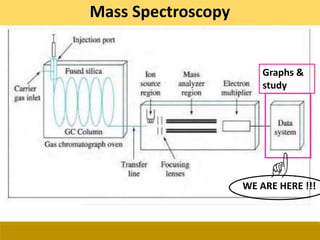

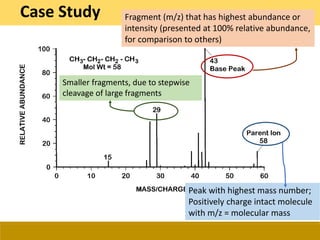

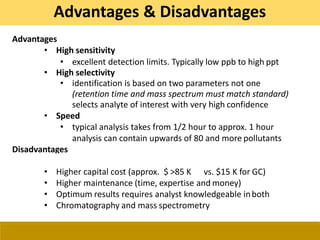

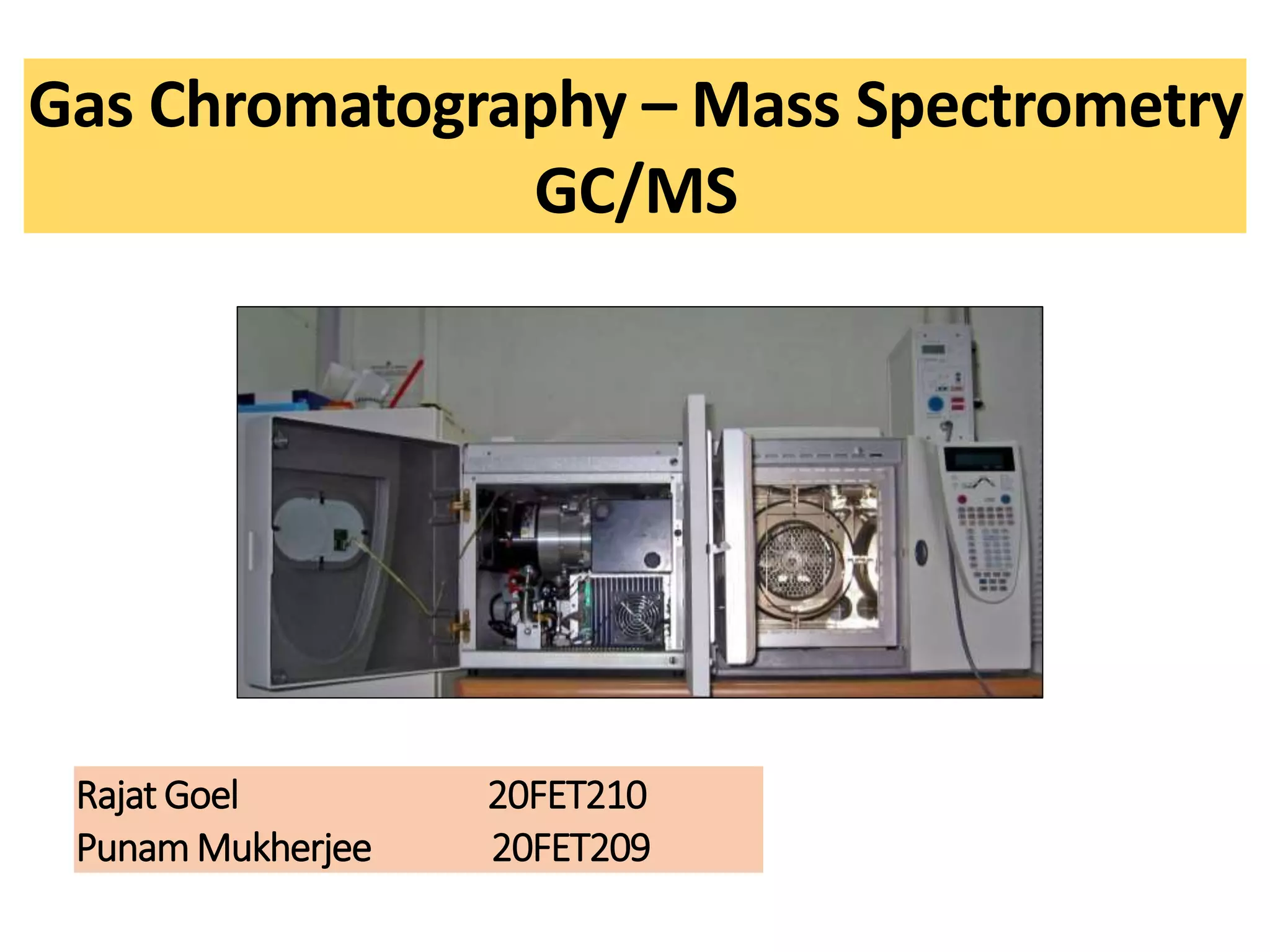

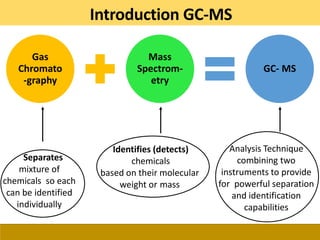

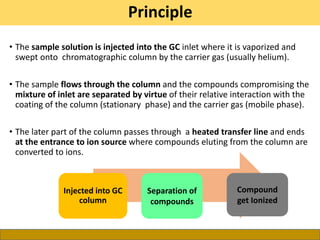

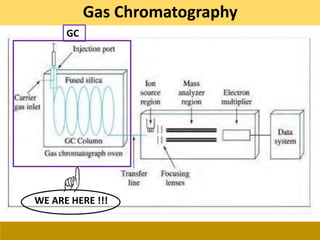

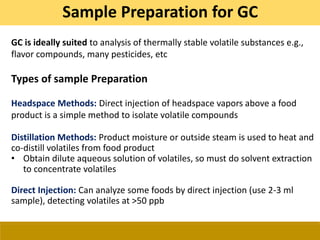

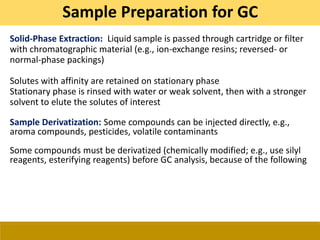

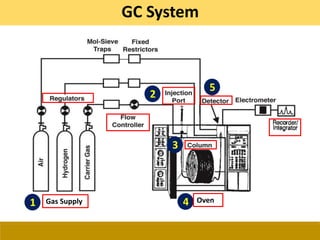

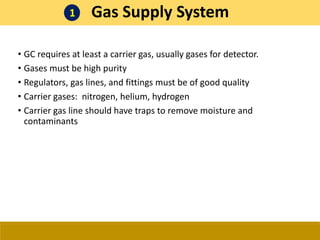

This document provides a comprehensive overview of gas chromatography-mass spectrometry (GC-MS), detailing its principles, working mechanisms, and applications in chemical analysis. It explains sample preparation techniques, types of gas supplies, column designs, and various interfacing methods between GC and MS. The document also discusses the mass spectrometry process, ionization methods, and the advantages and disadvantages of GC-MS analysis.

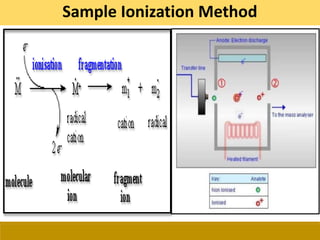

![Ionization

method

Typical

Analytes

Sample

Introduction

Mass

Range

Method

Highlights

Electron Impact (EI)

Relatively

small

volatile

GC or

liquid/solid

probe

to

1,000

Daltons

Hard

method

versatile

provides

structure

info

Chemical Ionization (CI)

Relatively

small

volatile

GC or

liquid/solid

probe

to

1,000

Daltons

Soft

method

molecular

ion peak

[M+H]+

Electrospray (ESI)

Peptides

Proteins

nonvolatile

Liquid

Chromatography or

syringe

to

200,000

Daltons

Soft

method

ions often

multiply

charged

Sample Ionization Method](https://image.slidesharecdn.com/gc-ms-210131160457/85/Gas-Chromatography-and-Mass-Spectroscopy-23-320.jpg)