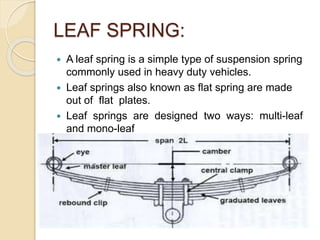

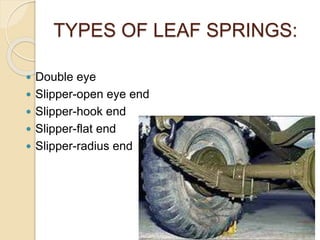

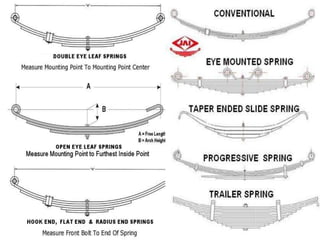

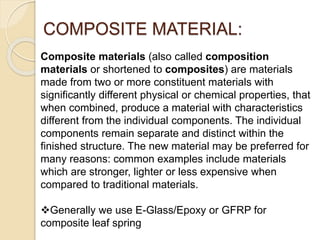

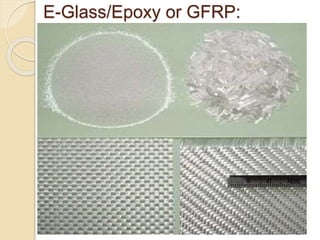

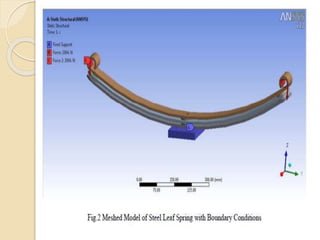

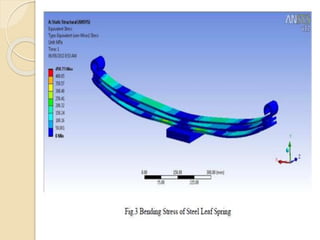

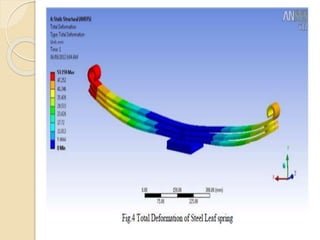

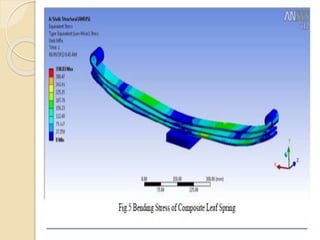

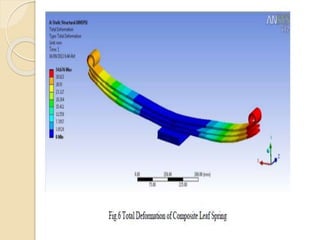

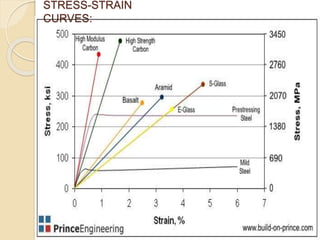

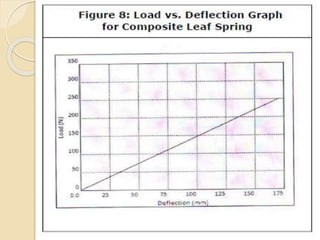

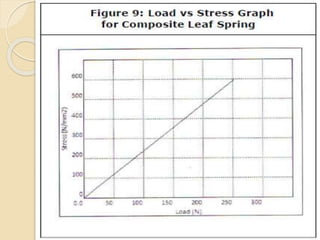

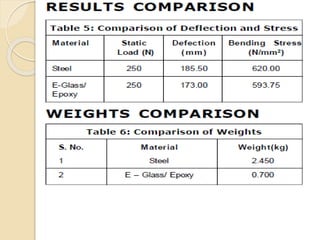

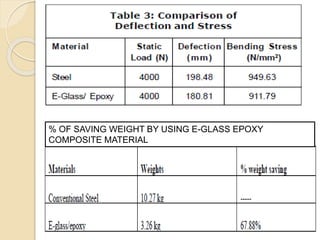

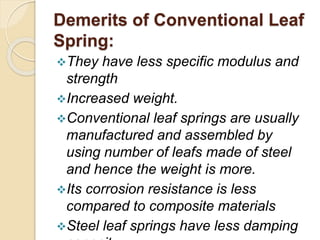

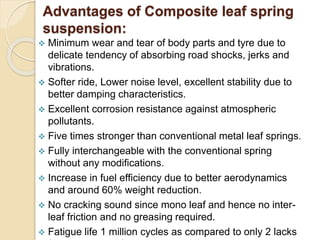

This document discusses replacing traditional leaf springs in vehicles with composite leaf springs made of fiberglass-reinforced plastic. It begins by introducing composite materials and their benefits of lighter weight, stiffness, and corrosion resistance. Leaf springs are then described as flat plates commonly used in heavy vehicles for suspension. Analysis was performed in ANSYS to compare the stress, strain, bending stress, and deformation of traditional steel leaf springs and composite leaf springs under different loads. The results show the composite leaf springs can reduce weight by around 60% while increasing fatigue life and providing benefits like better damping and corrosion resistance over steel springs.