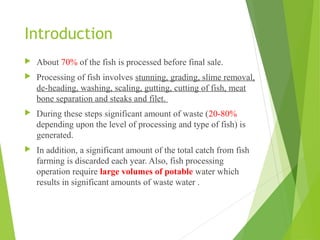

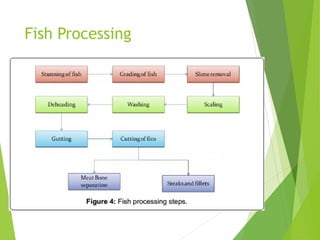

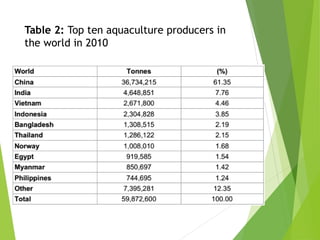

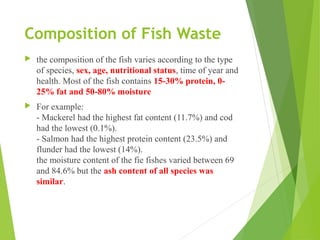

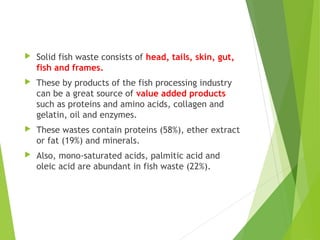

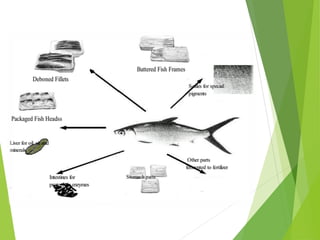

This document discusses the utilization of fish wastes from processing. Around 70% of fish is processed, generating 20-80% waste depending on the level of processing. Currently, most fish waste is disposed of in oceans, polluting the water. The document outlines current uses of fish waste including fish silage for animal feed, fish meal production, and fish sauce fermentation. It also discusses extracting proteins, amino acids, and oils from fish waste and their various industrial applications.