This document provides instructions for 9 experiments in engineering mechanics:

1. Verifying the parallelogram law of forces using Gravesand's apparatus.

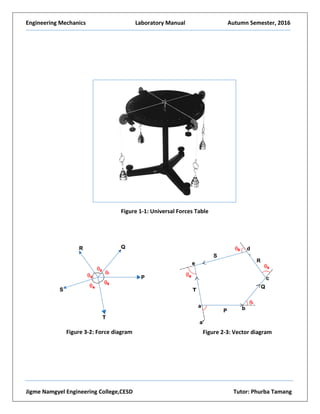

2. Verifying the triangle law of forces using a universal force table.

3. Verifying the polygon law of forces using a universal force table.

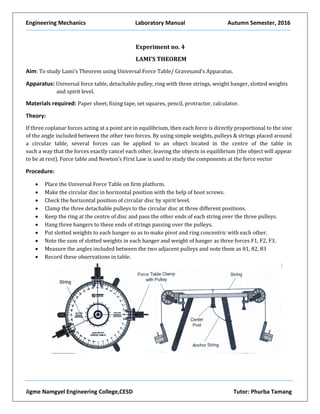

4. Studying Lami's theorem using a universal force table or Gravesand's apparatus.

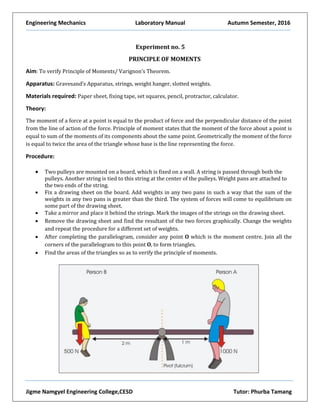

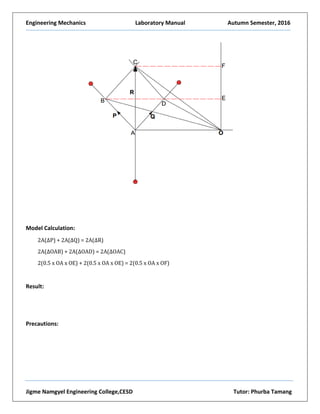

5. Verifying the principle of moments.

6. Studying coefficients of sliding and rolling friction.

7. Studying a worm and worm wheel.

8. Studying a double purchase winch crab.

9. Studying a differential wheel and axle.

The document provides the