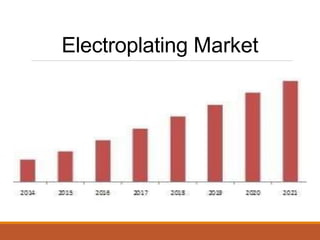

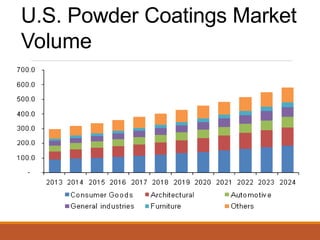

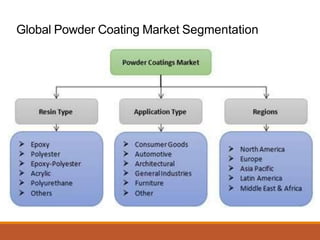

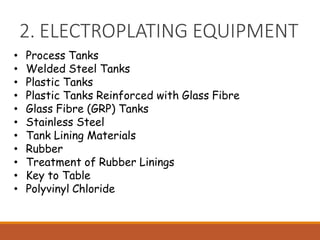

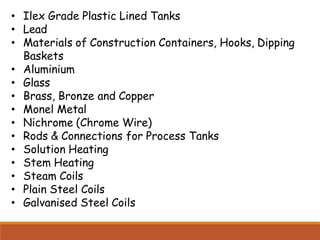

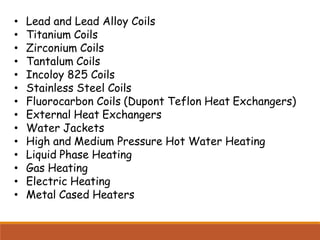

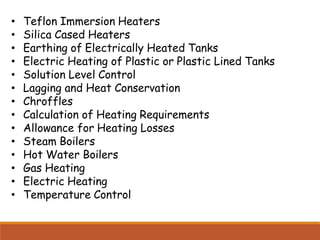

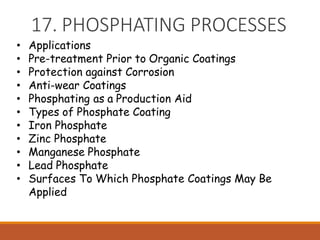

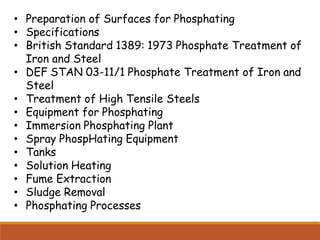

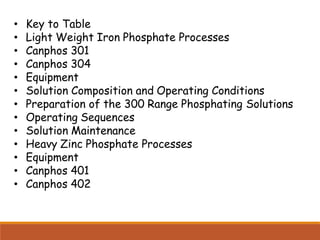

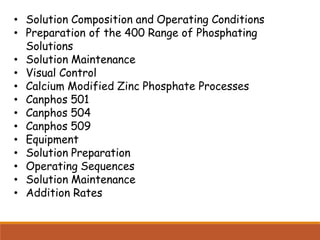

The document discusses various metal finishing processes including electroplating, phosphating, powder coating and their applications. It provides details on electroplating equipment and processes, cleaning and pretreatment methods before electroplating, and the electrical equipment used. It also discusses powder coating and describes the global market outlook for electroplating, phosphating and powder coatings.