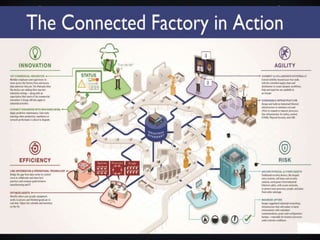

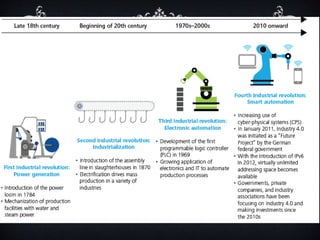

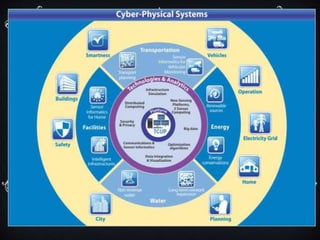

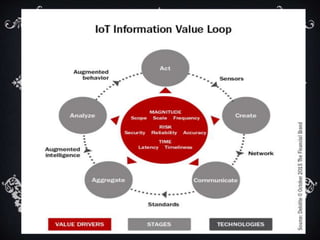

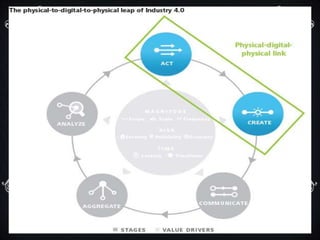

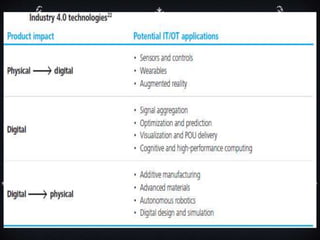

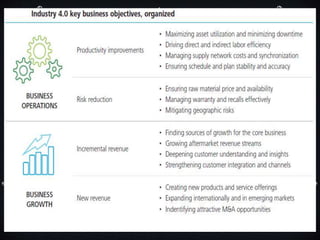

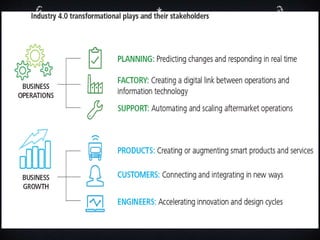

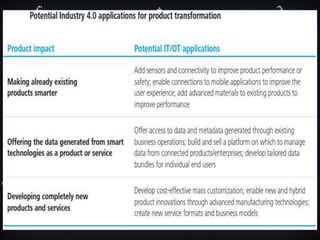

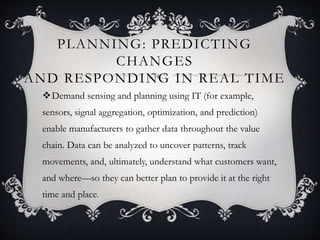

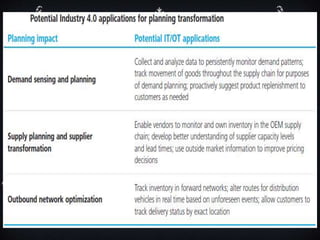

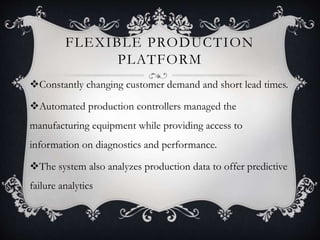

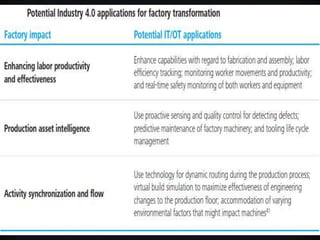

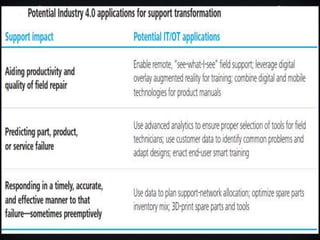

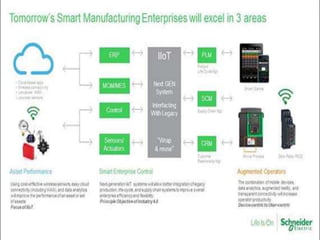

The document discusses Industry 4.0 as a transformative movement in manufacturing, characterized by the integration of digital and physical systems through advanced technologies like IoT, AI, and Additive Manufacturing. It highlights that manufacturers must adapt to evolving connectivity and data analytics to increase productivity, reduce risks, and create new revenue opportunities. Challenges such as talent shortages, standards for interoperability, and data ownership are emphasized as critical considerations for successful implementation.