Industrial attachment of knit concern limited (kcl)

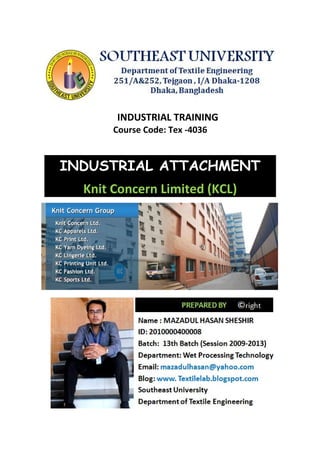

- 1. INDUSTRIAL TRAINING Course Code: Tex -4036 INDUSTRIAL ATTACHMENT Knit Concern Limited (KCL)

- 2. Name ID Md. Rasel Rabby 2008000400067 Md. Farid-ul-Islam 2008000400066 Md. Masud Rana 2008000400054 Md. Subuj Mia 2008000400005 Brief Presentation Industrial Attachment Industry Name: Knit Concern Limited (KCL) School: Science and Engineering Course of Studies: B.Sc. in Textile Engineering Supervising Teacher: Prof. Syed Fakhrul Hassan Chairman Department of Textile engineering. Southeast University Submitted By, Batch 7th January, 2012

- 3. iii Abstract Textile technology education is based on industrial ground. Theoretical background is not sufficient so, industrial training is an essential part of study to make a technologist techni-cally sound in this field. Industrial training provides us that opportunity to gather practical knowledge. Knit Concern Limited (KCL) is a truly integrated undertaking. The textile division has the capability to offer a complete product range for the export & domestic textile ma r- kets. The goal of this textile factory is to become the preferred partner for sourcing high quality fabrics & clothing from Bangladesh. With high advanced technology & an empha- sis on developing local human resources, the textile division has the potential to make an important contribution to the nation’s growing readymade garments export sector. The rationale behind the existing structure & future expansion of the textile division is to capture value added at each stage of the textile manufacturing process. Despite Bangla- desh’s lack of indigenous cotton production capability Knit Concern Limited (KCL) has leveraged Bangladesh’s labor cost advantage & export competitiveness to maximum level.

- 4. iv Acknowledgement All the praises are for the almighty, Allah who bestowed us with the ability and potential to complete this Internship. We also pay my gratitude to the Al-mighty for enabling us to complete this Internship Report within due course of time. Project paper is an academic function of the Southeast University. We are highly delighted to express our regards & gratitude to honorable Professor supervising teacher Prof. Syed Fakhrul Hassan for providing us the chance to complete our internship and completion our project work in KCL. Cordial thanks goes to Md. Touhidul Islam Kakon,Sr. Manager of KCL for their excellent co-operation during the period of our training. We also take the opportunity to express our sincerest gratitude to the management, administration & personnel of KCL for their kind assistance. Above all, we would like to acknowledge our deep debt to all teachers of our university & particularly of Wet Processing Department for their kind inspiration & help, which remain as the backdrop of all our efforts. Finally, we would like to acknowledge that we remain responsible for the in- adequacies & errors, which doubtless remain in the following report.

- 5. v Table of contents CHAPTER – 1................................................................................................................. 1 CHAPTER – 2................................................................................................................. 8 CHAPTER – 3............................................................................................................... 18 CHAPTER – 4............................................................................................................. 145 CHAPTER – 5............................................................................................................. 159 CHAPTER – 6............................................................................................................. 174 CHAPTER – 7............................................................................................................. 191 CHAPTER – 8............................................................................................................. 208 CHAPTER – 9............................................................................................................. 212 CHAPTER – 10............................................................................................................ 216 CHAPTER – 11............................................................................................................ 218 CHAPTER – 12............................................................................................................ 221

