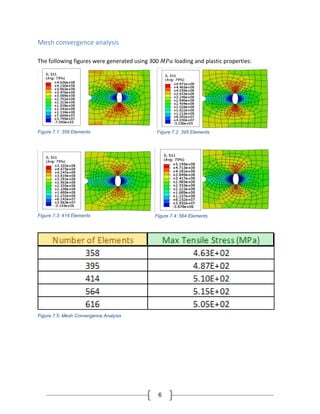

The project involved using Abaqus software to perform finite element analysis on a thin rectangular steel plate under varying loading conditions, focusing on maximum tensile stress and its location. A mesh convergence analysis was conducted to ensure accurate results, leading to the identification of maximum tensile stresses of 160.8 MPa and 883.6 MPa for 50 MPa and 300 MPa loading cases, respectively. The study provided insights into both elastic and plastic behavior of the material and calculated stress concentration factors.