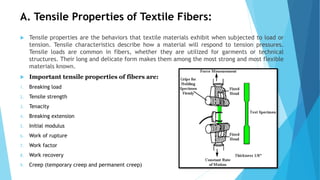

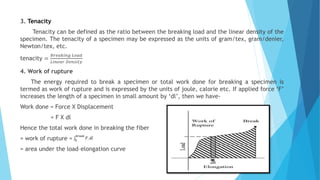

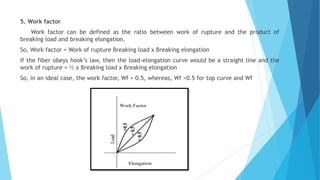

This document provides an overview of the mechanical properties of textile fibers, including tensile, flexural, torsional, and frictional properties. It discusses the importance of mechanical properties in determining fiber and fabric qualities. The key tensile properties described are breaking load, tensile strength, tenacity, breaking extension, initial modulus, work of rupture, and creep. Flexural properties examined include flexural rigidity and bending modulus. Important torsional properties mentioned are torsional rigidity and breaking twist. The presentation concludes by noting frictional properties impact yarn processing.