- 6. Industrial Attachment Page 1 of 229 CHAPTER – 1 PROJECT DESCRIPTION

- 7. Industrial Attachment Page 2 of 229 NAME : Knit Concern Limited (KCL) TYPE : 100 % Export Oriented Knit Composite Industry SISTER CONCERN : KC Apparels Ltd. KC Sports Ltd. KC Lingerie Ltd. KC Printing Ltd. KC Yarn Dyeing Ltd. YEAR OF ESTABLISHMENT : 1990 ADDRESS : 62, Water Works Road, Godnail Narayangonj-1400, Bangladesh

- 8. Industrial Attachment Page 3 of 229 LOCATION 62, Water Works Road, Godnail, Narayangonj-1400, Bangladesh Phone : 88-02-7641086 : 88-02-7641088 : 88-02-7646869 Fax : 88-02-7641087 E-mail : info@knitconcern.com Web : www.knitconcern.com

- 9. Industrial Attachment Page 4 of 229 Washingunit Residentialarea OVERALL LAYOUT PLAN OF THE PROJECT Knitting Unit Medical center Storage (Grey fabric) Storage (Grey fabric) WTP KCL + KCAL Generator Sp. Finishing Generator KC Yarn dyeing Ltd KC Lingerie Ltd. WTP Main Storage Unit ETP Residential area

- 10. Industrial Attachment Page 5 of 229 ACHIEVEMENTS ISO 9001:2008(Certified) Oeko-Tex Standard 100 (Certified) May Day Award 2010 Premium Quality Supplier by JULES CSR awards PRODUCT MIX - 100 % cotton - CVC - Grey mellange - Ecro mellange - PC PROJECT COST 450 core Taka HISTORY OF PROJECT DEVELOPMENT KCL launched its very humble journey in 1990 from a rented building at Nayamati. That potential embryo by virtue of futuristic enterprising, dedication to quality, com- mitment to excellence, adoption of state of the art technology and keen focus on cus- tomer’s satisfaction, it could very rapidly metamorphose into a large corporate entity, in its most modern sense, just by 1998. Since its inception, Knit Concern has never stopped growing - in quality, quantity, and everything in between. Over the last couple of years, conceding to its growth requirement, using most contemporary ma- chines and equipment of German, Swiss, USA, Japan, Italy, China and UK origin, it has nearly doubled its capacity. At present, on a single campus at Godnail, Narajan- ganj, with all necessary integrations in all dimensions, Knit Concern is producing 1,20,000 pieces of very high quality garments per day. There are many indicators that may sketch the profile of Knit Concern ltd. business success but, perhaps, the in- crease of its export alone, from merely US$1.03 million in 1992 to about US$ 60 mil- lion in 2010, would show the degree of its exponential growth as a one-stop apparel

- 11. Industrial Attachment Page 6 of 229 supplier from Bangladesh. Now it becomes Knit Concern Group with several sister concerns. DIFFERENT DEPARTMENTS Production Oriented Departments: • Yarn store • Raw fabric store & Raw fabric inspection section • Knitting • Planning & Control • Batching Section • Chemical Store • Knit Dyeing Unit • Yarn Dyeing Unit • Tubular Finishing • Open Width Finishing • Special Finishing • Washing Unit • Garments Unit • Central Lab (Knit, Yarn, Wet & Physical) • Quality Control • Maintenance • Utility • Water Treatment Plant • Effluent Treatment Plant Supporting department: - Procurement - Merchandising - Research & Development - Marketing - IT - HRD - Finance & Accounting

- 12. Industrial Attachment Page 7 of 229 - Medical - Administration - Security REMARK Knit Concern Ltd. (KCL), the parent company of Knit Concern Group, started man- ufacturing and exporting knit garments back in the 1990s. Today, KCL and its subsid- iary, KC Apparels Ltd. (KCAL), both being fully composite units on a single campus, produce 1,20,000 pieces of knit apparels of latest quality and design everyday for the international markets. Knit Concern is one of the top corporate taxpayers in the in- dustry. It employs more than 8,500 people, and exports apparels worth over 60 mil- lion US dollars a year now. Besides, conforming to fair and eco-friendly standards, it contributes in terms of both wealth and welfare to the nation.

