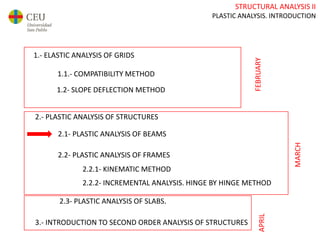

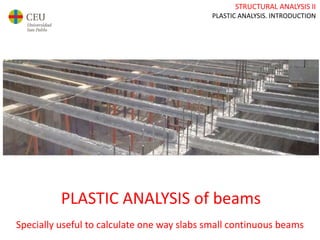

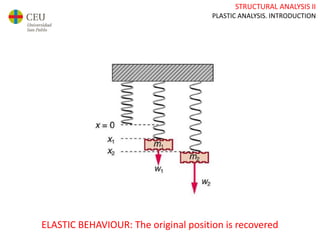

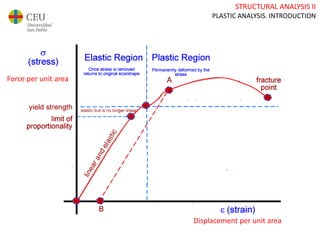

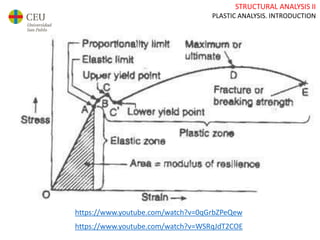

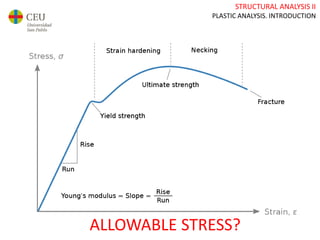

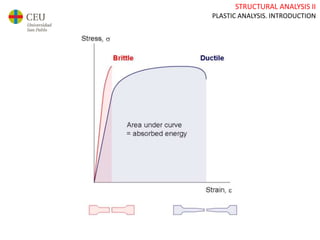

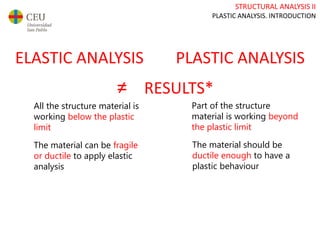

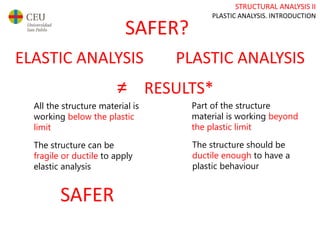

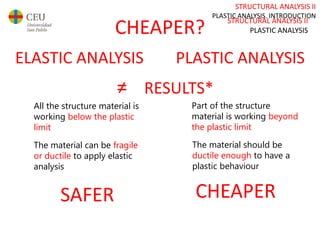

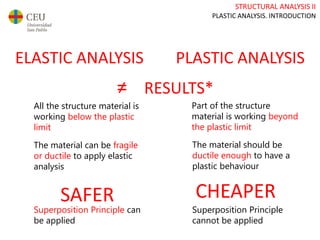

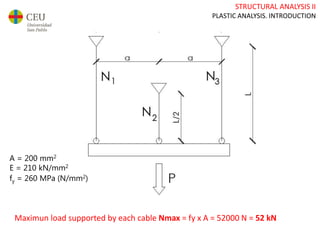

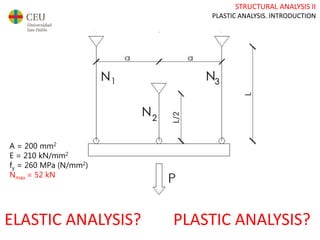

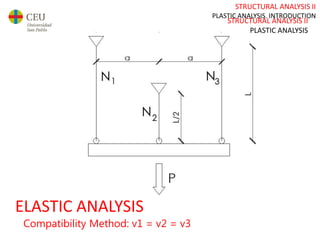

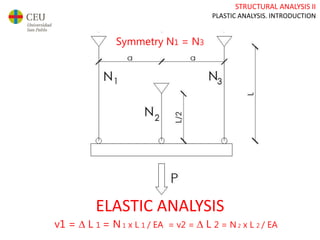

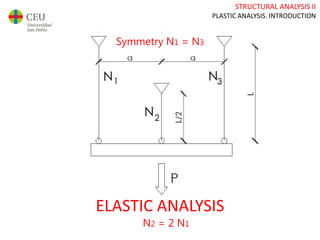

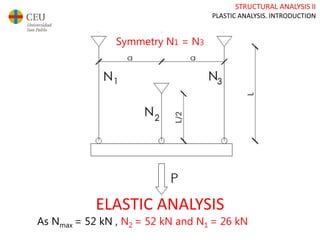

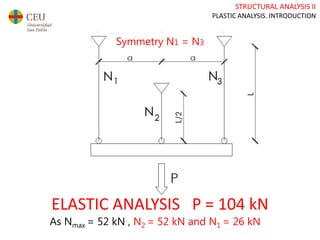

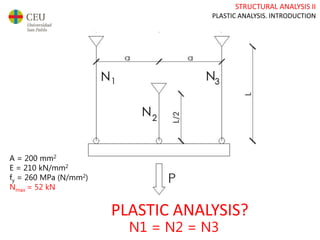

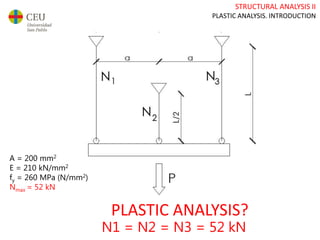

