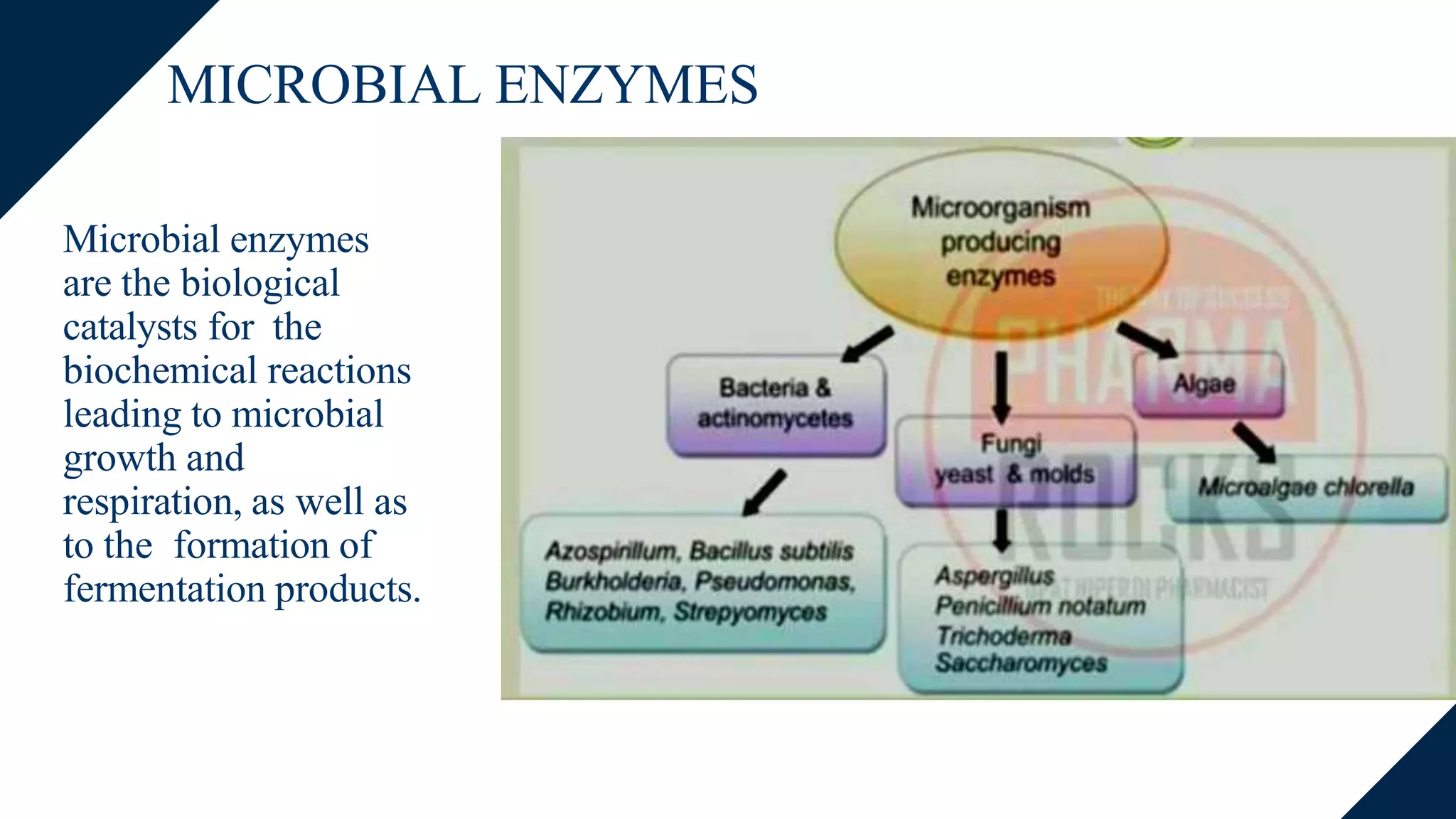

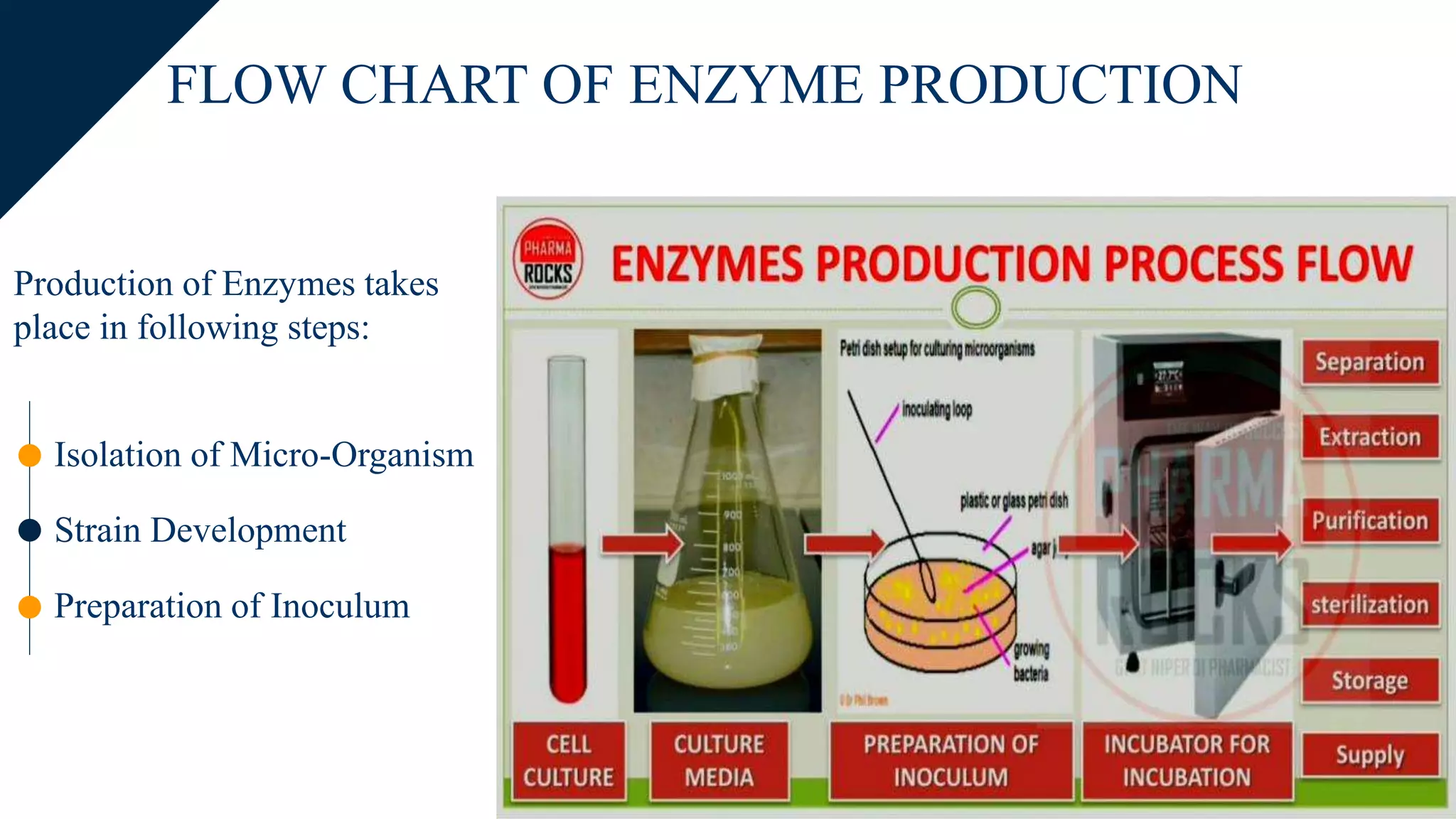

Microbial enzymes are biological catalysts produced by microorganisms that are used for various biochemical reactions. There are two main types of enzymes - adaptive and constitutive. Enzymes can be produced via submerged culture or semisolid culture methods. Semisolid culture involves growing the enzyme-producing microorganism on the surface of a moistened solid substrate, while submerged culture uses fermentation equipment like tanks. Common microbes used in enzyme production include Aspergillus species. The production process involves isolation of microorganisms, strain development, inoculum preparation, and fermentation.