- 13. Industrial Attachment Page 8 of 229 CHAPTER – 2 MANPOWER MANAGEMENT

- 14. Industrial Attachment Page 9 of 229 MANAGEMENT SYSTEM: Intercom telephone Fax Written letters & Oral SHIFT CHANGE: There are two shifts in this industry. So the shifts arechanged at every12 hours. SHIFTING FOR WORKERS: Shift From To A 6 2 B 2 10 C 10 6 RESPONSIBILITIES OF PRODUCTION OFFICER: 1. Give dyeing program slip. 2. Match production sample with target shade. 3. Collect production sample lot sample matching next production, 4. Observe dyed fabric during finishing running & also after finish- ing. 5. Identity disputed fabrics & report to P.M/G.M. for necessary ac- tions. 6. Discuss with P.M about overall production if necessary. 7. Sign the store requisition & delivery challan in the absence of P.M. 8. Also to execute overall floor works. 9. Maintain loading'/unloading khata. 10. Any other assignment given by higher authority.

- 15. Industrial Attachment Page 10 of 229 JOB DESCRIPTION OF PR ODUCTION OFFICER: REPORT TO : Sr. Production officer. JOB SUMMARY: To plan, execute & follows up the production activities & control the quality produc- tion with related activities. DUTIES & RESPONSIBILITIES: Overall supervision of dyeing, finishing production. Batch preparation & pH I chock. Dyes & chemical requisition issue & check. Write Fabrics loading & unloading time from m/c Program making, sample checking, color measurement Control the supervisors, operator, assistant operator and helper of Dyeing m/c. Andalso anyother over workas & when required by the management. JOB DESCRIPTION OF SENIOR PRODUCTION OFFICER: REPORT TO : D.G.M. (production) JOB SUMMARY : To plan, execute & follows up the production activities & control the quality produc- tion with related activities. DUTIES & RESPONSIBILITIES: Overall supervision of dyeing, finishing production. Checks the sensitive parameters of different machine for smooth dyeing Checks the different log books of different areas & report to management Checks out the plan to control the best output from supervisors & workers. Trained up & motive the subordinates how to improve the quality produc- tion. Control the supervisor, operator, Asstt. Operator & helper of dyeing. Maintenance of machine & equipment Any other works & when required by the management

- 16. Industrial Attachment Page 11 of 229

- 17. Industrial Attachment Page 12 of 229

- 18. Industrial Attachment Page 13 of 229

- 19. Organogram of KCL(yarn dyeing unit) Managing Director Director AGM (Production) Sr. Manager (Maintenance) DPM Ass. Manager APM Engineer Sr. PO Ass. Engineer Incharge (QC) Incharge (Delivery) PO Incharge (Yarn Storage) Incharge (Chemical Store) Sub Ass. Engineer APO Foreman Sr. Supervisor Sr. Fitter man Supervisor Fitter man Ass. Supervisor Helper Sr. Operator Operator Ass. Operator Jr. Operator Helper Industrial Attachment Page 14 of 229

- 20. Industrial Attachment Page 15 of 229

- 21. Industrial Attachment Page 16 of 229 MAN POWER DISTRIBUTION KCL has a sufficient number of skilled manpower working in different sections. A view of manpower distribution with total manpower is given below: DEPARTMENT MANPOWER Knitting 656 Knit Dyeing 790 Yarn Dyeing 250 Washing 38 Finishing 315 Garments & printing 6133 Merchandising 42 Maintenance 105 Administration 45 Utility 40 Security 88 Total 8502

- 22. Industrial Attachment Page 17 of 229 REMARK The man power management system of Beximco Textiles Ltd. is well arranged. Every of- ficers & stuffs are responsible for their duty. The workers arc bounded to work for minimum 8 hours per day.

