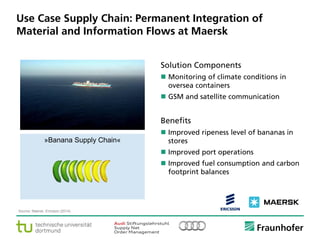

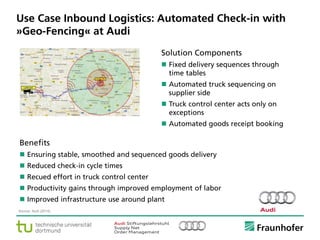

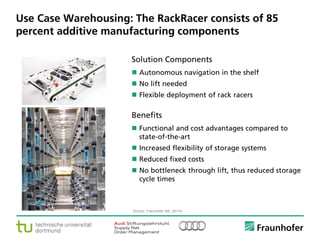

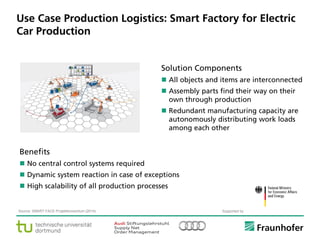

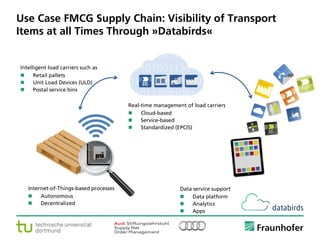

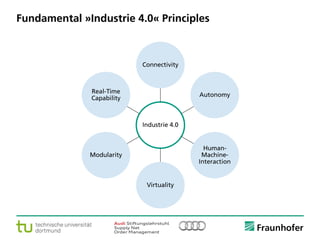

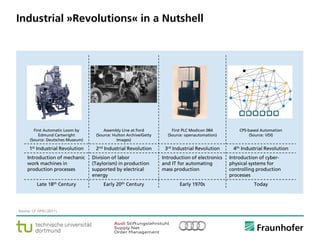

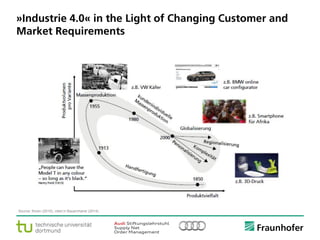

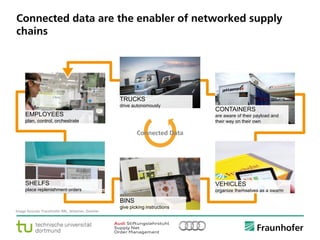

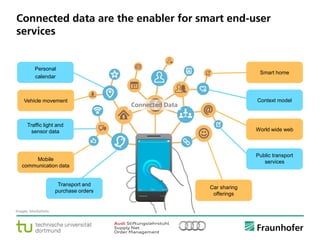

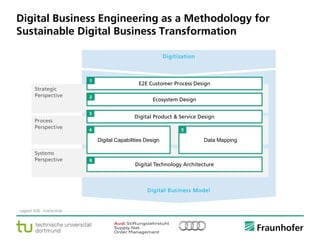

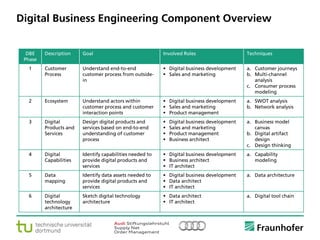

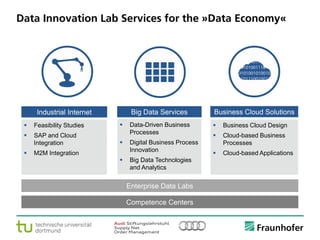

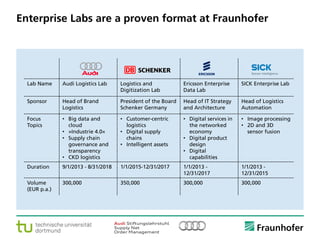

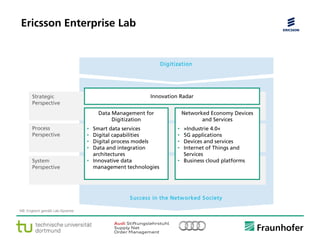

The document presents various use cases for industrial data management and digitization, highlighting implementations across supply chains, logistics, and production processes. Noteworthy examples include the integration of monitoring systems for climate conditions in supply chains, automated logistics solutions at Audi, and smart factory concepts for electric vehicle production. It underscores the principles of 'Industrie 4.0' such as connectivity, autonomy, and real-time capabilities, aiming for optimized efficiency through technology and data-driven strategies.