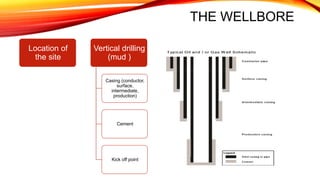

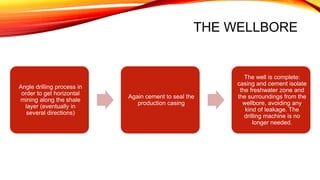

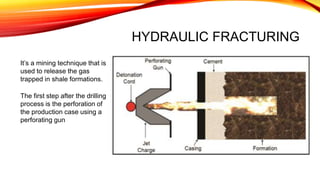

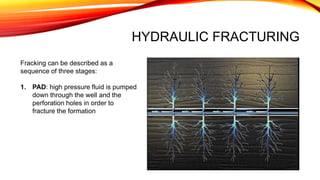

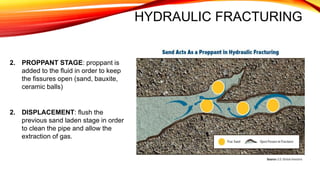

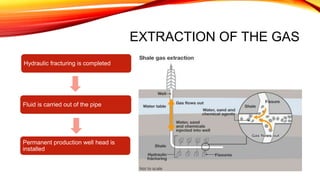

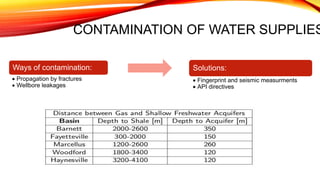

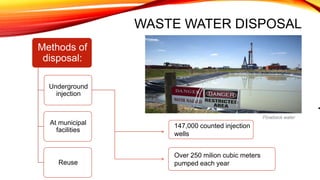

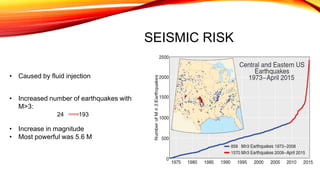

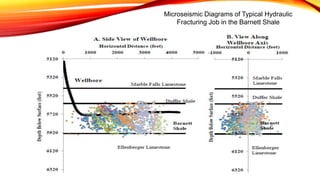

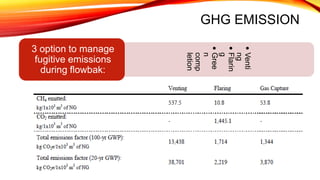

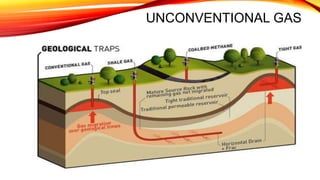

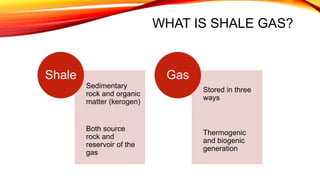

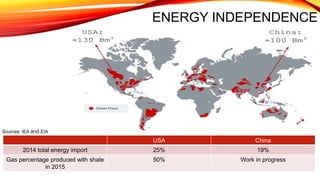

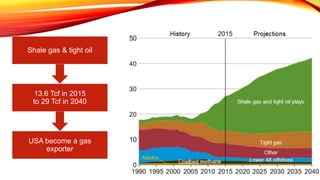

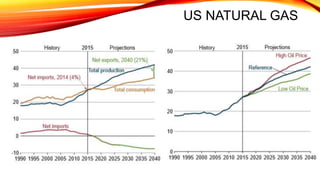

The document discusses conventional and unconventional gas extraction, focusing on shale gas and the technological advancements in drilling that make its extraction economically viable. It highlights concerns about environmental impacts, including groundwater contamination and seismic risks, along with methods for managing these risks. The document also examines the role of shale gas in energy independence for countries like the USA and Poland, and outlines the hydraulic fracturing process used to extract gas from shale formations.

![ECONOMICAL ISSUES

30% fracking companies went bankrupt in 2015 due to the oil low price

At the same time technology improvements leads to higher rates of recovery at lower costs

Oil price - WTI [USD/bbl]](https://image.slidesharecdn.com/shalegas-180615094835/85/Shale-gas-review-8-320.jpg)