- 23. Industrial Attachment Page 18 of 229 CHAPTER – 3 MACHINE DESCRIPTION

- 24. Industrial Attachment Page 19 of 229 KNITTING Knitting Capacity: 35 Tons per day Total Machine: 128 Nos. Knit Concern's knitting facility is equipped with the world's latest and most dependable brand machinery like Fukuhara, Orizio and Stoll. Excellence in knitting, however, is an inborn characteristic of the group, inherited from the family of its chief, Joynal Abedin Mollah. This family has been in yarn trading and knitting since 1960s. In-Line inspec- tions, invariably followed by an intensive post-production inspection, are maintained throughout the entire knitting process. It produces numerous varieties of fabrics including Single Jersey, S/J Cotton Elastane, Rib, 1X1 Rib Cotton Elastane, Interlock, all kinds of Drop Rib, all kinds of PK, single Jersey and Double Jersey, Engineering Stripe, Thermal, Jersey Twill, Terry and many more. Figure: Single Jersey Knitting Machine (Fukuhara)

- 25. Industrial Attachment Page 20 of 229 MACHINE DETAILS TYPE BRAND MACHINE QUANTITY Single Jersey Orizio 03 nos. Single Jersey Fukuhara 32 nos. Single Jersey Lisky 04 nos. Single Jersey Open/Slitting Fukuhara 16 nos. Single Jersey Open/Slitting Mayer & Cie 10 nos. Rib / Interlock Fukuhara 20 nos. Interlock Fukuhara 08 nos. Interlock Lisky 01 nos. Rib Well Knitting 01 nos. Rib eyelet Jinhar 01 nos. Auto Striper (Four Color) S/J Fukuhara 04 nos. Auto Striper (Six Color) S/J Fukuhara 01 nos. Auto Striper (Four Color) Rib/Interlock Fukuhara 02 nos. Fleece 3 Thread Fukuhara 04 nos. Fleece 3 Thread Lisky 06 nos. Flat Knit Semi Jacquard Stoll 02 nos. Flat Knit Computerized Shima Seiki 05 nos. Flat Knit Computerized Matsuya 04 nos. Flat Knit Computerized Protti 04 nos Total 128 nos.

- 26. Industrial Attachment Page 21 of 229 KNIT DYEING KCL has dyeing and finishing facilities. It has the largest machinery for fabric dyeing and finishing. The state – of – the – art equipment reinforced with its intensive experience and expertise result in a clone – like uniformity of the dye house material. In dyeing section KCL uses Fong’s brand machines for high temperature and atmospheric dyeing. In fi- nishing section KCL is using the world’s latest technology of well – known brand Tube – Tex machine from USA and Santex brand from Switzerland. It has the both facilities the open width and tubular finishing. The shade of every lot of the finished fabric is verified with data color brand color matching system. Dyeing Capacity: 35 Tons dyed fabric per day Total Machine: 92 Nos. TYPE BRAND MACHINE QUANTITY Dyeing machine Fong’s 47 nos. Dewatering & detwisting MC. Santex 02 nos. Dewatering & detwisting MC. Bianco 01 nos. Efficient shrinkage dryer Fong’s 01 nos. Santa shrink jumbo dryer Santex 01 nos. Compactor (tubler) Tube-tex 03 nos. Open width compactor Tube-tex 01 nos. Open width compactor Bruckner 01 nos. Slitting machine Bianco 03 nos. Stenter Tube-tex 01 nos. Stenter Bruckner 02 nos. Sueding machine Lafer 02 nos. Raising machine Gematex 01 nos. Shearing machine Gematex 01 nos. Singeing machine Osthoff 01 nos. Turning machine Puji/Hsing Cheng/Daroitex 05 nos. Back Sewing machine GMT 03 nos. Steam Setting machine Dong Nang 02 nos. Grey Fabric Check machine UZU 09 nos. Finish Fabric Check machine Daroitex/Hsing Cheng 05 nos. Total 92 nos.

