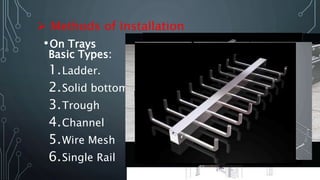

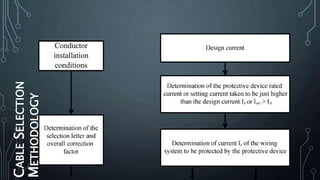

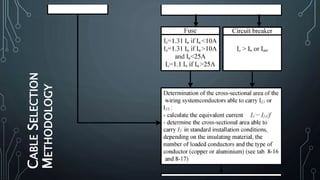

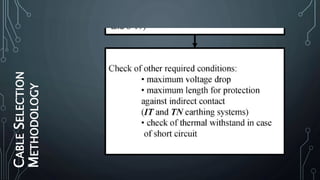

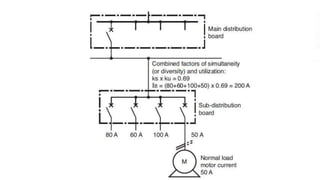

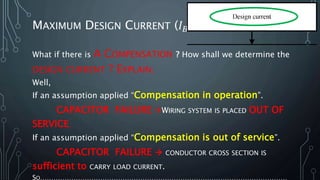

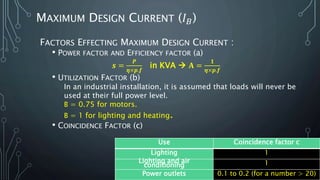

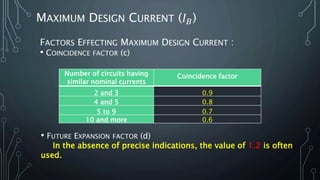

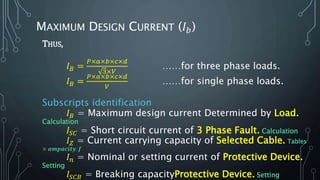

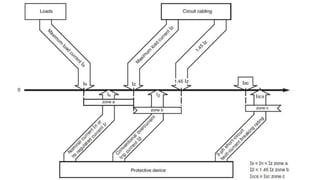

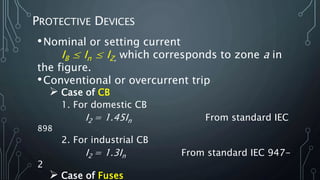

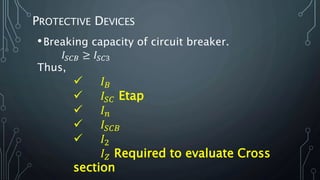

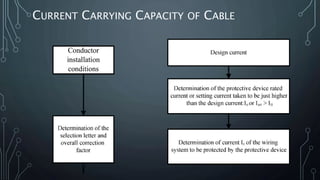

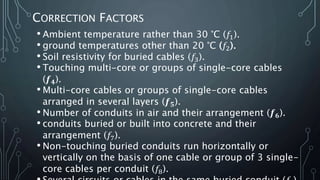

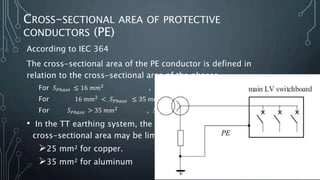

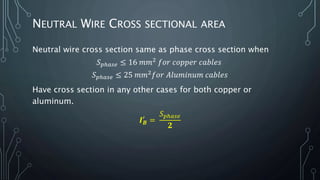

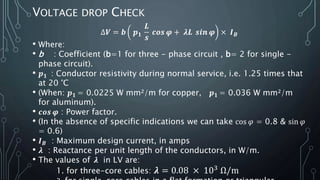

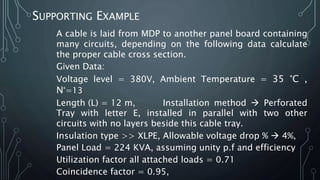

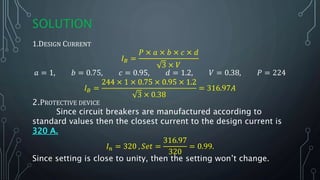

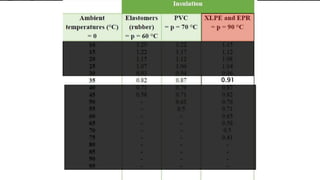

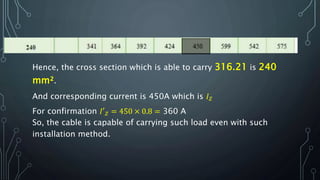

The document outlines the methodology for selecting power cables, emphasizing important properties such as flexibility, load capacity, and safety. It details specifications regarding voltage classes, insulation types, installation methods, and design calculations including maximum design current and voltage drop considerations. A supporting example is provided, demonstrating calculations to determine appropriate cable cross-section based on various factors including ambient temperature and installation conditions.