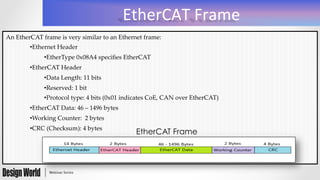

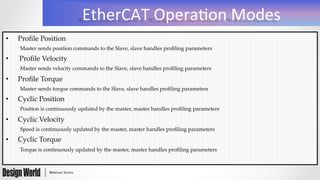

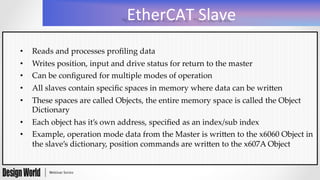

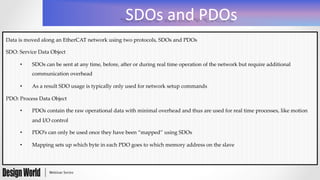

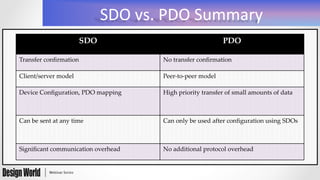

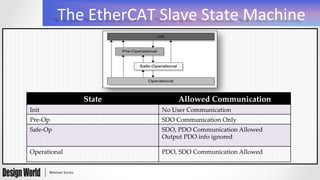

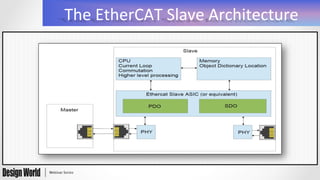

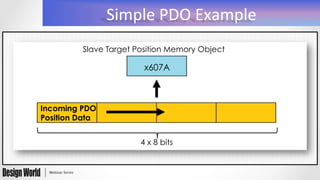

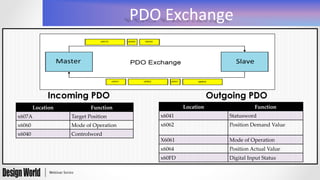

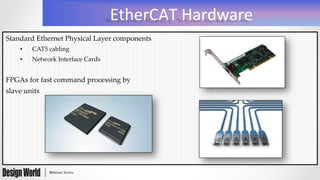

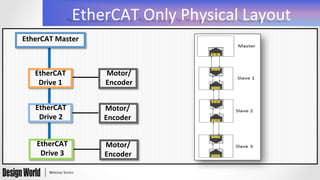

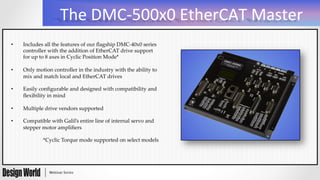

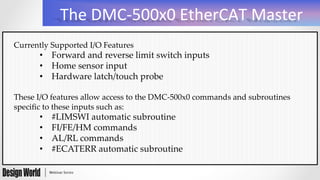

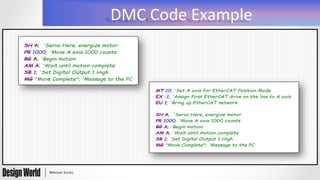

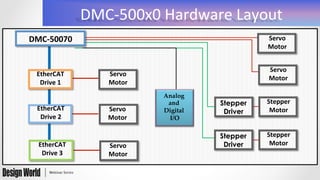

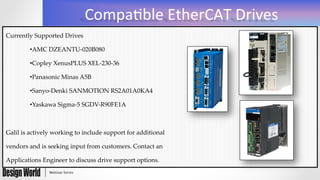

This document provides an overview of EtherCAT, a protocol developed for industrial automation, highlighting its efficient communication capabilities and advantages over standard Ethernet. It introduces the DMC-500X0 EtherCAT master controller by Galil, which supports up to eight axes in cyclic position mode and is designed for compatibility with various drive vendors. The presentation outlines the architecture, operation modes, and communication protocols (SDOs and PDOs) involved in implementing EtherCAT in motion control applications.