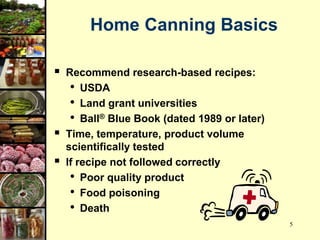

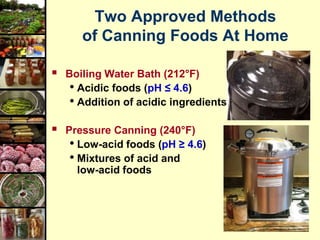

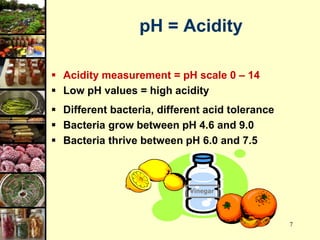

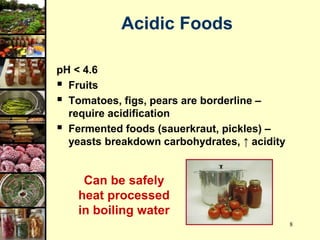

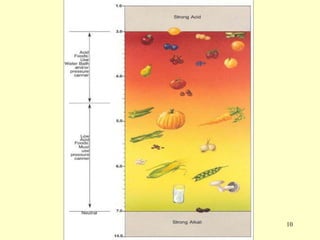

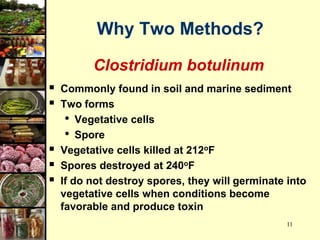

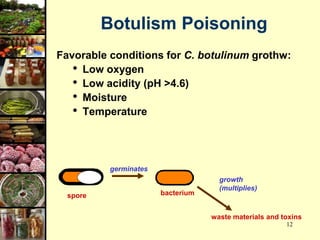

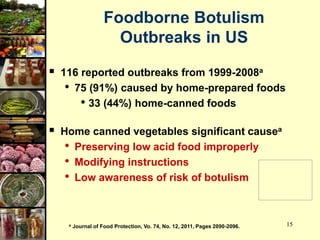

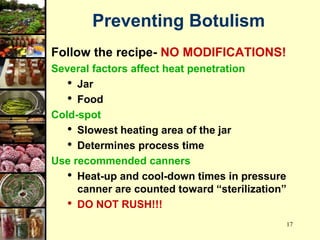

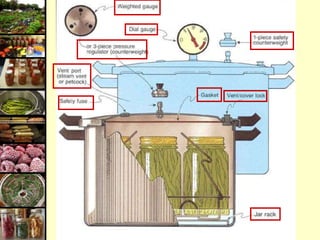

This document provides an overview of food preservation methods including canning, freezing, and drying. It focuses on canning basics and safety. The key methods are boiling water bath canning for acidic foods and pressure canning for low-acid foods to prevent botulism poisoning from Clostridium botulinum bacteria. Pressure canning is required to reach the higher 240°F temperature needed to destroy spores in low-acid foods. Following research-tested recipes, recommended processes, and equipment is essential for safe home food preservation.