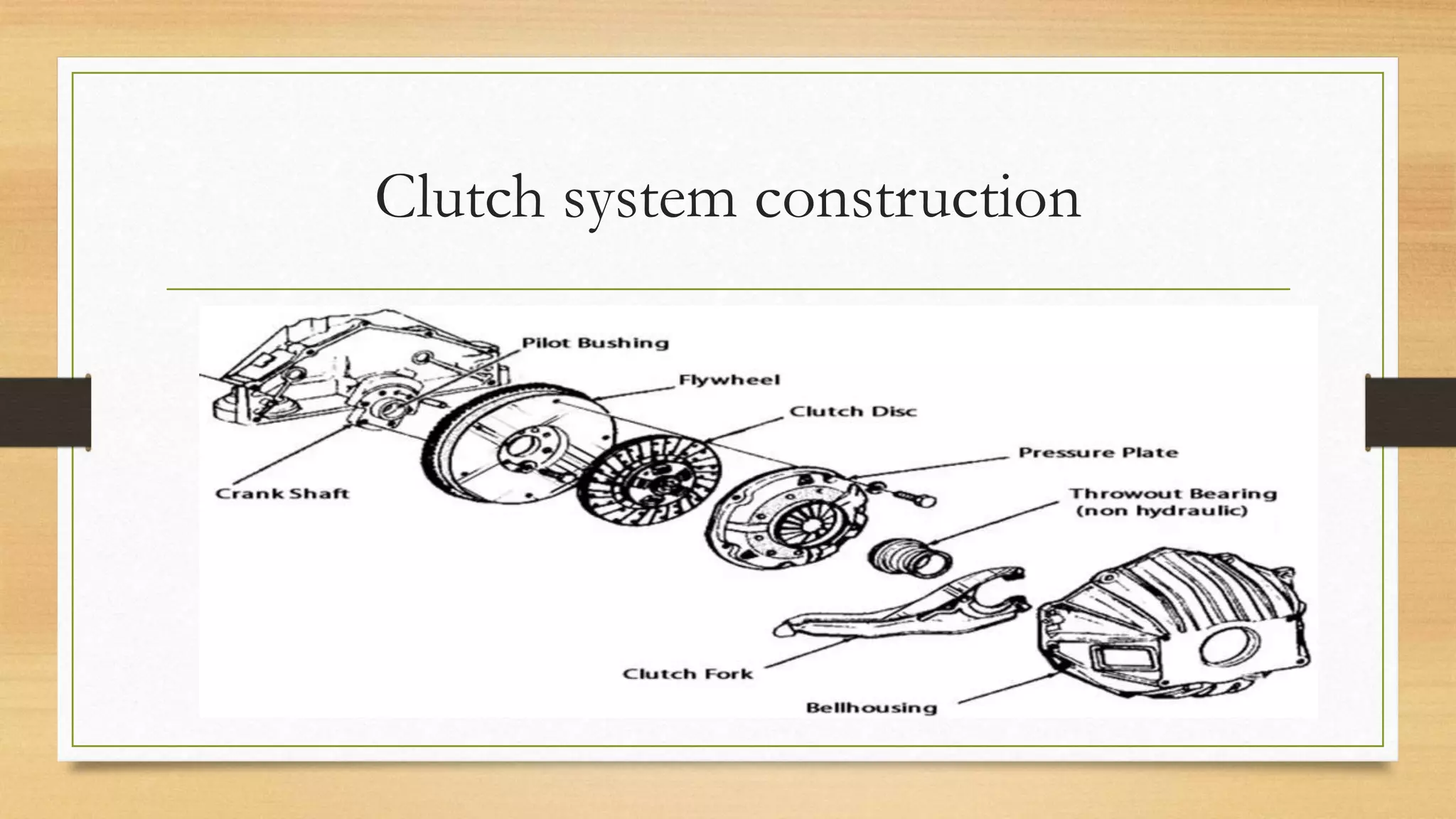

The document summarizes the operation and construction of automotive clutches. It describes how clutches engage and disengage the transmission from the engine to allow gear changes. There are two main types - manual clutches controlled by a foot pedal and automatic clutches using clutch packs. A typical clutch consists of a flywheel, friction disc, and pressure plate. The flywheel smooths power delivery and the disc engages and disengages via a pressure plate to select gears and start the vehicle.