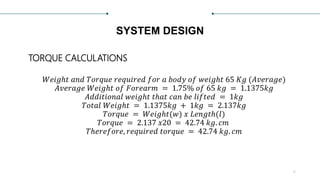

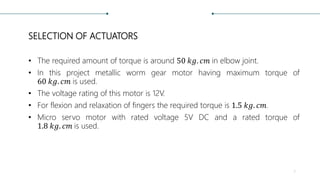

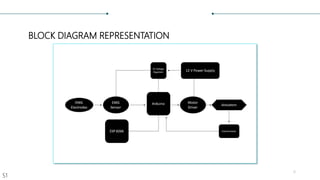

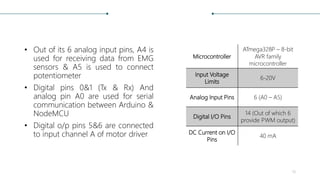

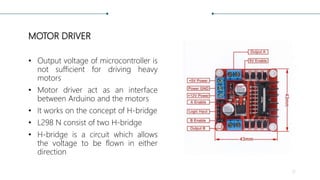

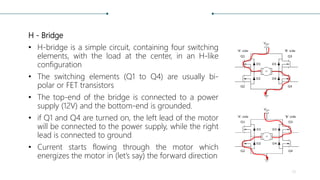

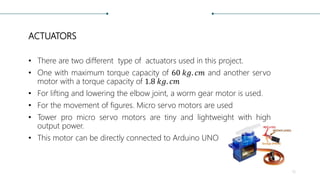

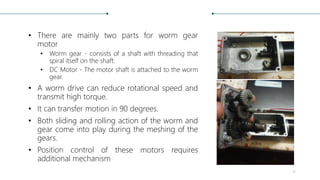

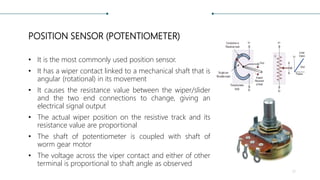

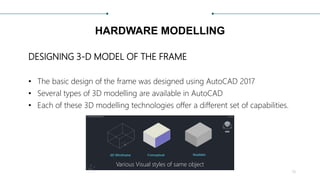

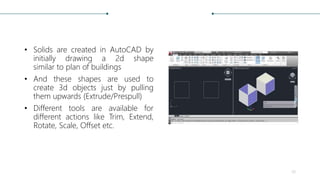

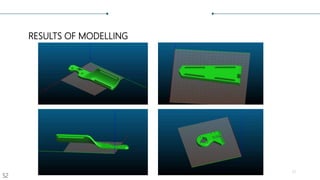

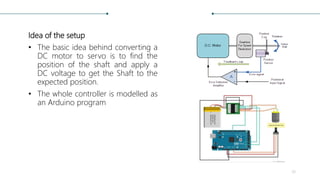

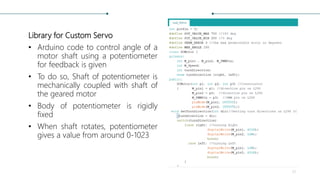

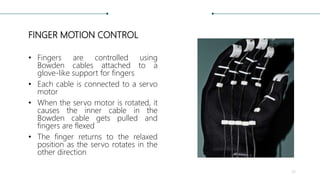

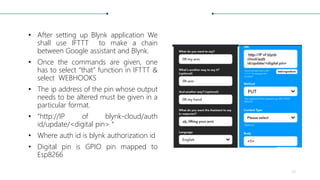

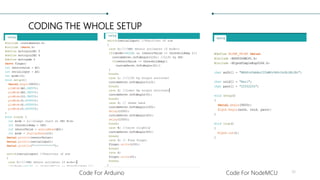

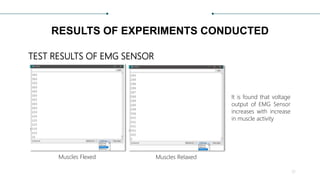

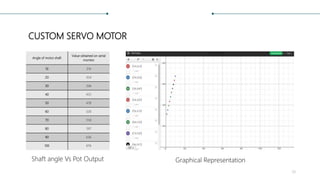

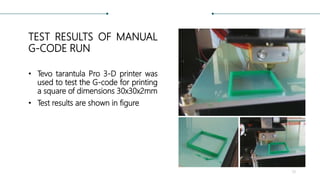

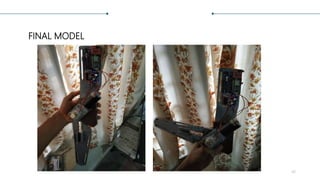

The Exoskeleton Arm Project Phase II aims to develop a hand exoskeleton for stroke rehabilitation, leveraging IoT to enable remote monitoring and therapy. The design involves multiple components, including actuators, microcontrollers, and EMG sensors, with a focus on torque requirements and a 3D-printed frame for the arm. The system integrates voice command functionality through Google Assistant and has potential applications in medical rehabilitation as well as military use.

![EXOSKELETON ARM

Project Phase II

› PROJECT GUIDE

› Mr. Anuroop PV

› Assistant Professor

› Division of EEE

› GROUP MEMBERS

› Adheena Joseph [19170200]

› Akarsh B Dhanesh [19170204]

› Anagha Chand P [19170207]

› Vivek C [19170240]

1](https://image.slidesharecdn.com/exoskeletonarmppt-201116160828/75/Exoskeleton-arm-ppt-1-2048.jpg)