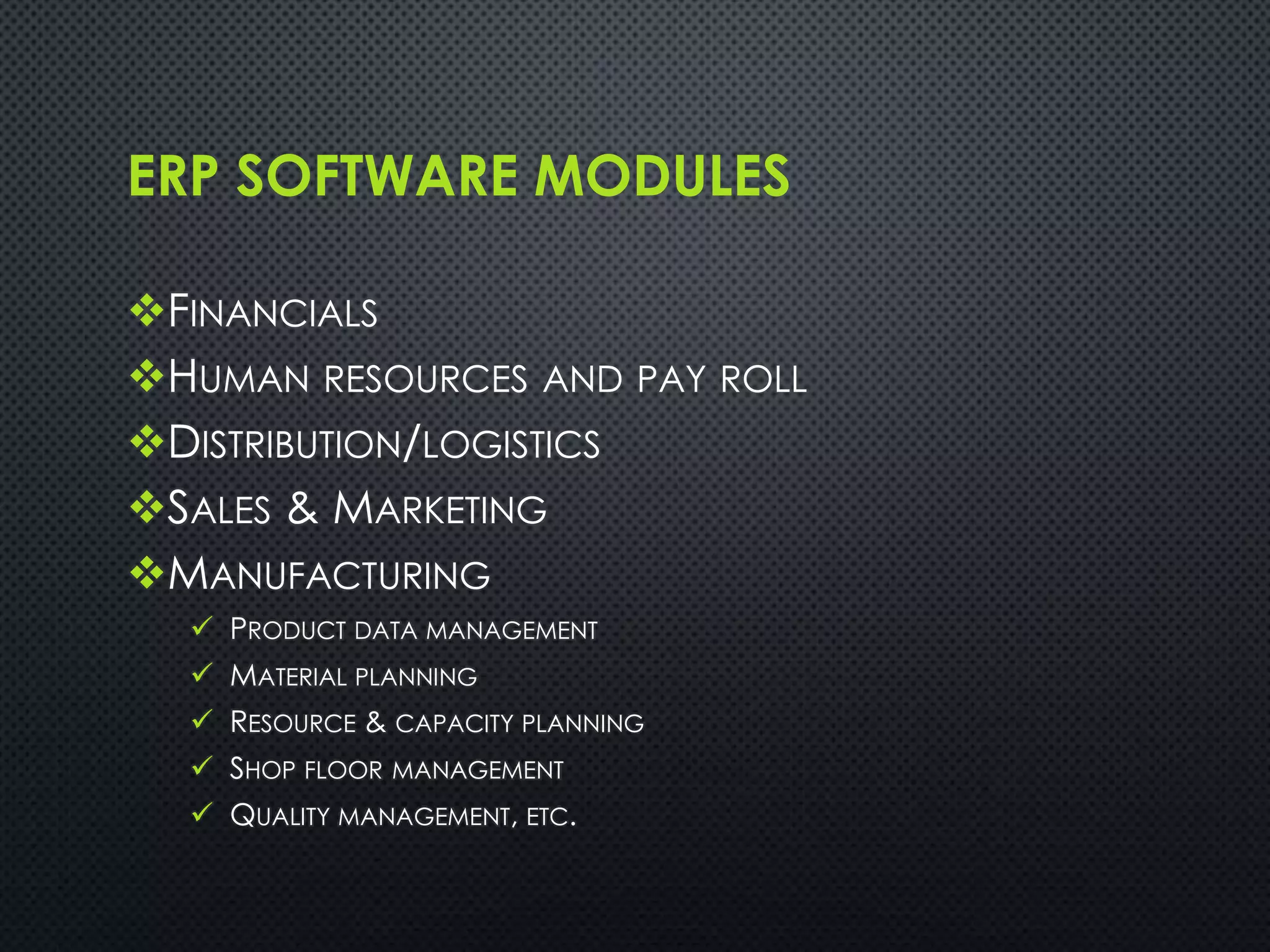

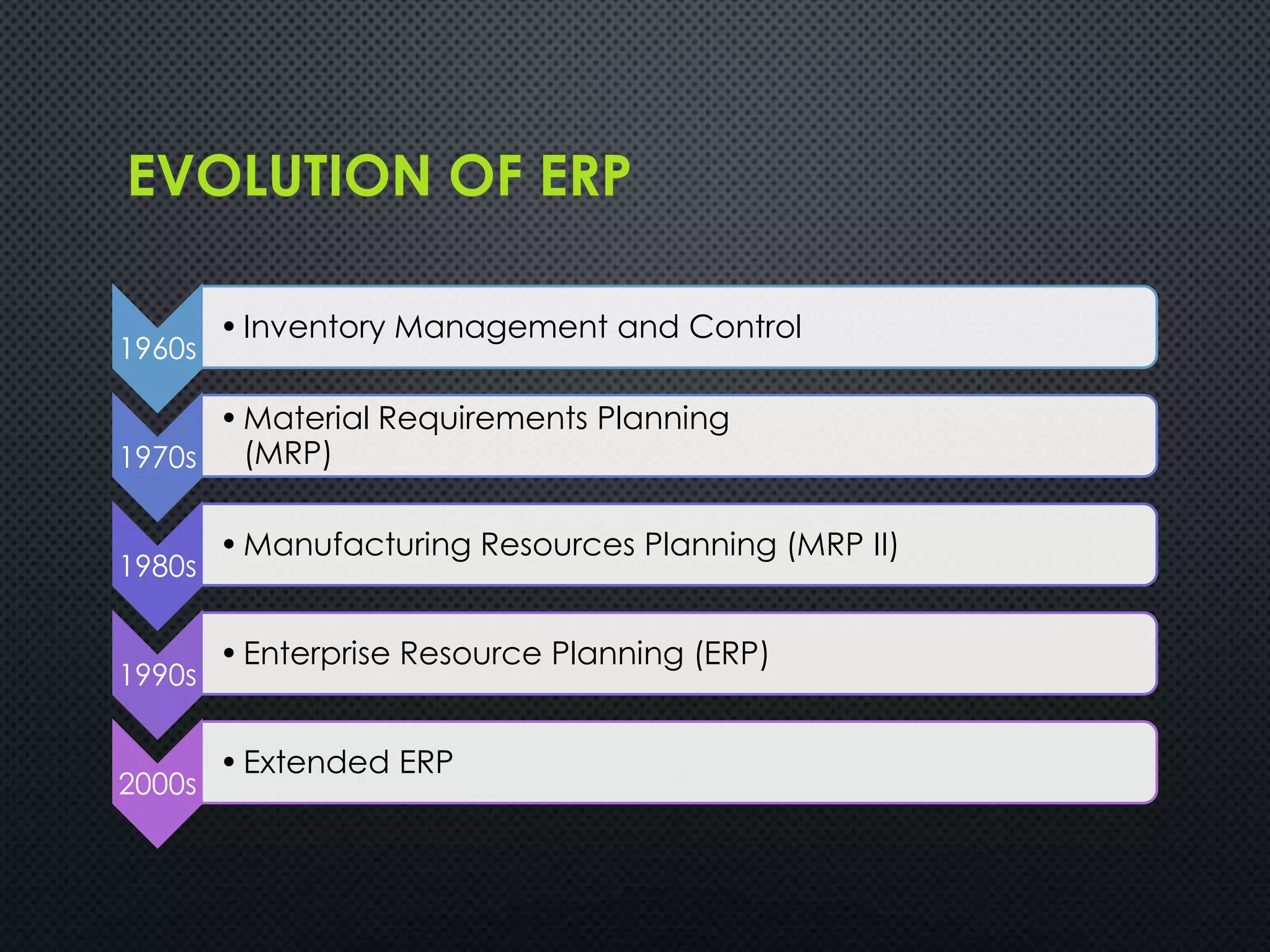

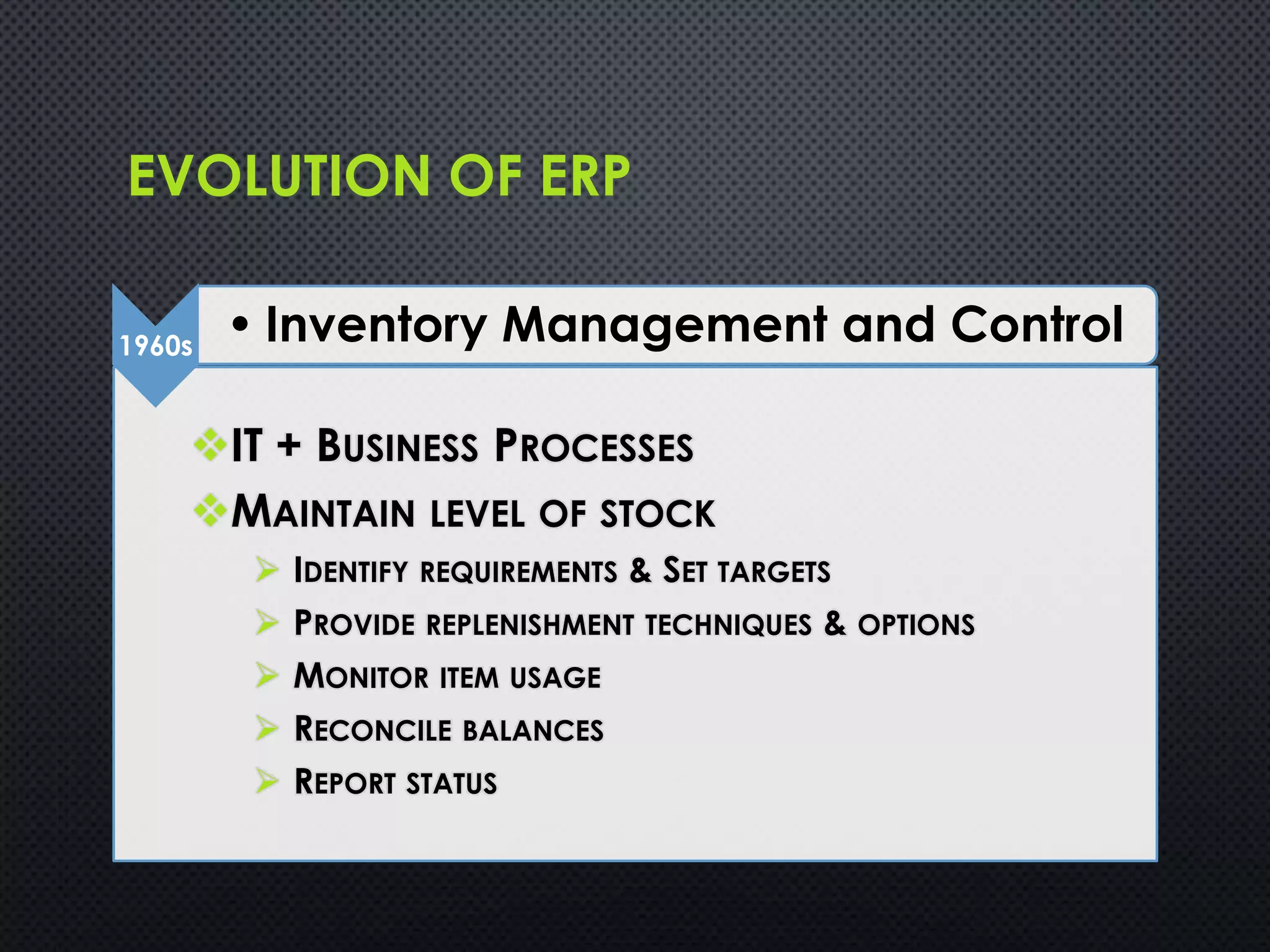

