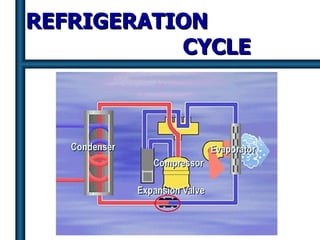

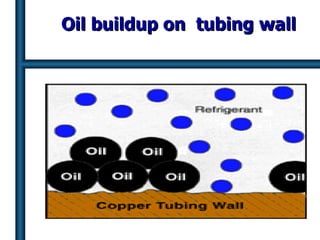

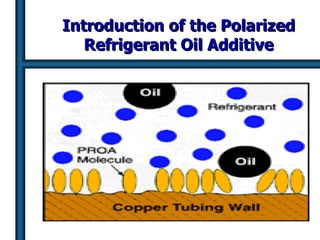

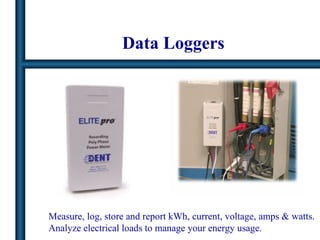

Reverse Technologies is a company based in San Jose, CA that was established to promote energy conservation. One of their energy conservation efforts is a patented Polarized Refrigerant Oil Additive called Compress Shield, which has been found to be highly effective by the U.S. Department of Energy. Compress Shield helps reduce operating costs by an average of 5% guaranteed, reduces maintenance costs, and extends equipment life by improving heat exchange and reducing friction in HVAC systems. Reverse Technologies performs inspections, establishes energy usage baselines, installs Compress Shield, and documents the energy savings achieved. The cost of applying Compress Shield typically pays for itself within 18 to 24 months through reduced energy costs.