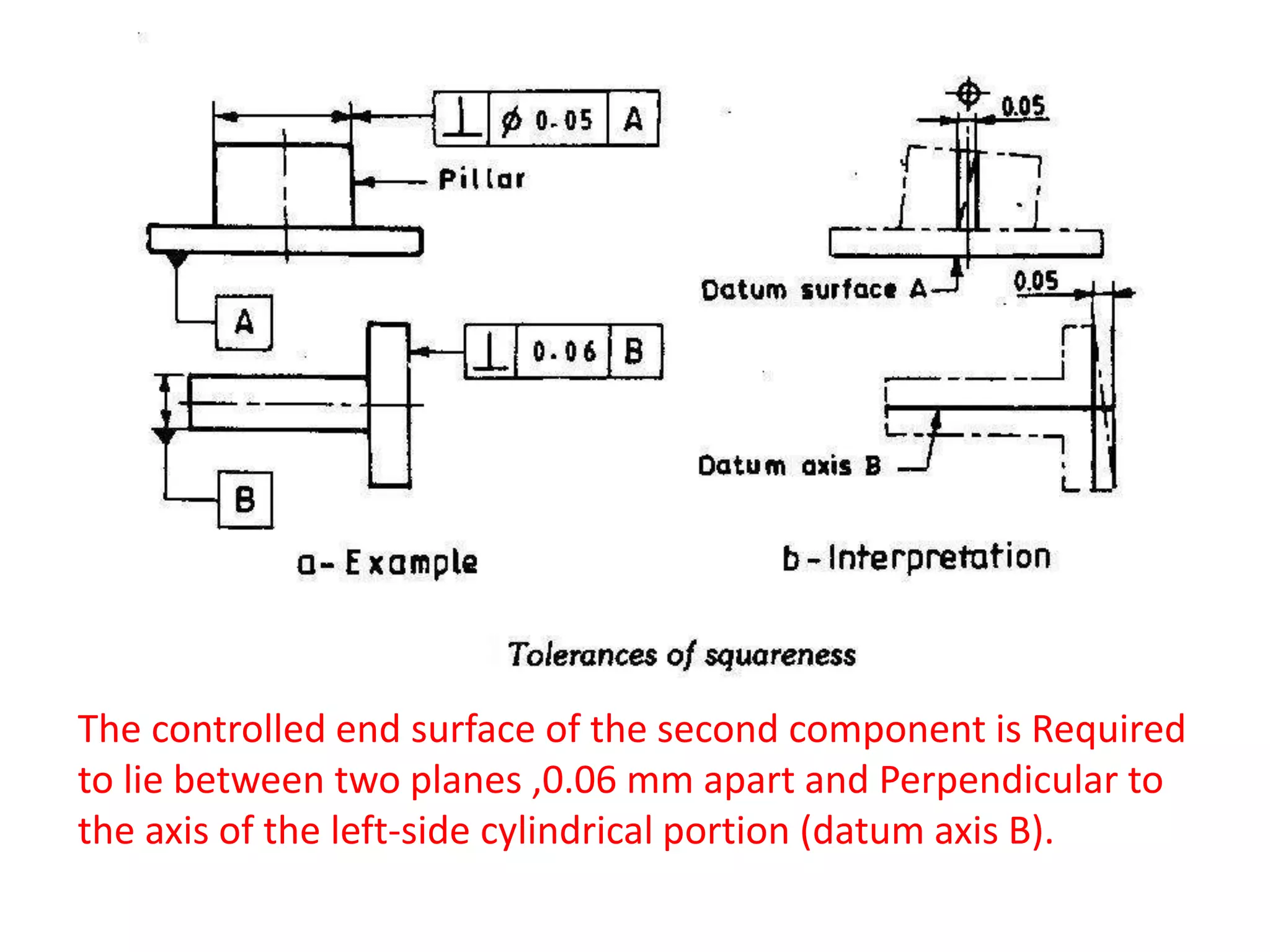

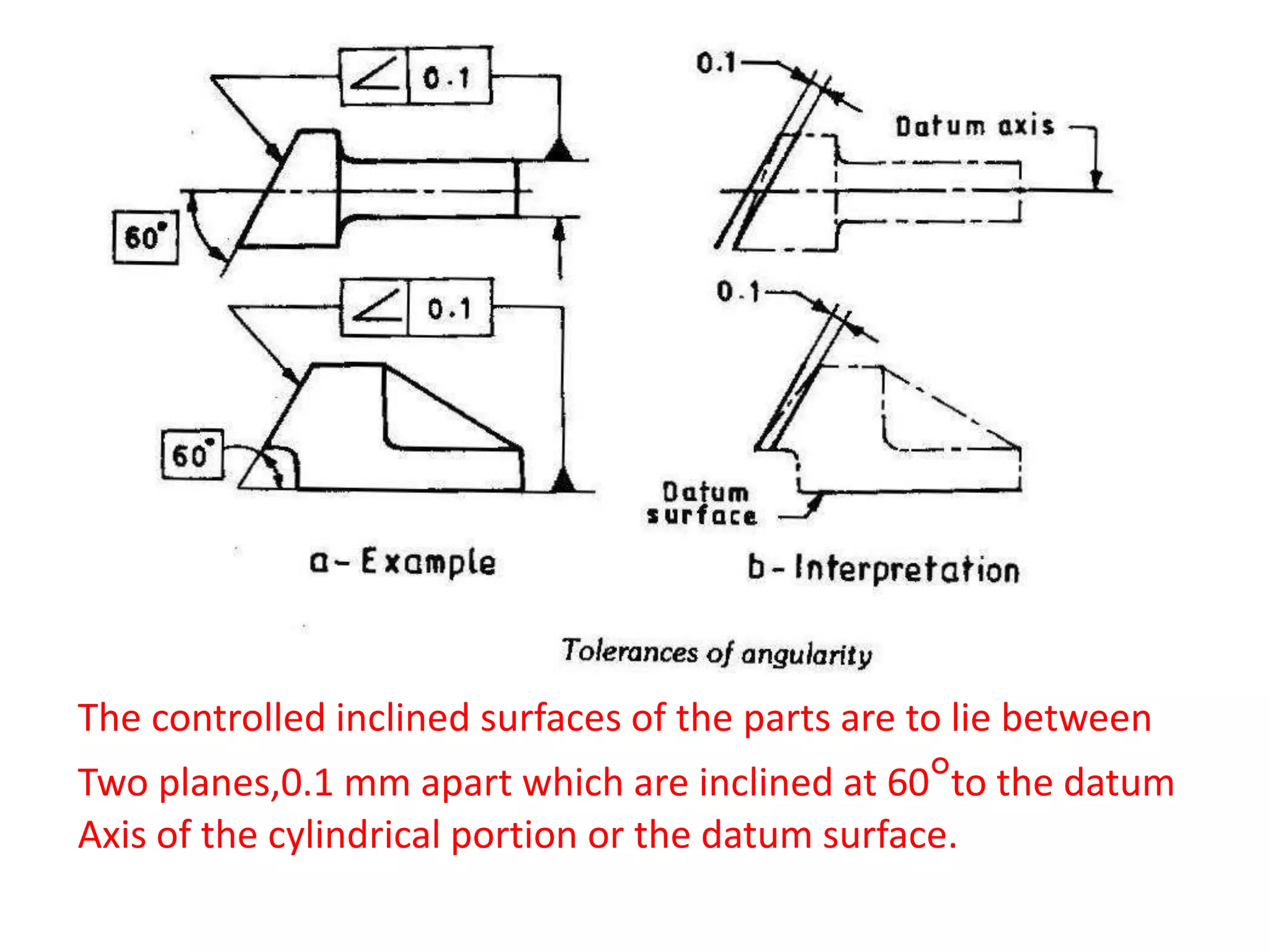

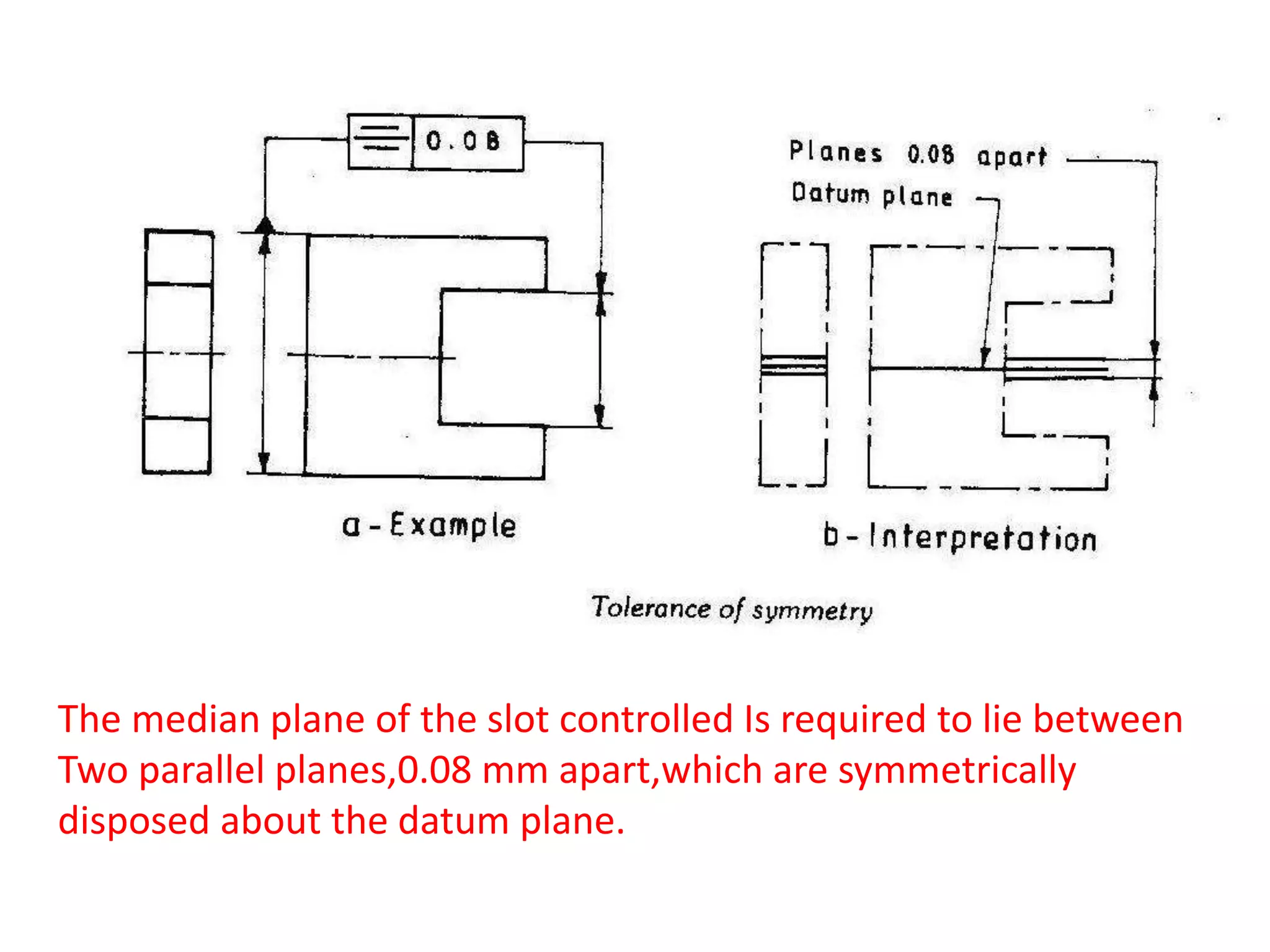

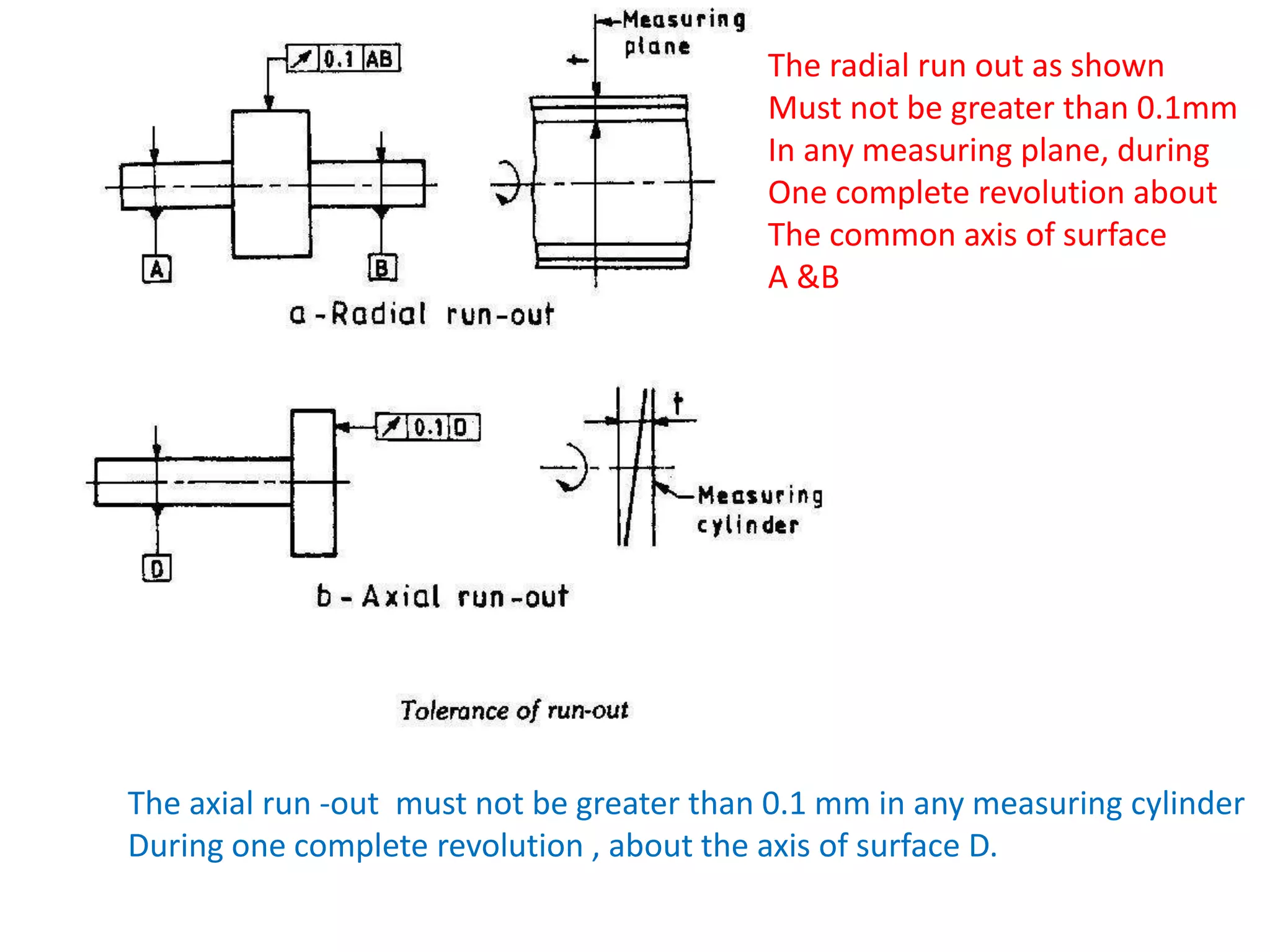

The document describes geometric dimensioning and tolerancing specifications for various features of mechanical parts. Tolerances are provided for surfaces, profiles, circles, axes of holes, cylindrical portions, slots, and run-out measurements, specifying that the controlled features must lie or be contained within defined spaces that are a certain narrow distance apart. Dimensions range from 0.02mm to 0.1mm. Datum features are also referenced.