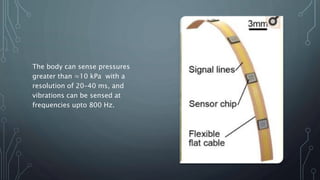

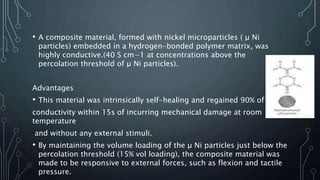

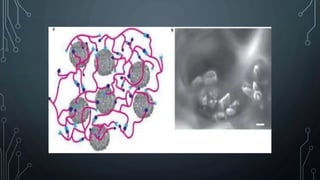

Electronic skin, or e-skin, is a thin flexible material designed to mimic the properties of human skin, especially sensitivity to pressure and temperature. E-skin uses sensors and electronics to sense touch and stimuli like human skin. Researchers are developing e-skin using materials like graphene, polymers, carbon nanotubes, and nanowires embedded in flexible substrates. E-skin can sense pressure and vibrations similar to human skin. Researchers are also working on developing self-healing capabilities in e-skin through use of microcapsules containing healing agents or dynamic reversible bonds in materials. E-skin has applications in robotics, displays, healthcare for prosthetics and monitoring. The latest development is an e-skin capable of