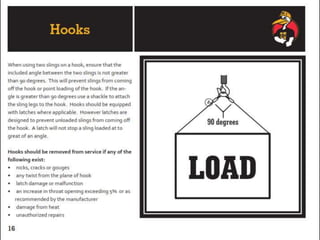

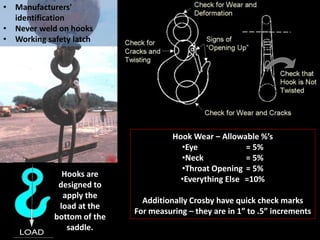

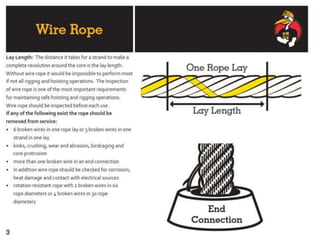

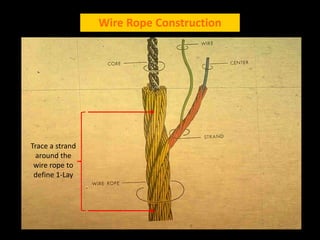

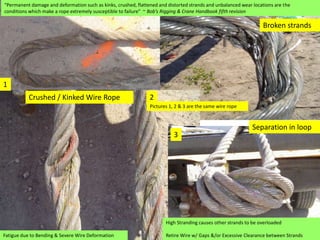

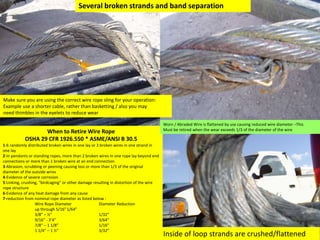

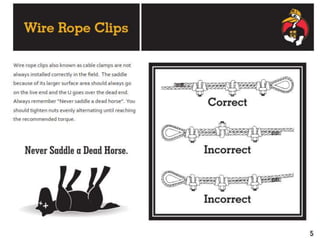

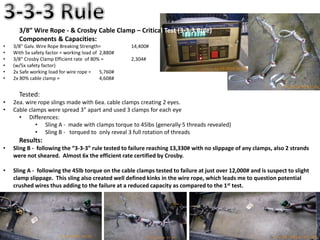

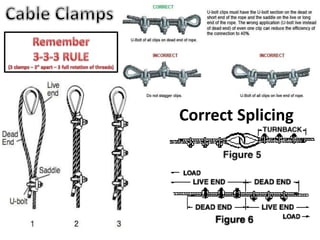

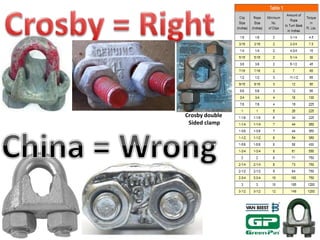

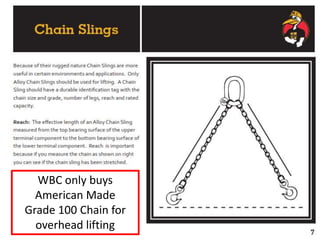

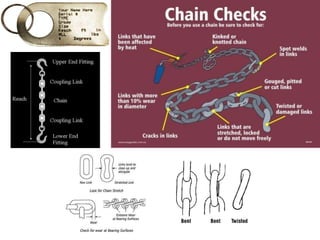

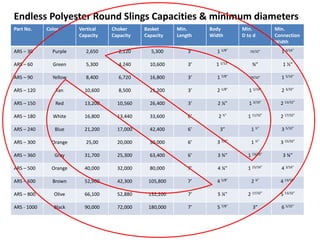

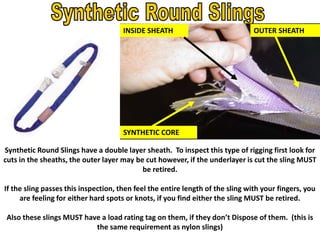

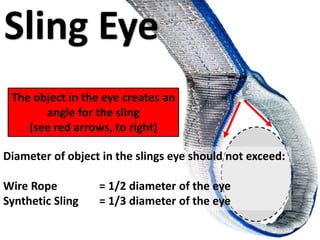

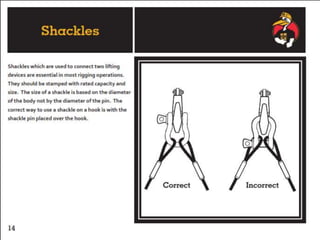

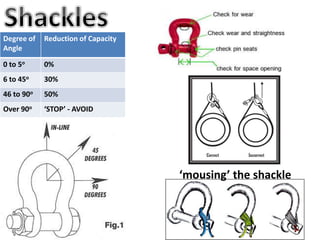

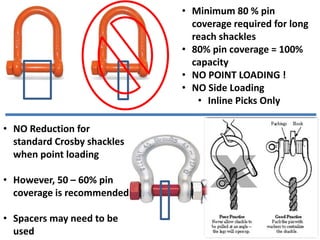

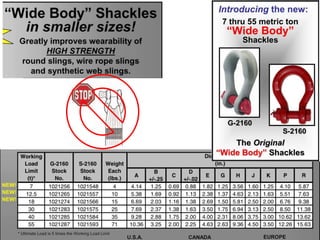

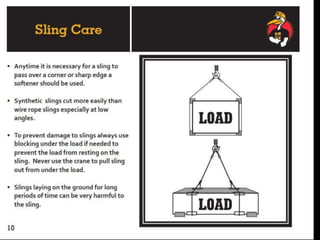

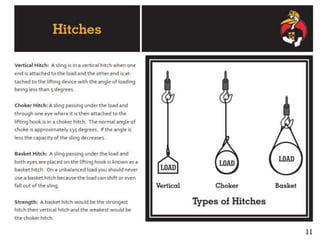

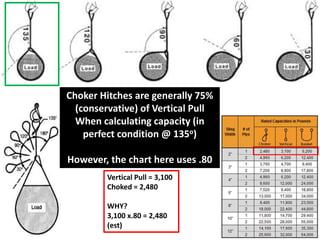

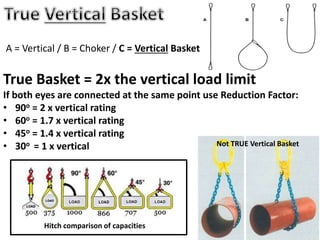