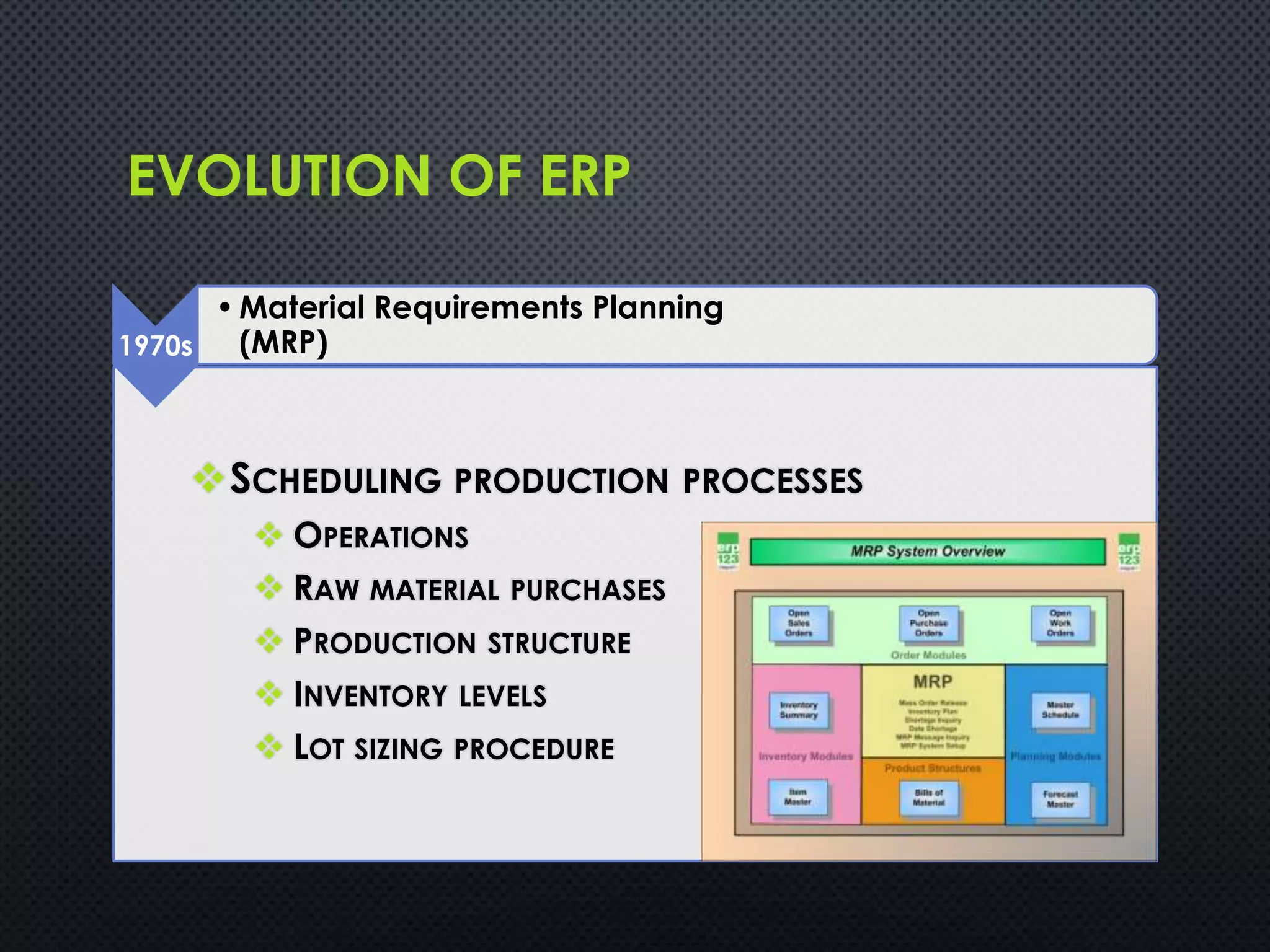

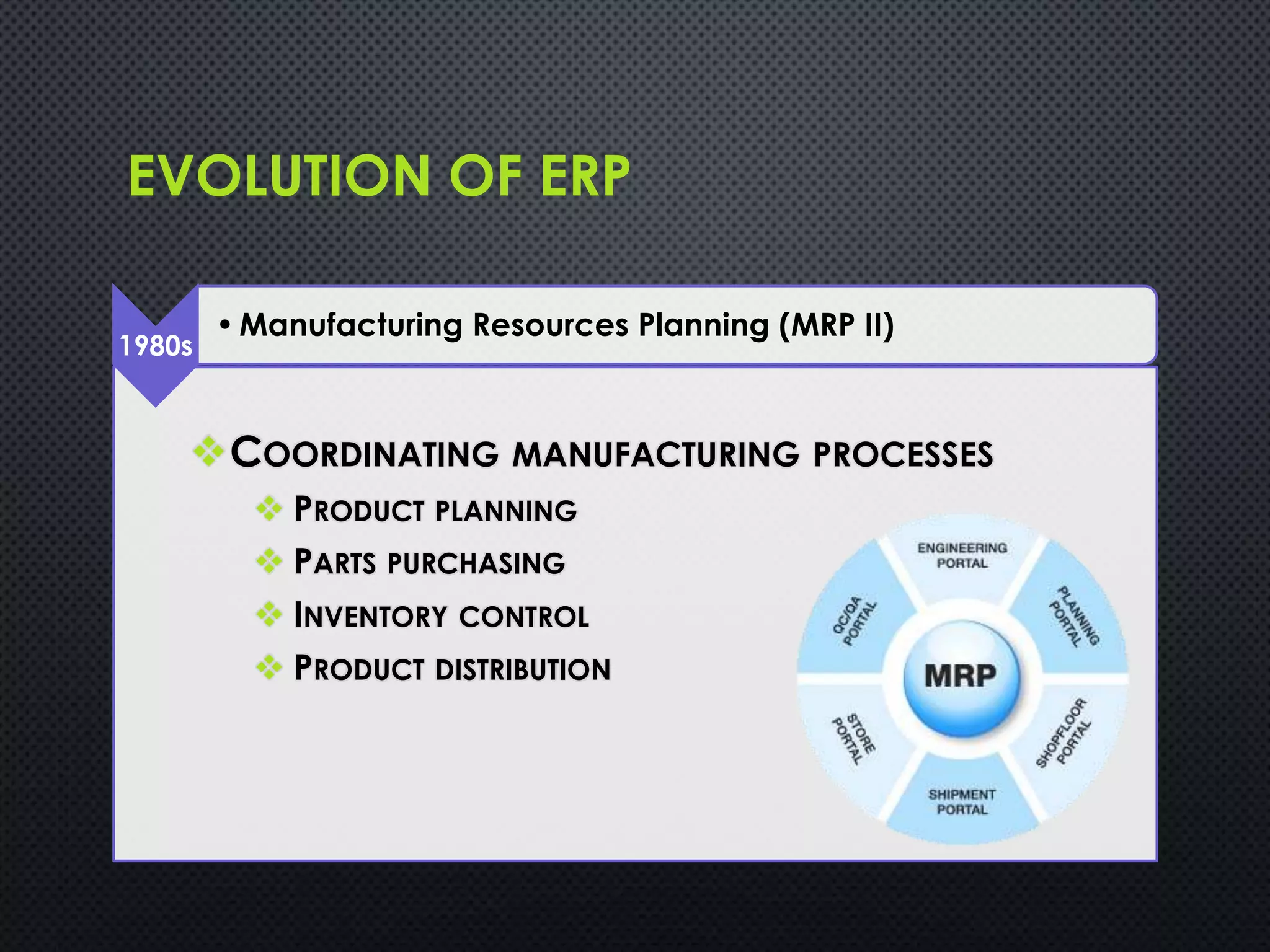

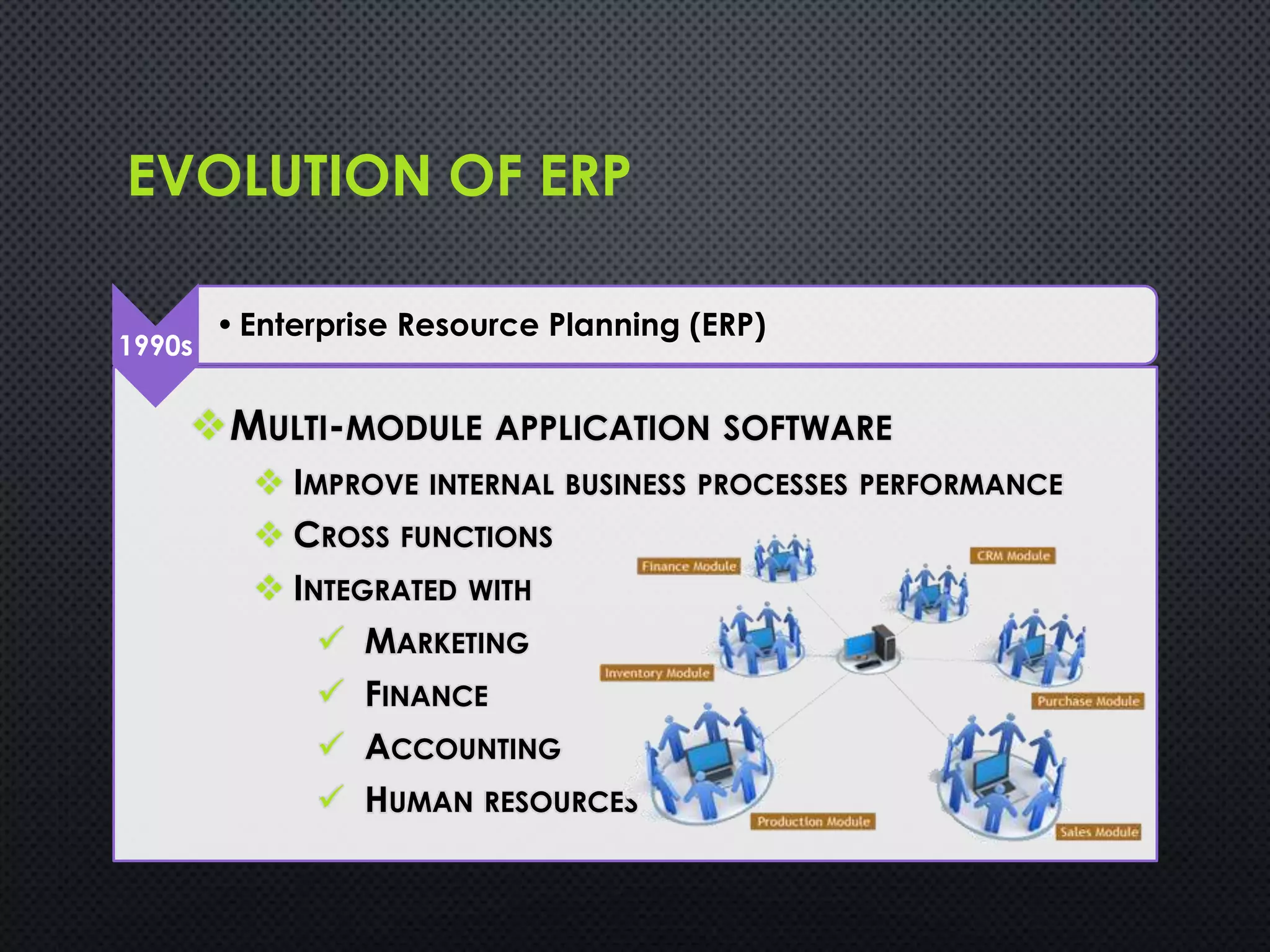

This document discusses the evolution of enterprise resource planning (ERP) systems from the 1960s to the 2000s. It describes how ERP systems originated from separate inventory management, materials requirements planning, and manufacturing resources planning systems and integrated various business functions and processes into a single software package. The document also outlines some of the key modules in modern ERP systems like financials, human resources, distribution, sales and marketing, and manufacturing.