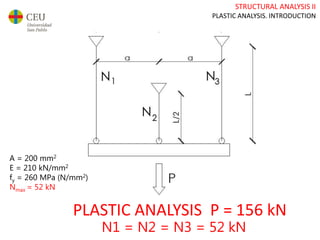

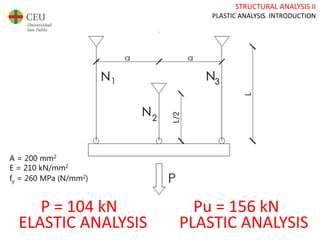

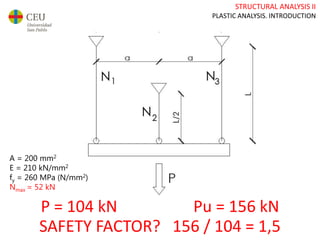

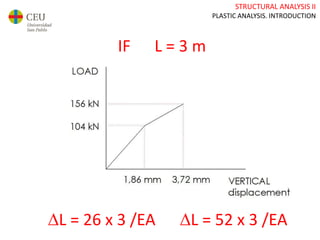

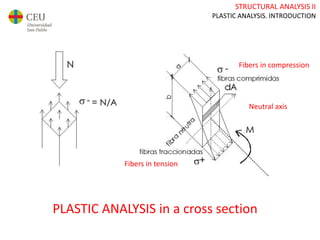

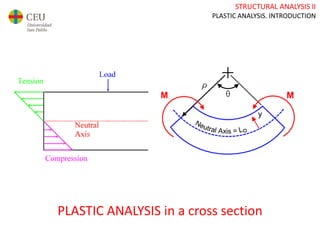

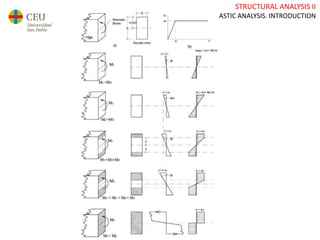

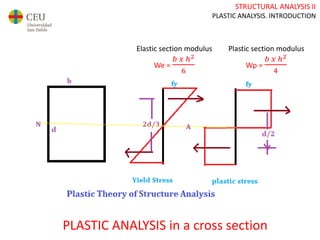

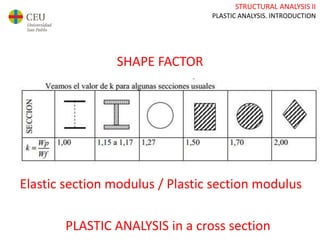

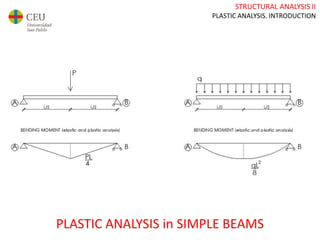

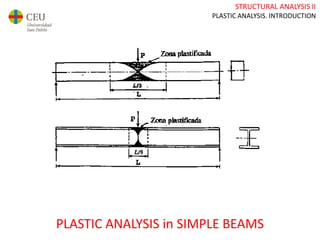

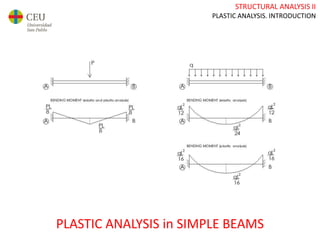

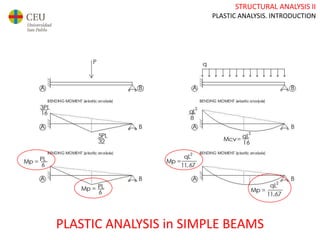

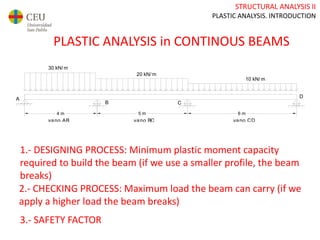

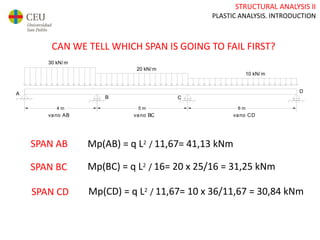

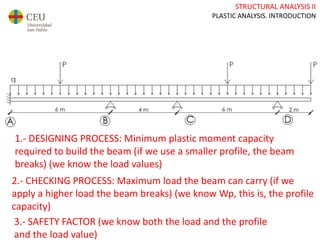

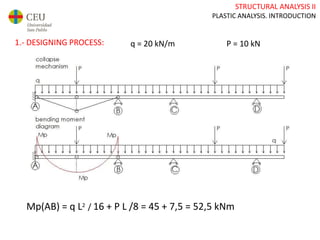

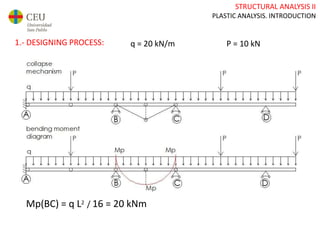

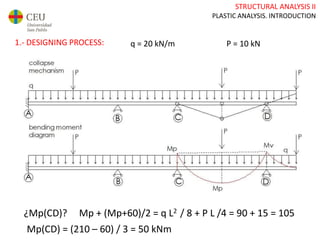

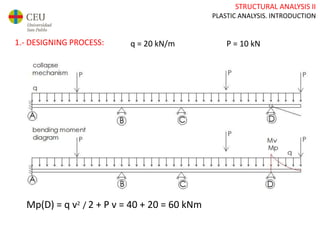

