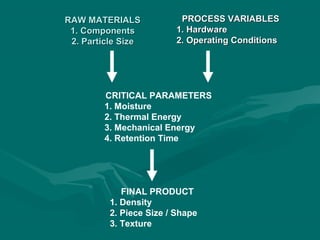

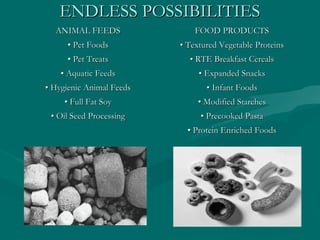

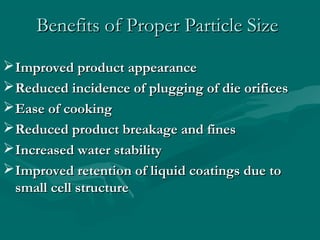

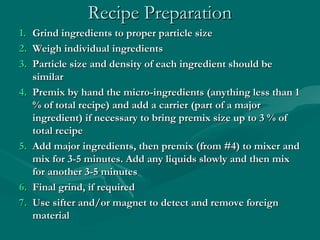

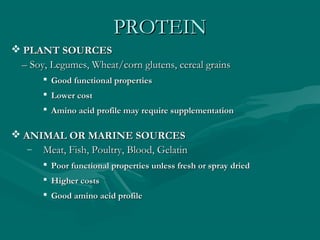

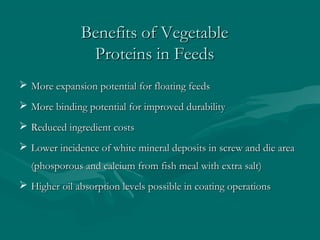

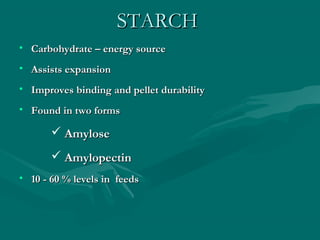

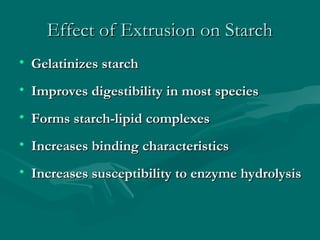

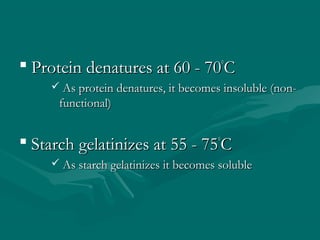

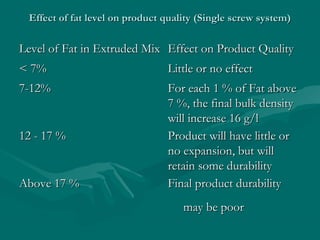

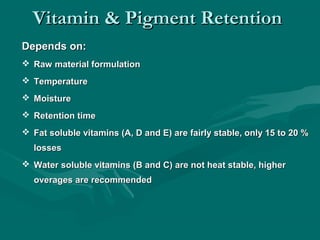

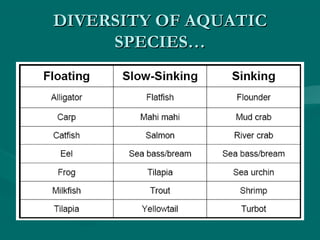

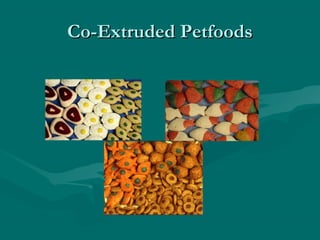

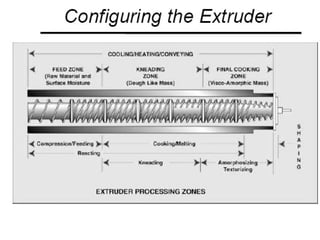

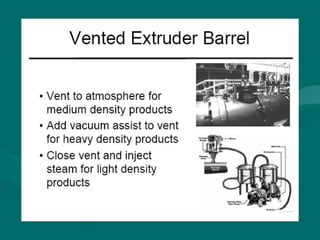

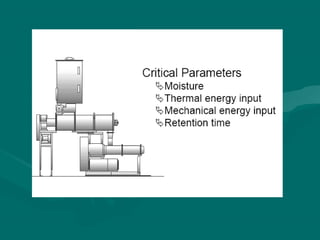

This document discusses extrusion processing for animal feed and food products. It begins by defining extrusion and describing its use in feed manufacturing. It then covers key aspects of extrusion including raw materials, process variables, critical parameters, and end products. Various applications are highlighted such as pet foods, aquaculture feeds, breakfast cereals and more. Fundamental concepts are explained like the effects of protein, starch and fat. New developments and market trends are also mentioned.