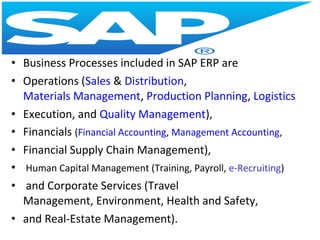

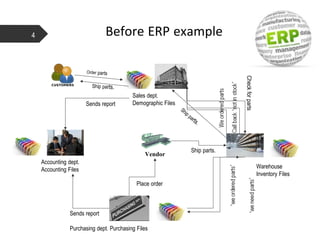

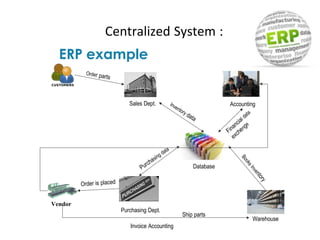

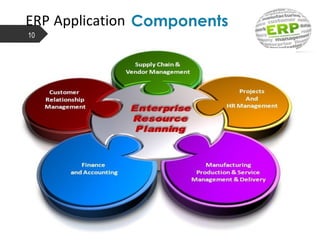

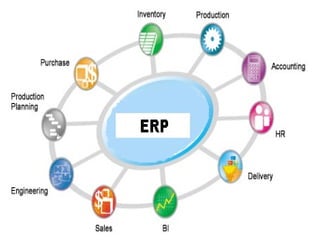

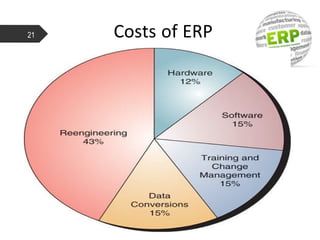

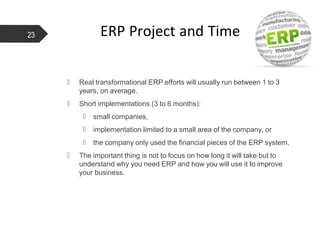

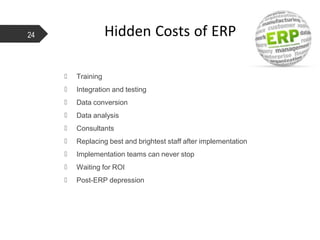

Enterprise Resource Planning (ERP) systems integrate core business processes like procurement, production, sales, and distribution across an organization. ERP combines databases from different departments into a single database accessible to all employees. It automates tasks to support business processes. Major ERP vendors include SAP, Oracle, and Microsoft. While ERP implementation provides benefits like improved integration and access to information, it also involves high costs, risks, and a long implementation time of 1-3 years.