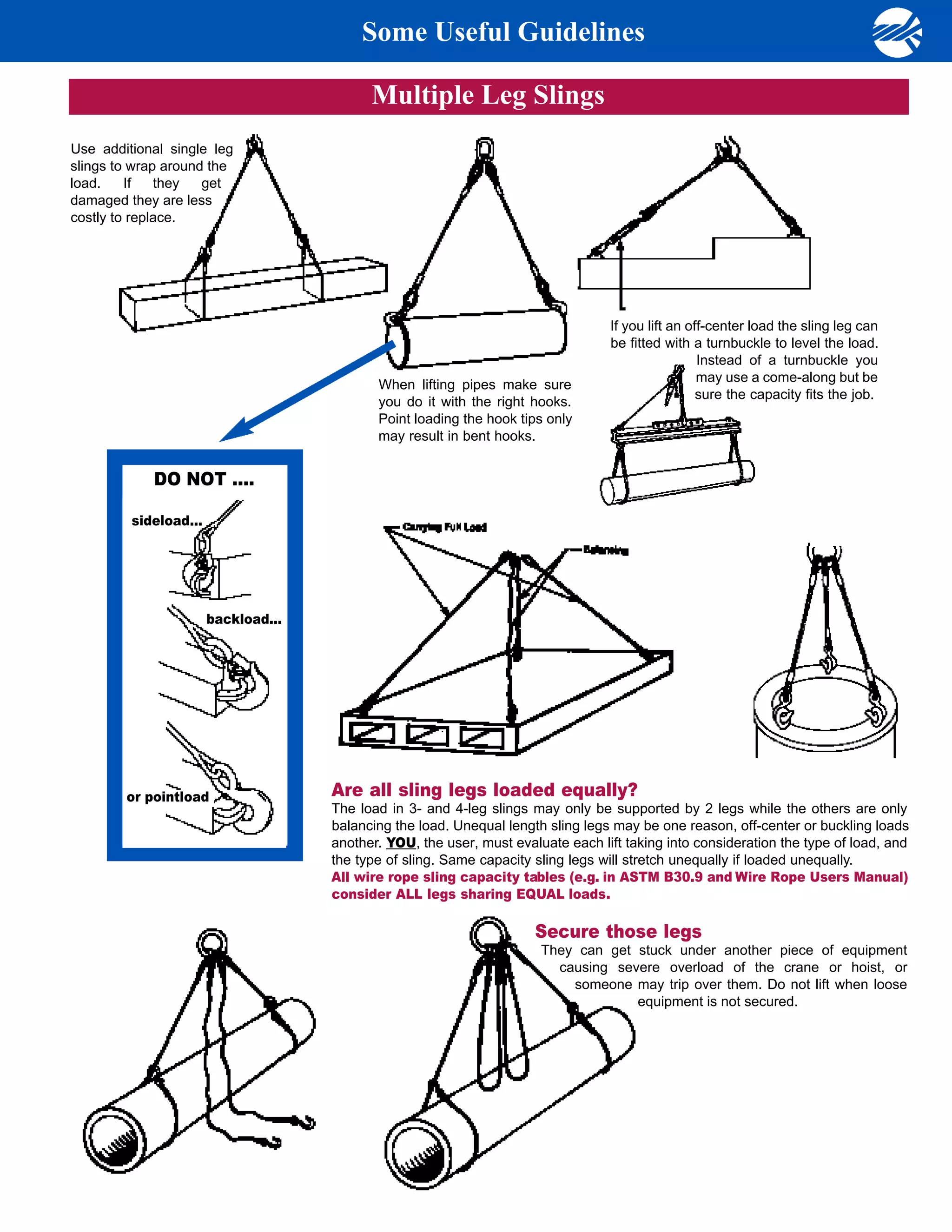

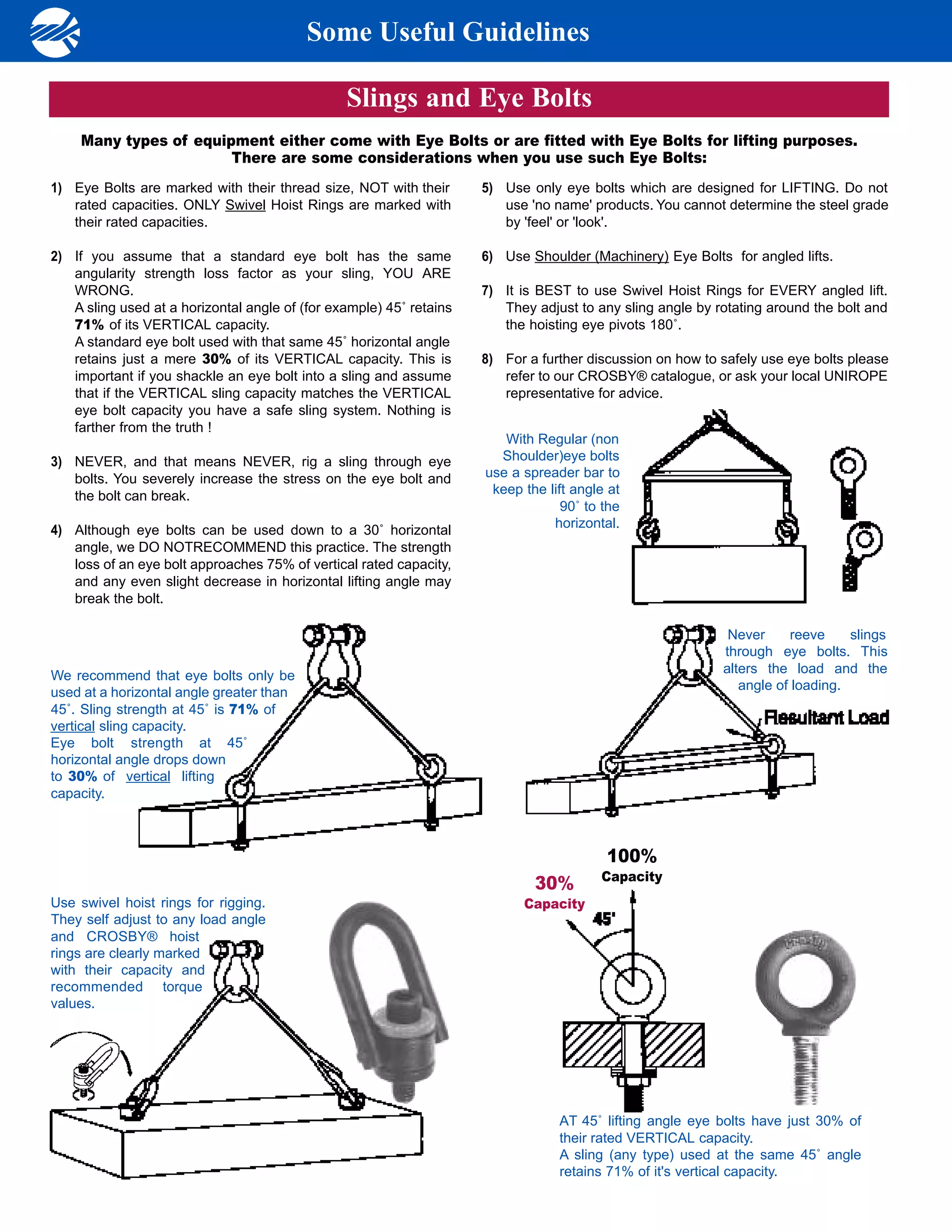

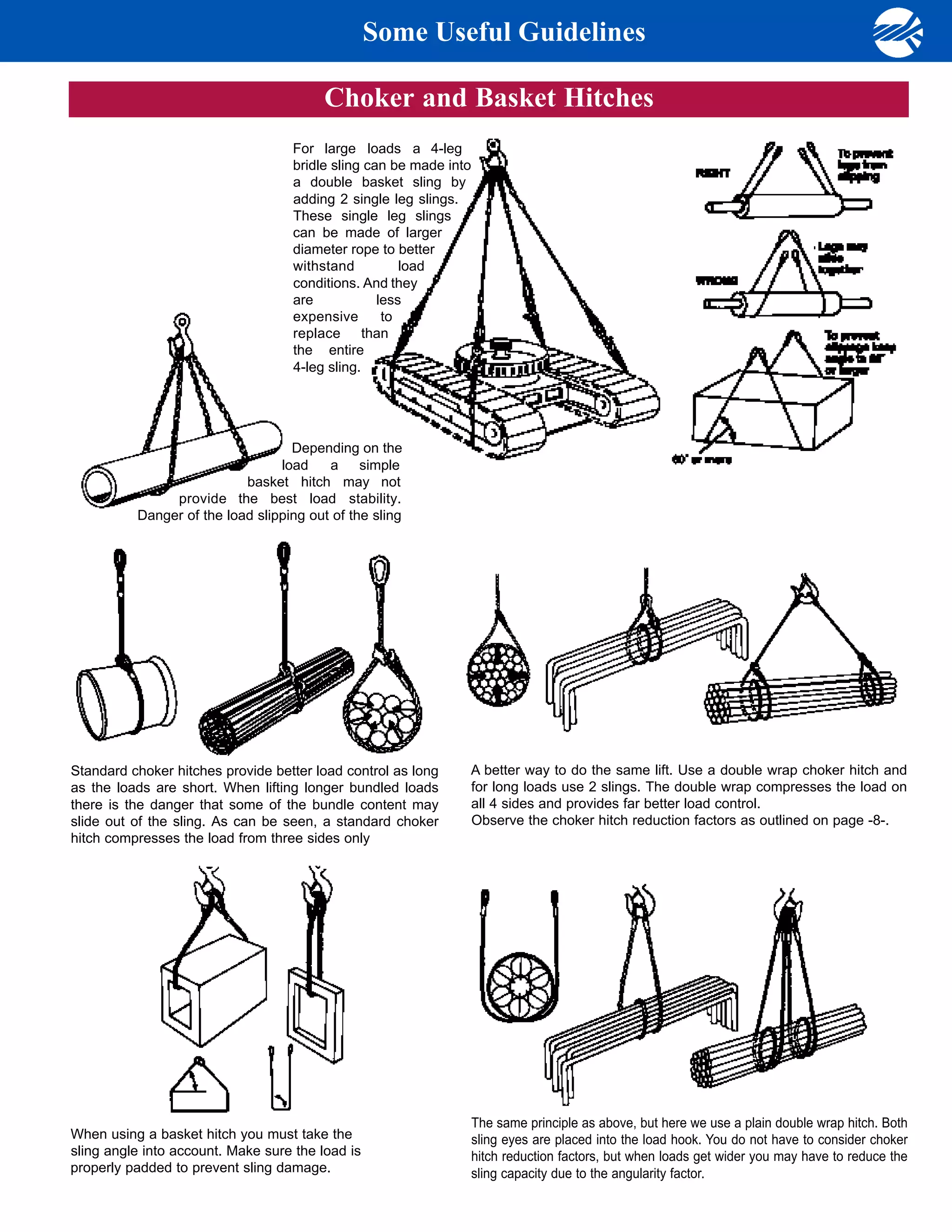

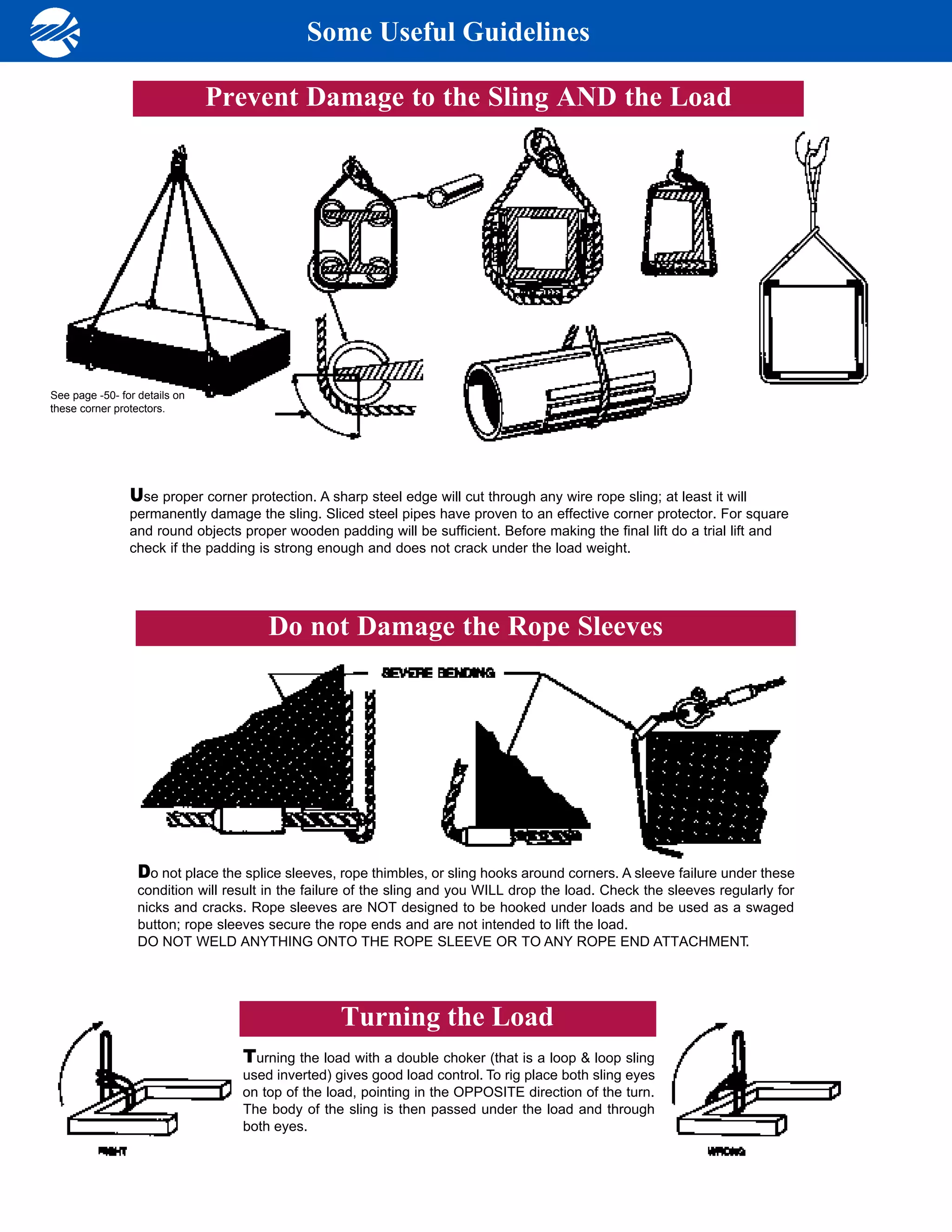

Use multiple single leg slings to wrap around off-center loads for better stability. Secure all loose equipment before lifting. When using eye bolts or slings, be aware that their capacity decreases significantly at angled loads. Use proper padding and hitches to control loads and prevent damage.