This document provides an overview of several key meat processing principles and techniques:

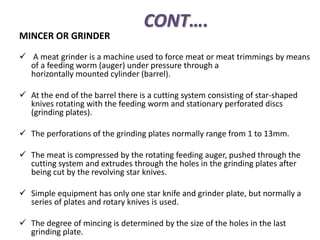

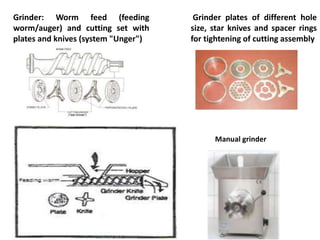

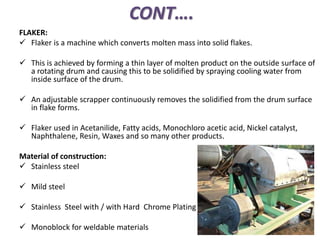

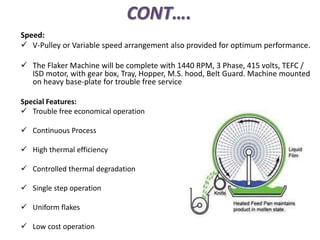

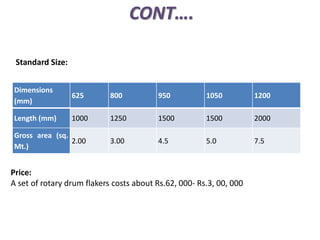

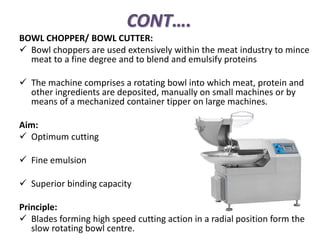

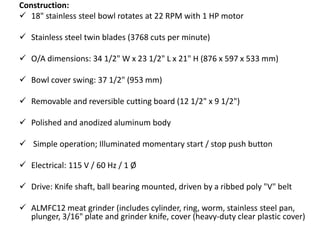

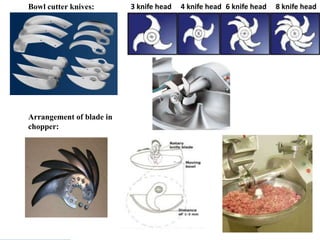

- Mincing, milling, flaking, chopping, curing, tumbling, massaging, and smoking meat are some of the main processes discussed. Specific equipment like mincers, mills, flakers, and bowl choppers are explained.

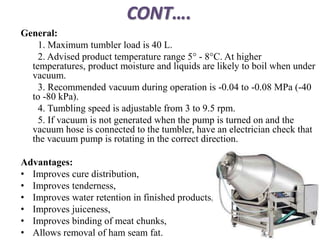

- Curing meat involves salting it with sodium chloride and sodium nitrite to produce the characteristic pink or red color when cooked. Tumbling helps cure penetration by increasing temperature and disrupting muscle tissue.

- Smoking meat uses wood smoke to preserve meat and impart flavor through compounds like phenols, aldehydes, and acids while also coloring the meat surface. Cold and hot smoking