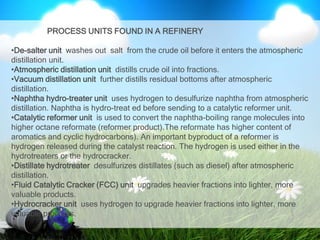

The document discusses industrial wastewater treatment at an oil refinery. It provides an overview of the oil refining process and the various units involved. Significant waste is produced, including hazardous materials in wastewater. Refinery wastewater treatment typically involves oil removal through API separation and dissolved air flotation, followed by equalization and biological treatment using activated sludge. Additional steps like nitrification and denitrification may be used to meet strict nitrogen limits. Proper wastewater treatment is important to meet environmental standards and protect public health from potential health hazards of untreated effluent.

![Reference

Gary, James H., Glenn E. Handwerk, and Mark J. Kaiser.

Petroleum refining: technology and economics. CRC press,

2007.

• Leffler, William L. "Petroleum refining for the nontechnical

person." (1985).

• The Environment (Protection) Rule, 1986 are referred to as

principal rules in all subsequent Notifications beginning with

S.O. 32(E), dated 16.2.1987 published in the Gazette No.

66, dated 16.2.1987

.

• EPA Notification [G.S.R 186(E), dt. 18th March, 2008]](https://image.slidesharecdn.com/oilandgasrefineryppt-230404173318-2cbd73fe/85/Oil_and_gas_Refinery_ppt-ppt-21-320.jpg)