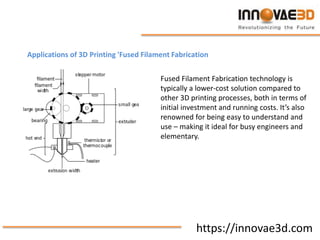

Fused filament fabrication (FFF), also known as fused deposition modeling (FDM), is an additive manufacturing process that involves pushing thermoplastic material through a heated nozzle to create objects layer by layer. It is widely used in manufacturing for rapid tooling, prototyping, and education due to its lower costs and ease of use. Key features of FFF printers include heated build plates and efficient material handling, enabling strong, lightweight parts to be produced quickly.