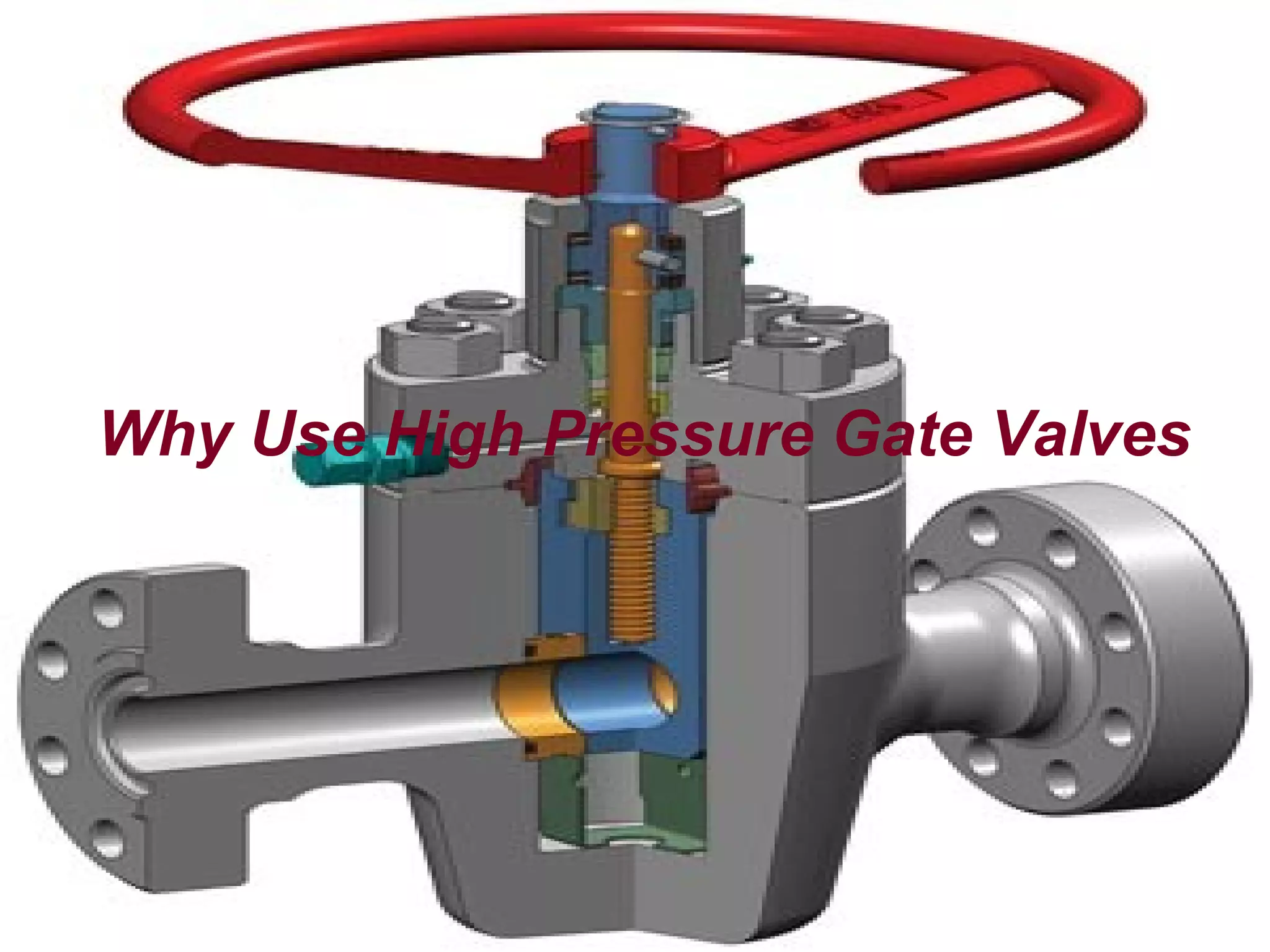

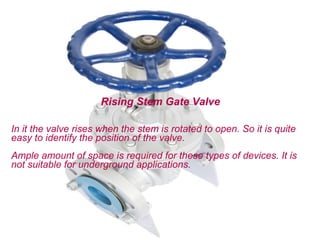

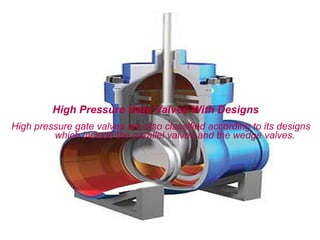

Gate valves are mainly used in high pressure areas to stop or start water flow but not regulate it. They are durable and cost-effective. There are two main types - rising stem valves where the stem rises when open, and non-rising stem valves which are more suitable for confined spaces. Gate valves come in different designs, sizes, and materials to suit various purposes and applications like controlling powder flow or collecting dust.