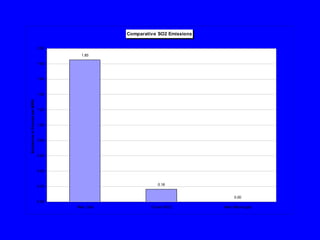

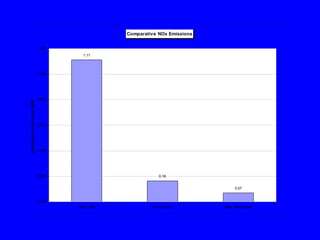

Integrated coal gasification combined cycle (IGCC) power plants convert coal into synthetic gas for cleaner electricity generation compared to conventional plants, leading to reduced air pollutant emissions. IGCC technology enables efficient mercury capture and lower CO2 emissions, making it a significant option for advancing both carbon capture and the potential production of hydrogen fuels. The transition to IGCC systems is pivotal for enhancing the economic viability of various coal-derived products and advancing carbon sequestration techniques.