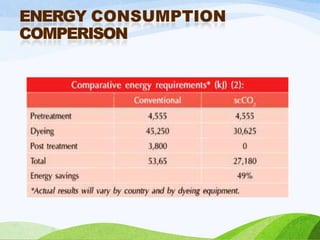

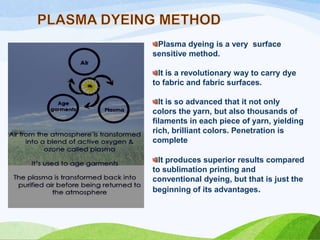

This document discusses several innovative textile dyeing technologies that reduce environmental impact compared to traditional water-based dyeing. It describes processes such as dyeing with supercritical CO2, plasma dyeing, sublimation and transfer printing, and foam dyeing. Plasma dyeing allows for deep penetration and rich colors. Technologies like nano-dyeing and biomimicry of structures in butterfly wings could eliminate use of dyes and chemicals. Overall, the document introduces more sustainable dyeing alternatives that consume less water, energy and chemicals.