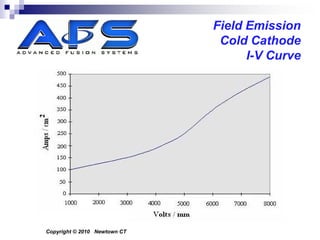

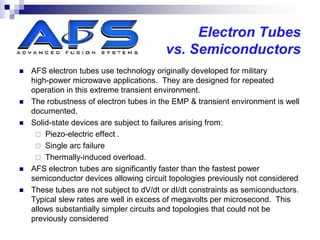

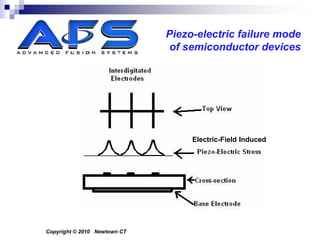

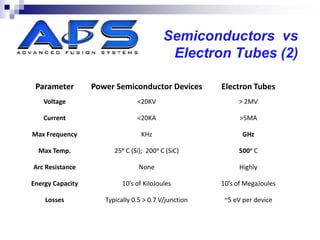

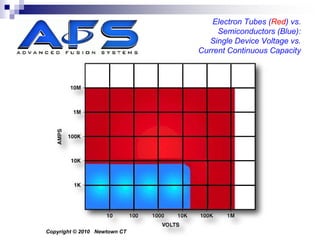

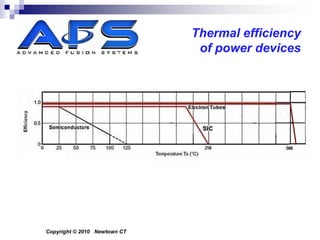

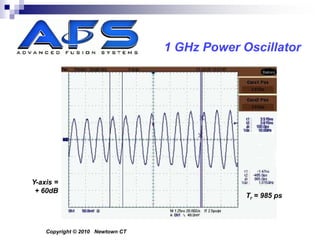

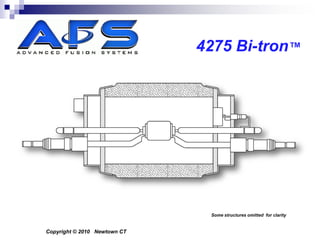

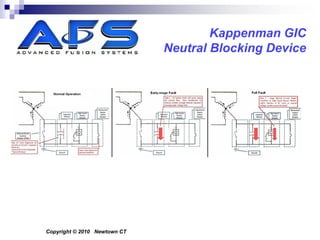

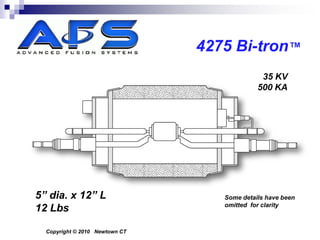

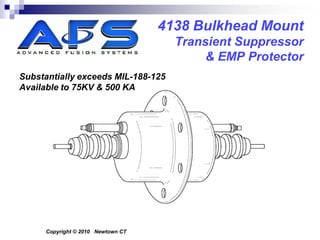

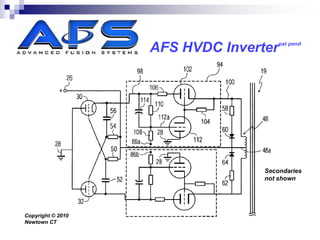

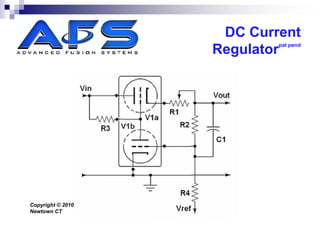

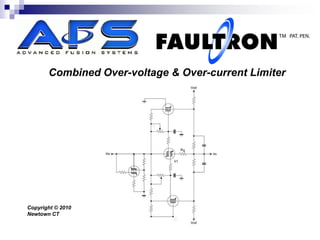

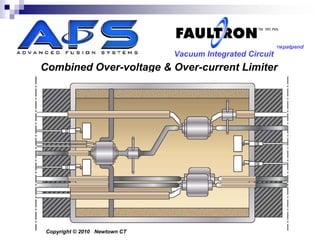

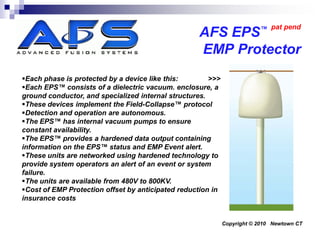

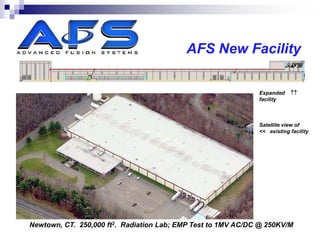

Advanced Fusion Systems LLC is developing high-power cold cathode electron tubes aimed at replacing semiconductor devices in power electronics applications due to their limitations. The company is constructing a manufacturing facility and plans to offer products including EMP and GIC protective devices, inverters, and various fault limiters, leveraging the high performance and reliability of their electron tube technology. Their products feature high voltage and current handling capabilities, minimal cooling requirements, and robust performance in extreme conditions.