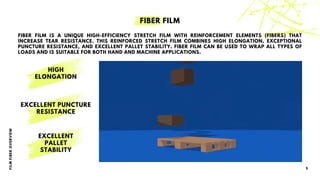

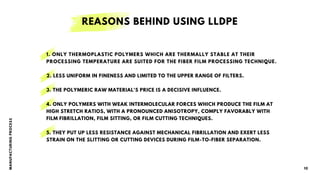

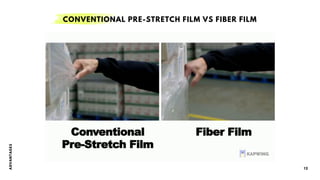

This document presents information on fiber film, a unique reinforced stretch film made from low linear density polyethylene. Fiber film combines high elongation with exceptional puncture resistance and pallet stability. It is produced using a process that transforms polyethylene into reinforcement fibers to greatly increase tear resistance and durability. Fiber film provides benefits over conventional stretch film like reduced costs, superior pallet stability, waste reduction, and being 100% recyclable.