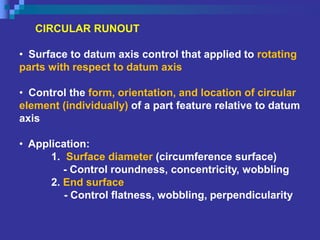

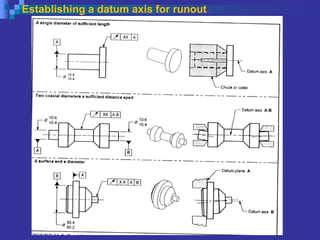

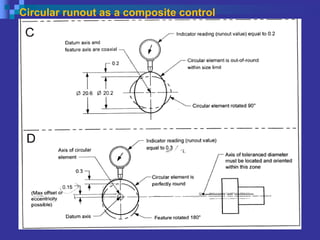

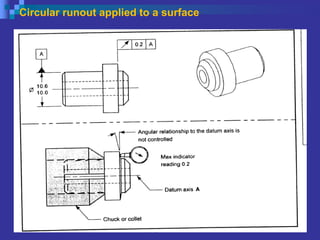

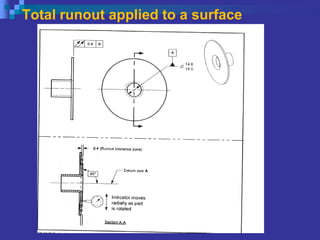

This document discusses circular and total runout tolerances for rotating parts. Circular runout controls the form, orientation, and location of individual circular elements relative to a datum axis, and is used for surfaces like diameters and end faces. Total runout controls all surface elements simultaneously relative to the datum axis, and is used for features like cylindrical surfaces and end faces. Both aim to control balance, vibration, and concentricity during rotation.