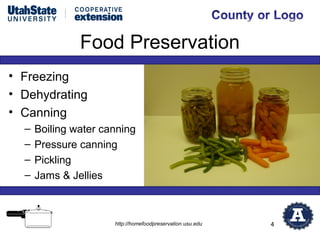

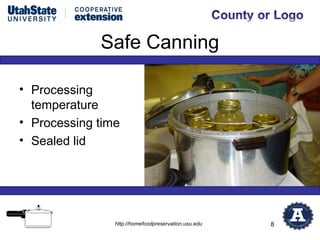

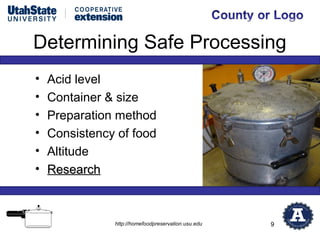

This document provides instructions for modifying and presenting a slideshow on home food preservation. It discusses copyright permissions, how to modify slide elements like logos and footers, and how to delete instructional slides before presenting. The document contains 33 slides on topics related to food preservation, including methods like freezing, dehydrating, and canning. Key canning topics covered are determining safe processing methods based on acid level, altitude, and recipes.

![Instructions to modify presentation

1. Copyright: Permission is granted for all use/reuse by U.S.U. Extension. Others may

modify the presentation only by placing their logo in the top right side of the slide master

template and adding the presenters name in the footer.

2. To modify: In PowerPoint choose [View], then [slide master], then select the last slide

down. Here you can modify the corner elements. USU Extension may replace the upper

left logo with the USU Extension logo indicating their county. All may add a logo to the

upper right corner. USU Extension may change the bottom left graphic and the footer.

3. To change the footer: Choose [Insert][Header-Footer] and type your footer as a

replacement for the existing footer. Extension staff should consider placing their web

address and phone number here.

4. When finished editing delete this instructional slide before presenting. Please do not

delete any other slides.

5. Please report errors or needed corrections to brian.nummer@usu.edu – Thanks.

http://homefoodpreservation.usu.edu 2](https://image.slidesharecdn.com/foodpreservationpresentation-120924075841-phpapp02/85/Food-preservation-presentation-2-320.jpg)