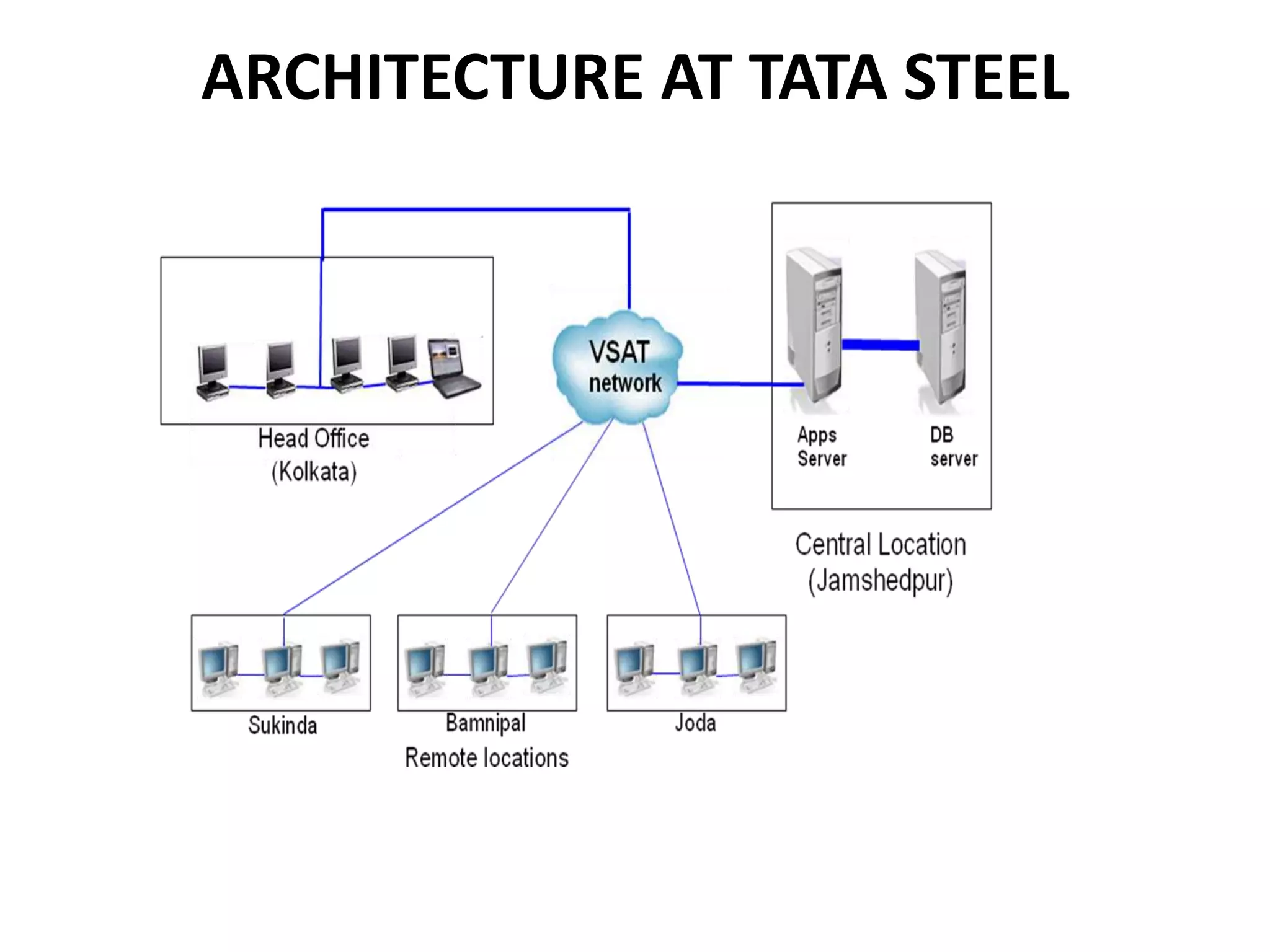

Tata Steel is India's largest integrated private sector steel company. It implemented SAP ERP across its 46 locations in 8 months, becoming one of the largest SAP implementations in India. The implementation improved customer focus, credit control, inventory management, and responsiveness. It resulted in significant cost savings, increased productivity, and improved data quality and decision making. Tata Steel saw reductions in manpower costs, inventory carrying costs, and overdue outstanding amounts.