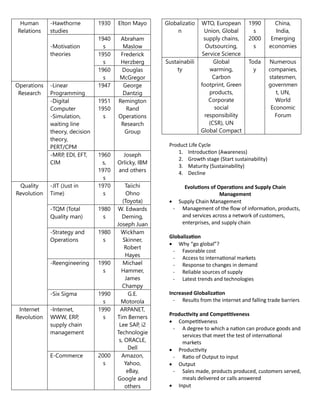

This document serves as an introduction to operations and supply chain management, outlining the fundamentals of operations management, transformation processes, and the importance of quality management. It discusses historical advancements in operations, strategic positioning, and the relationship between operations and various business functions like marketing and finance. Key concepts such as the value chain, productivity, and quality management principles, including Six Sigma and TQM, are emphasized for improving organizational efficiency and effectiveness.