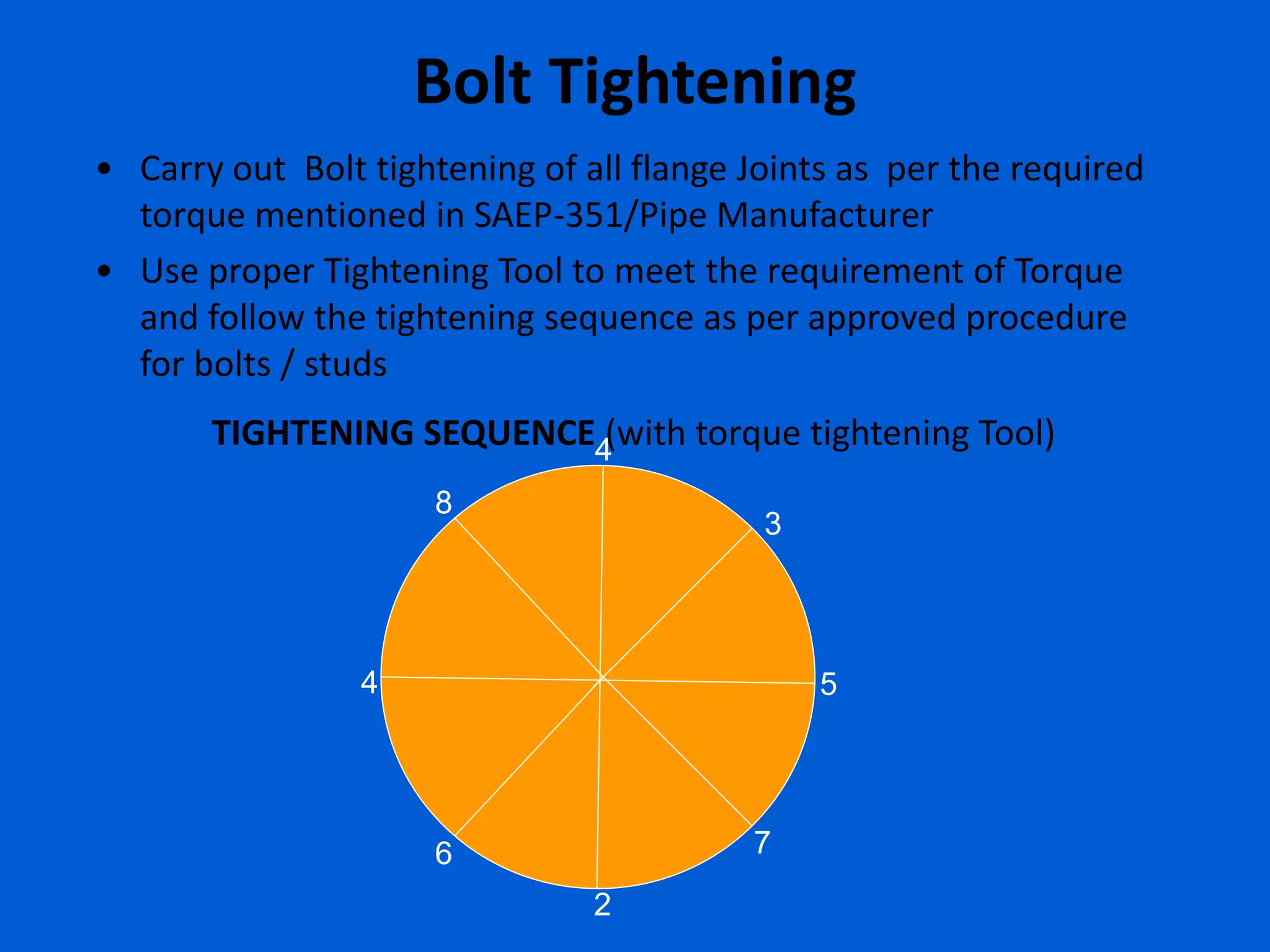

The document outlines the procedures and requirements for conducting hydrostatic tests on piping systems, emphasizing the importance of pressure testing to ensure integrity and safety. It discusses types of tests, prerequisites like calibration of equipment, and steps for executing and monitoring the hydrotest. The hydrotest package is detailed, listing essential documentation and checks required for compliance with engineering standards.