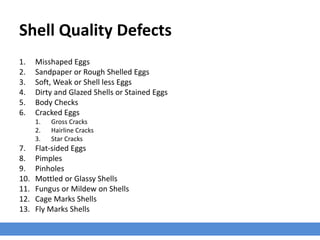

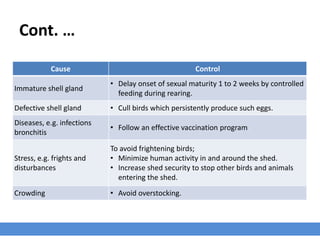

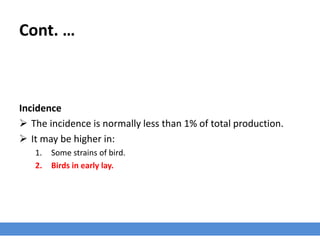

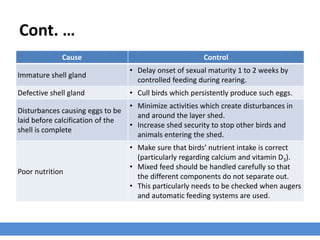

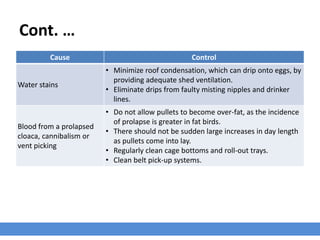

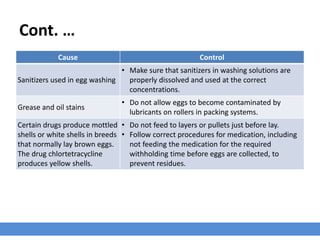

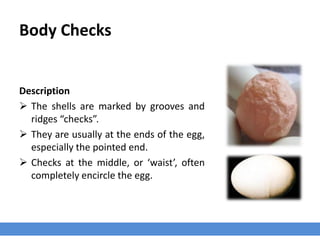

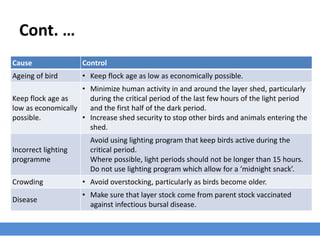

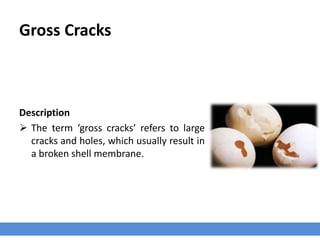

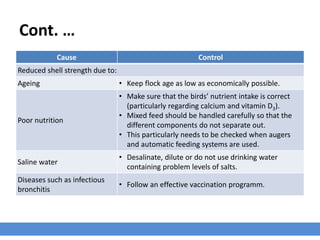

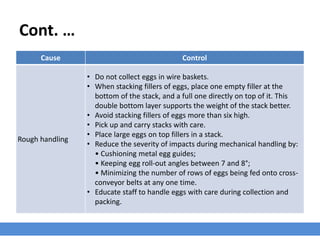

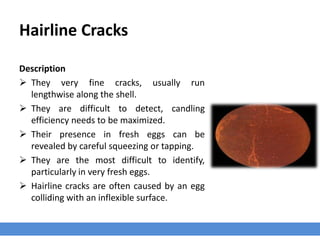

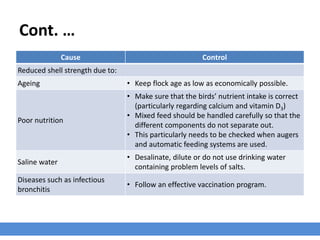

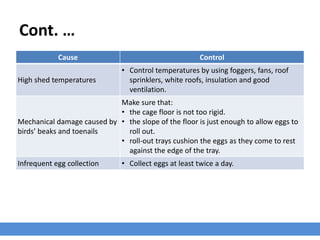

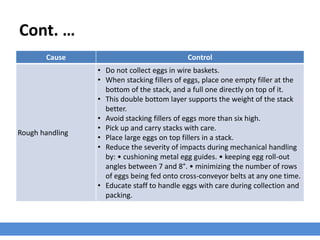

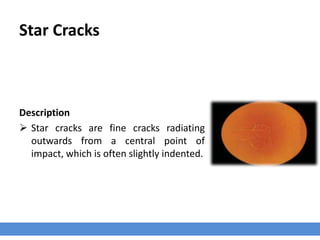

Egg shell quality issues can result in significant losses for egg producers. Up to 10% of eggs may be lost due to shell quality defects like cracks, thin shells, or dirt/stains. Poor nutrition, disease, stress, age, and rough handling can all weaken shells or damage eggs. Proper management of lighting, temperature, and hygiene are needed to support shell quality and minimize breakage losses.