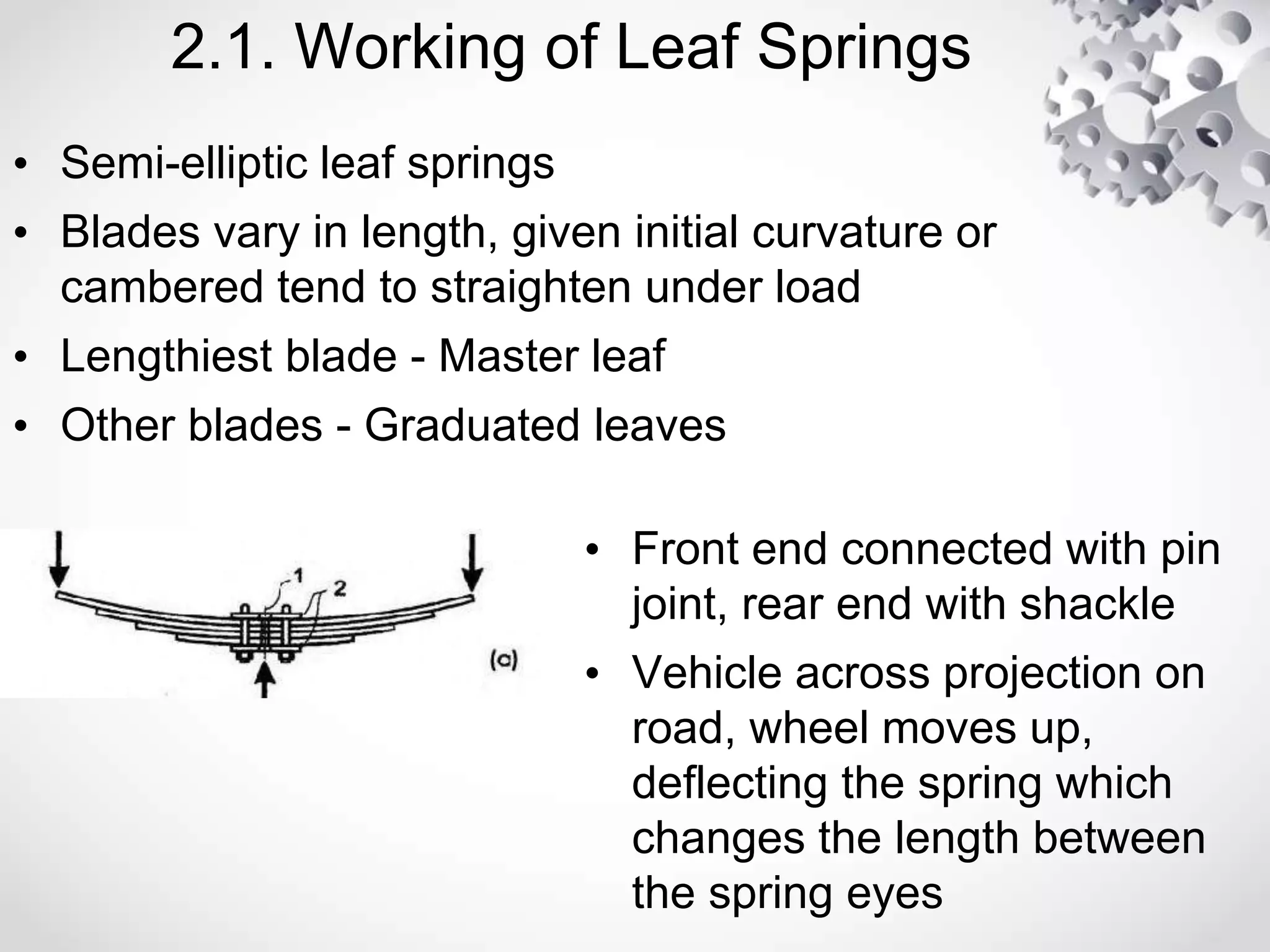

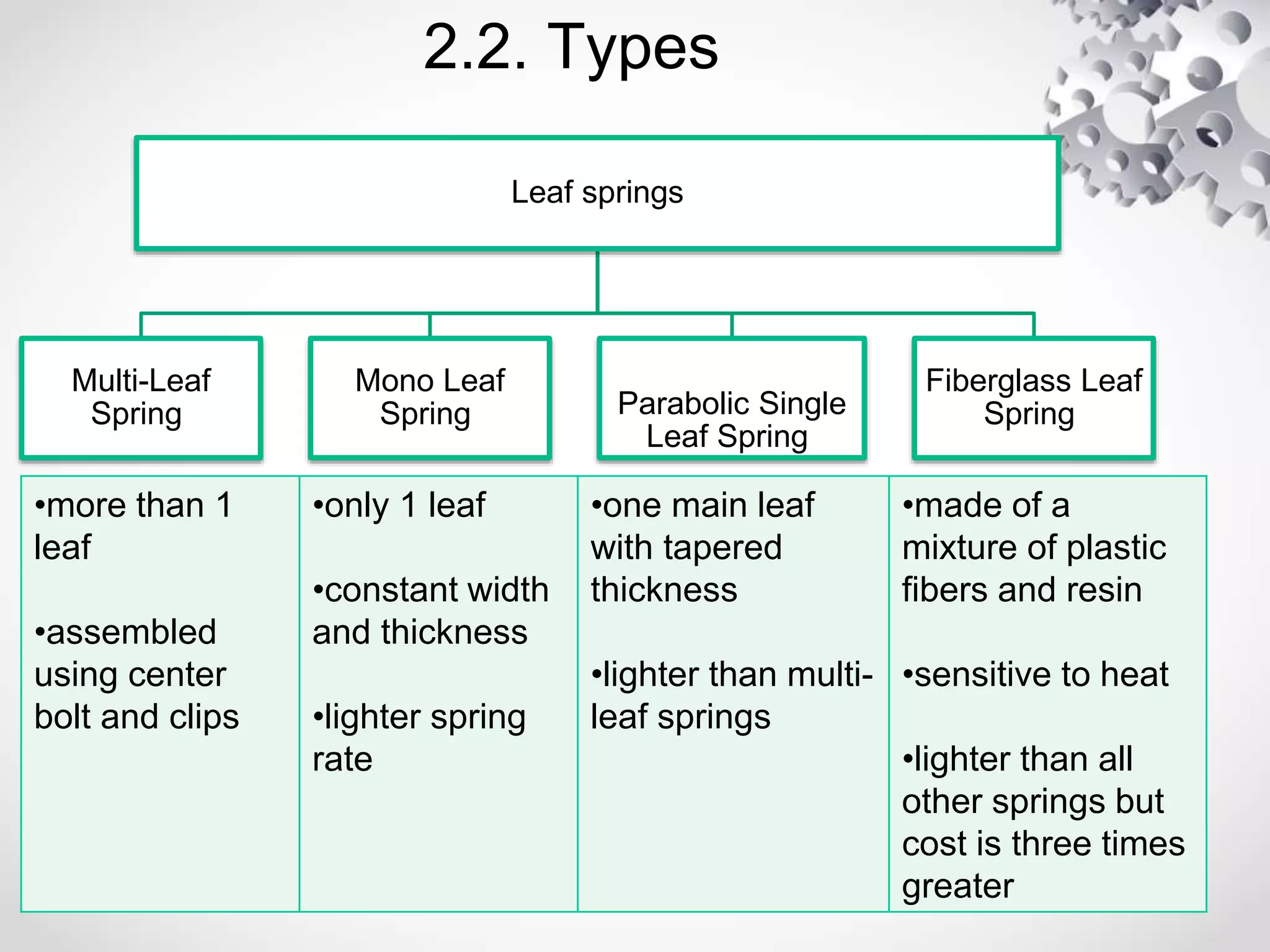

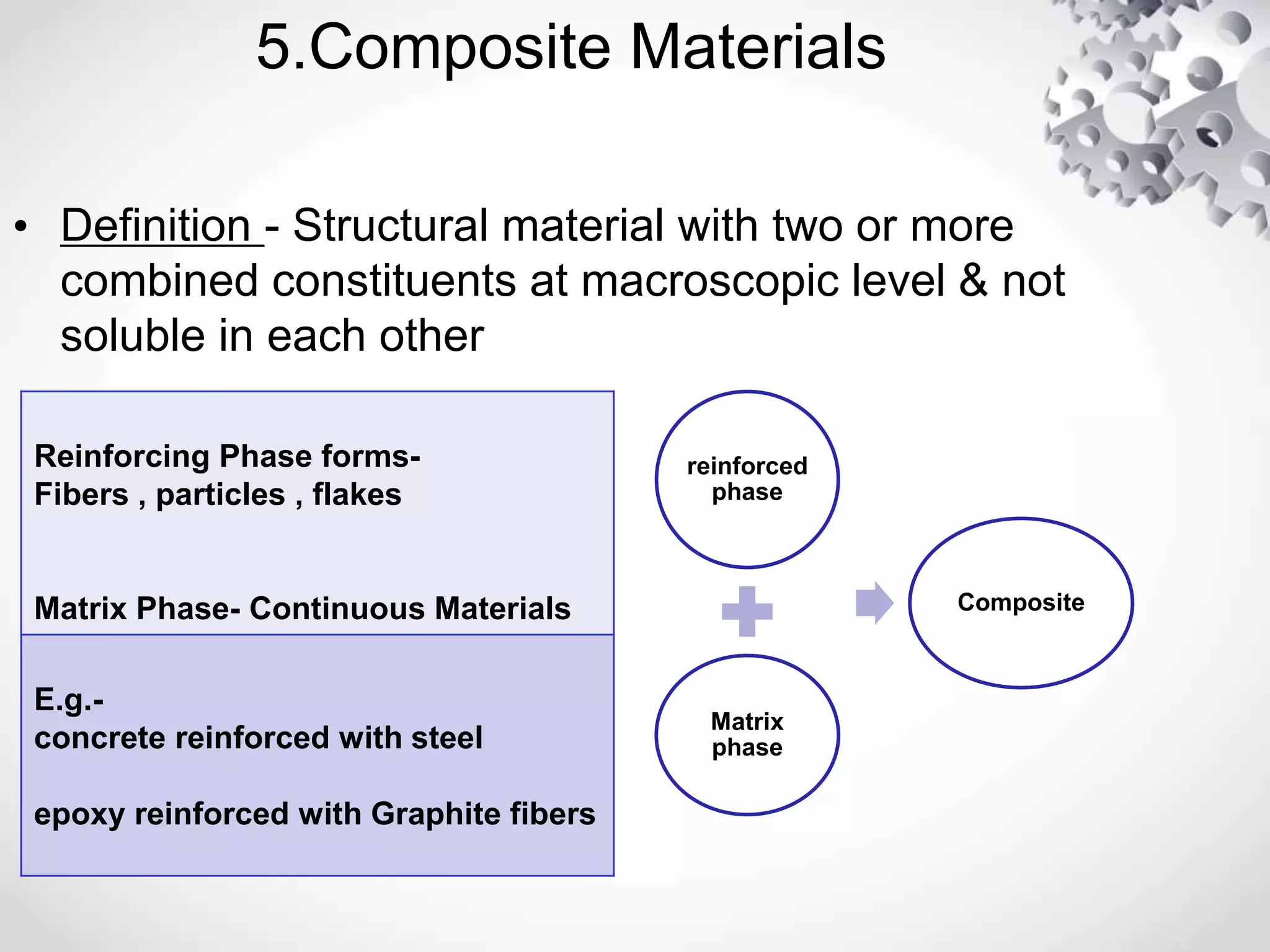

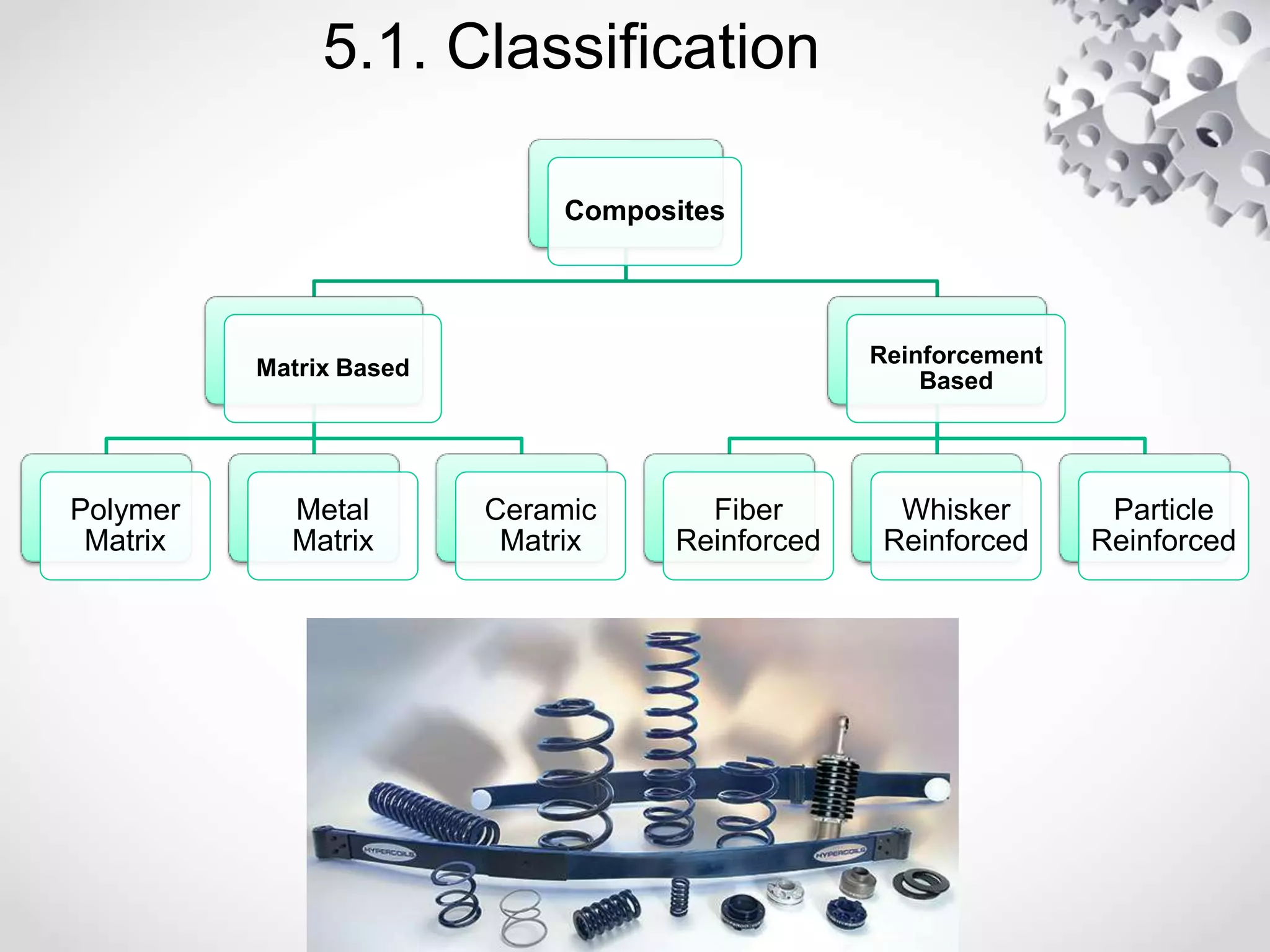

This document discusses the fabrication of composite leaf springs for vehicle suspension systems. It aims to reduce vehicle weight through the use of composite materials like glass fiber reinforced plastic (GFRP) instead of conventional steel springs. The document outlines the manufacturing process of composite leaf springs using hand lay-up techniques with GFRP and epoxy. It also summarizes the advantages of composite leaf springs like reduced weight and corrosion resistance compared to steel, though their production cost is currently higher. Experimental testing showed composite leaf springs have lower deflection and bending stress than steel springs under the same loads.