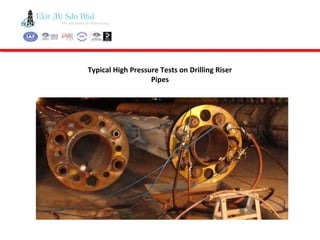

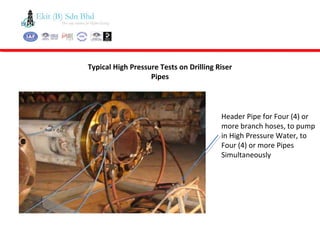

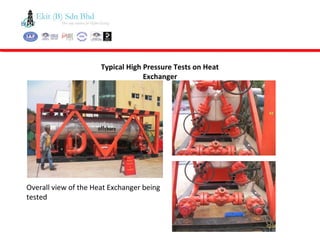

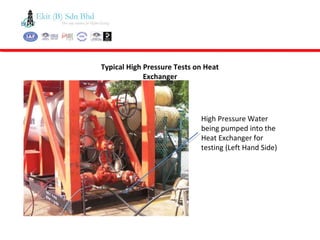

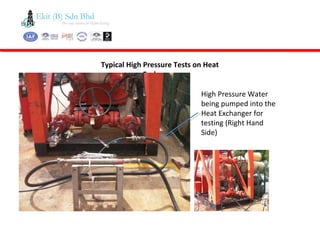

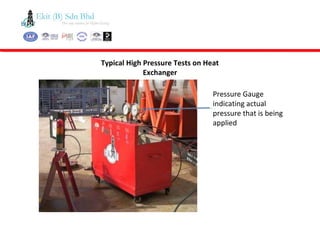

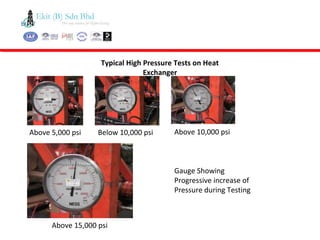

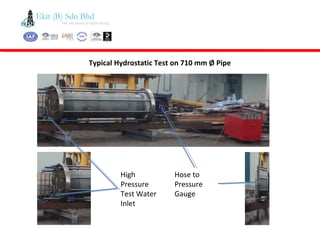

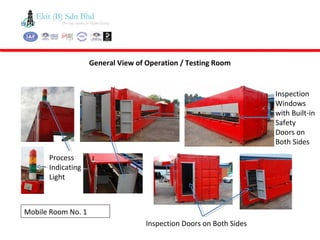

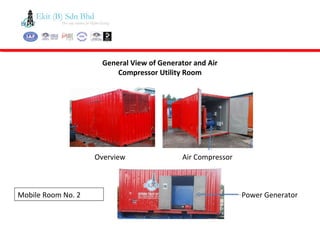

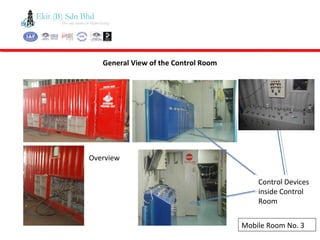

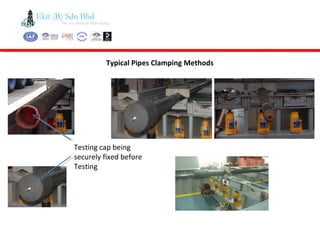

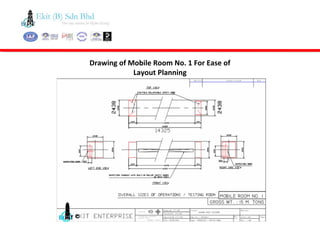

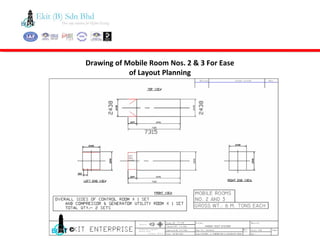

Ekit (B) Sdn Bhd, established in Brunei Darussalam, specializes in hydro-testing services for the oil and gas industry using a unique mobile hydrostatic testing system. The company offers comprehensive pressure testing solutions for various types of piping and equipment, ensuring quality and safety with trained operators. They provide competitive pricing and can deploy their services in offshore and field locations.