- 27. Industrial Attachment Page 22 of 229 BACK SEWING MACHINE Machine No.: KDBS - 1 Model: CCM220 Serial no.: C05-012 No. of motor: 4 Year built : 2005 Machine No.: KDBS - 2 Model: MTG Serial no.: C07-067 Country of origin : Italy No. of motor: 4 Year built : 2007 Machine No.: KDBS - 3 Model: CCM-260 Serial no.: C08-035 No. of motor: 4 Year built : 2008 Machine No.: KDBS - 4 Model: PTD - 100 Serial no.: 20105022 Power: 400 V @ 50 Hz

- 28. Industrial Attachment Page 23 of 229 TURNING MACHINE Machine No.: KDT - 2 Brand name: HSING CHENG Model: HC-TFM Country of origin : Thailand Power: 400 V @ 50 Hz Machine No.: KDT - 3 Brand name: HSING CHENG Model: HC-TFM Country of origin : Thailand Power: 400 V @ 50 Hz Machine No.: KDT - 5 Brand name: PUNGI Model: P-RP/F Serial no.: 451050001 Country of origin : Italy Power: 400 V @ 50 Hz

- 29. Industrial Attachment Page 24 of 229 DYEING MACHINES LAYOUT OF DYEING FLOOR ( KCL + KCAL): Tubular finishing area Office Storage Batching area KCL (Dyeing floor) KCL (Dyeing floor) Office + Chemical store Open width finishing area KCAL (Dyeing floor)

- 30. Industrial Attachment Page 25 of 229 Dryer LAYOUT OF DYEING FLOOR (KCL): Dyeing m/cs Compacting m/cs Squeezer m/cs Dyeing m/cs Office KCAL floor

- 31. Industrial Attachment Page 26 of 229 Dyeingm/cs LAYOUT OF DYEING FLOOR (KCAL): Dyeing m/cs Compacting m/cs Sliting m/cs Stenter Stenter

- 32. Industrial Attachment Page 27 of 229 MACHINE DETAILS Machine No.: 01 Brand name: FONG’S Model: GN 6-SR -6T Serial no.:26012102 Country of origin : China Machine type: HTHP Machine Machine capacity: 1200 Kg No. of nozzle: 6 No. of motor: 9 Power: 415 V @ 50 Hz Year built : 2002 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 585 KPa Safety valve set 700 KPa 380 KPa Heating/ cooling medium Steam Dye liquor

- 33. Industrial Attachment Page 28 of 229 Machine No.: 2A Brand name: FONG’S Model: GN 6-SR -4T Serial no.:26012101 Country of origin : China Machine type: HTHP Machine Machine capacity: 800 Kg No. of nozzle: 4 No. of motor: 7 Power: 415 V @ 50 Hz Year built : 2002 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 585 KPa Safety valve set 700 KPa 380 KPa Heating/ cooling medium Steam Dye liquor

- 34. Industrial Attachment Page 29 of 229 Machine No.: 01A Brand name: FONG’S Model: MSR Serial no.: 34025441H Country of origin : China Machine Type: HTHP machine Machine capacity: 2000 Kg No. of nozzle: 8 No. of motor: 18 Power: 415 V @ 50 Hz Year built : 2009 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1100 KPa 520 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 35. Industrial Attachment Page 30 of 229 Machine No.: 3A Brand name: FONG’S Model: GN-6 SR-3T Serial no.: 26012100 Country of origin : China Machine type: HTHP machine Machine capacity: 600 Kg No. of nozzle: 3 No. of motor: 7 Power: 415 V @ 50 Hz Year built : 2002 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 585 KPa Safety valve set 700 KPa 380 KPa Heating/ cooling medium Steam Dye liquor