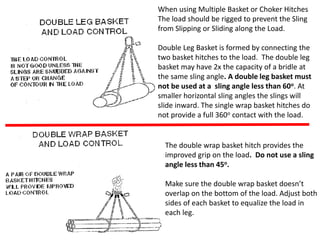

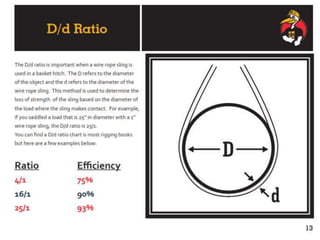

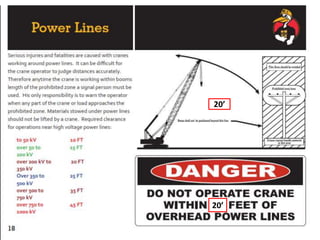

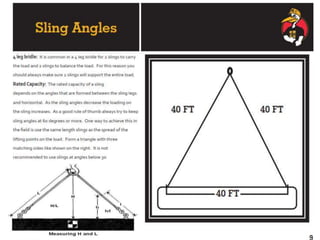

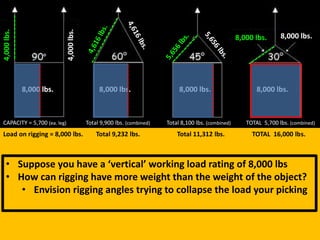

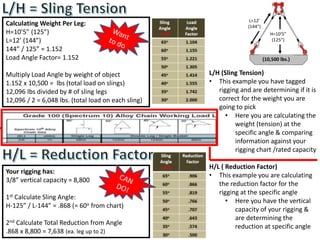

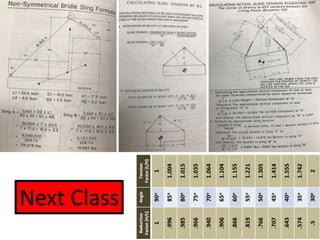

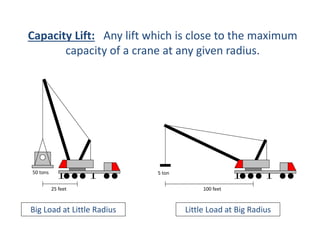

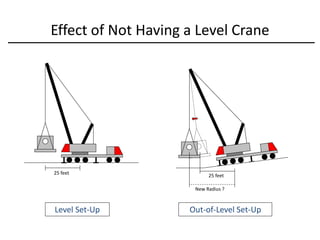

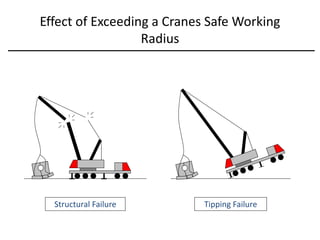

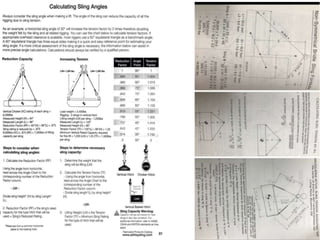

The document discusses various issues with rigging, including that rigging is complicated and breaks for no reason. It also mentions that rigging is worn out and too expensive to replace with hardware store items. The document then provides information on proper rigging use and inspection, including graduation rules for different types of rigging use, manufacturer and wear identification, and inspection criteria. It also covers wire rope construction, types of synthetic round slings, and various rigging configurations and their capacities.