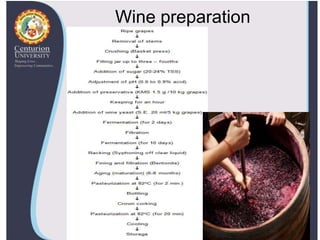

Fermented beverages such as wine, cider, and champagne are produced through the alcoholic fermentation of fruits and grains by yeast. They provide health benefits by supporting digestive health and containing probiotics. Examples have been produced for thousands of years from grapes, apples, and other fruits rich in natural sugars and acids suitable for fermentation. Unfermented beverages like fruit juices are extracted from fruits, clarified to remove pulp, and preserved through pasteurization, refrigeration, or addition of preservatives to prevent alcoholic fermentation. Common products include juices, squashes, cordials, and syrups produced through processes like extraction, clarification, preservation, and bottling.