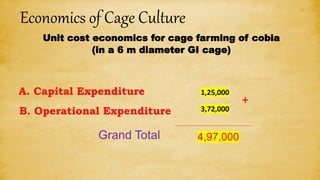

The document discusses the economics of cage culture for farming cobia fish. It provides details on the capital costs, operational costs, production estimates, and profit analysis for a single 6m diameter cage over 3 years. The analysis estimates a net profit of Rs. 1,48,280 after repaying capital costs and interest over the 3 year period.