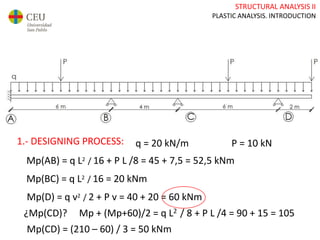

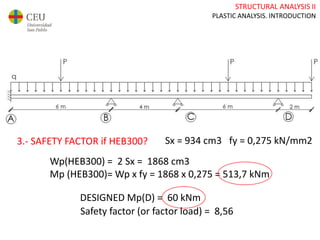

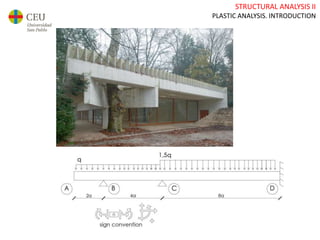

This document discusses plastic analysis of structures. It begins by introducing elastic and plastic behavior in materials. Plastic analysis is then compared to elastic analysis, noting that plastic analysis provides safer and more economical designs by allowing materials to yield while still supporting load. Methods for plastic analysis of beams, frames, and slabs are outlined. Key aspects of plastic analysis in cross-sections and simple/continuous beams are also summarized, including plastic hinge formation and required plastic moment capacities. Worked examples demonstrate how to determine minimum required plastic moments, maximum loads supported, and safety factors in plastic design.