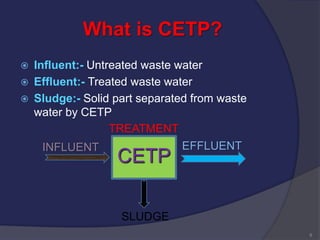

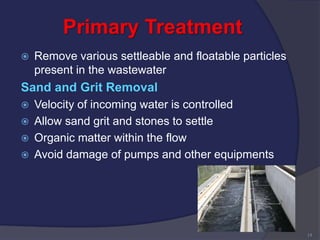

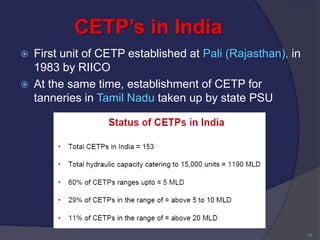

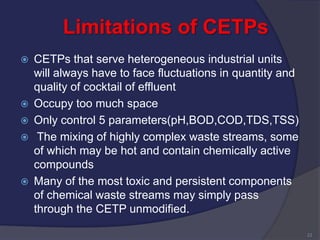

The document discusses global water scarcity and the significance of wastewater treatment plants (WWTP) in addressing this issue. It explains different types of treatment plants, management principles for Common Effluent Treatment Plants (CETP), and the stages involved in wastewater treatment. The advantages and limitations of CETPs are also highlighted, emphasizing their role in assisting small and medium industries while addressing the challenges posed by varying effluent qualities.