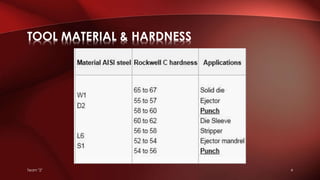

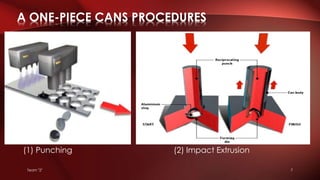

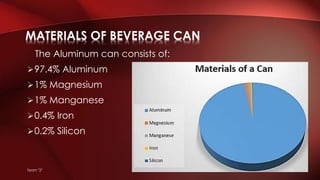

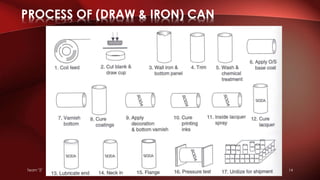

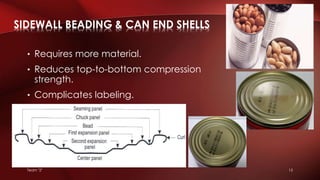

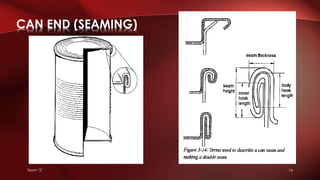

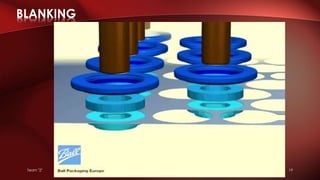

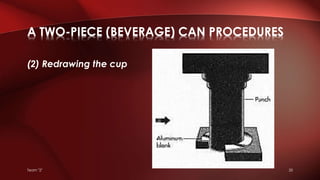

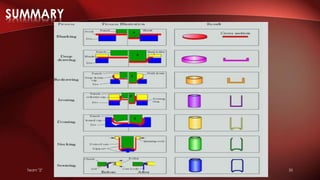

The document provides an overview of can manufacturing, detailing the history, types of cans (one-piece, two-piece, and three-piece), and materials used, particularly emphasizing the shift to aluminum in 1957 for its cost-effectiveness and malleability. It describes the complex manufacturing processes for each type of can, including steps such as drawing, trimming, and quality assurance. The conclusion highlights the advanced nature of the aluminum beverage can production process and the importance of optimizing materials and tooling.