- 36. Industrial Attachment Page 31 of 229 Machine No.: 4B Brand name: FONG’S Model: HSJ-2T Serial no.: 34026089 Country of origin : China Machine type: HTHP machine Machine capacity : 500 Kg No. of nozzle : 2 No. of motor: 10 Power: 415 V @ 50 Hz Year built : 2010 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 37. Industrial Attachment Page 32 of 229 Machine No.: 5A Brand name: FONG’S Model: HSJ-1T Serial no.:33024653 Country of origin : China Machine type: HTHP machine Machine capacity : 250 Kg No. of nozzle : 1 No. of motor: 7 Power: 415 V @ 50 Hz Year built : 2010 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 38. Industrial Attachment Page 33 of 229 Machine No.: 4D Brand name: FONG’S Model: GN-6-2T Serial no.: 28015334 Country of origin : China Machine type: HTHP machine Machine capacity : 400 Kg No. of nozzle : 2 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 585 KPa Safety valve set 700 KPa 380 KPa Heating/ cooling medium Steam Dye liquor

- 39. Industrial Attachment Page 34 of 229 Machine No.: 4C Brand name: FONG’S Model: HSJ-2T Serial no.: 34026088 Country of origin : China Machine type: HTHP machine Machine capacity : 400 Kg No. of nozzle : 2 No. of motor: 9 Power: 415 V @ 50 Hz Year built : 2010 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 40. Industrial Attachment Page 35 of 229 Machine No.: 9B Brand name: FONG’S Model: ALLFIT-100 Serial no.: 31020952T Country of origin : China Machine type: HTHP machine Machine capacity : 100 Kg No. of nozzle : 2 No. of motor: 4 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 41. Industrial Attachment Page 36 of 229 Machine No.: 9C Brand name: FONG’S Model: ALLFIT-60 Serial no.: 31020952T Country of origin : China Machine type: HTHP machine Machine capacity : 60 Kg No. of nozzle : 1 No. of motor: 4 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 42. Industrial Attachment Page 37 of 229 Machine No.: 4E Brand name: FONG’S Model: HSJ-2T Serial no.: 31020092 Country of origin : China Machine type: HTHP machine Machine capacity : 500 Kg No. of nozzle : 2 No. of motor: 9 Power: 415 V @ 50 Hz Year built : 2008 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 43. Industrial Attachment Page 38 of 229 Machine No.: 8B Brand name: FONG’S Model: ECO-38-3T Serial no.: 31020955 Country of origin : China Machine type: Environmental Machine capacity : 750 Kg No. of nozzle : 3 No. of motor: 9 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 44. Industrial Attachment Page 39 of 229 Machine No.: 7C Brand name: FONG’S Model: HSJ-4T Serial no.: 34025440 Country of origin : China Machine type: HTHP machine Machine capacity : 1000 Kg No. of nozzle : 4 No. of motor: 12 Power: 415 V @ 50 Hz Year built : 2008 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 45. Industrial Attachment Page 40 of 229 Machine No.: 6A Brand name: FONG’S Model: ECO-38-6T Serial no.: 28014582 Country of origin : China Machine type: Environmental Machine capacity : 1500 Kg No. of nozzle : 6 No. of motor: 11 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 46. Industrial Attachment Page 41 of 229 Machine No.: 6B Brand name: FONG’S Model: ECO-38-6T Serial no.: 28014581 Country of origin : China Machine type: Environmental Machine capacity : 1500 Kg No. of nozzle : 6 No. of motor: 10 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 47. Industrial Attachment Page 42 of 229 Machine No.: 7A Brand name: FONG’S Model: ECO-38-4T Serial no.: 28015424 Country of origin : China Machine type: Environmental Machine capacity : 1000 Kg No. of nozzle : 4 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 48. Industrial Attachment Page 43 of 229 Machine No.: 7B Brand name: FONG’S Model: ECO-38-4T Serial no.: 28015423 Country of origin : China Machine type: Environmental Machine capacity : 1000 Kg No. of nozzle : 4 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 49. Industrial Attachment Page 44 of 229 Machine No.: 8A Brand name: FONG’S Model: ECO-38-3T Serial no.: 28015422 Country of origin : China Machine type: Environmental Machine capacity : 750 Kg No. of nozzle : 3 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 50. Industrial Attachment Page 45 of 229 Machine No.: 4PA Brand name: FONG’S Model: GN-8-500 Serial no.: 31020958 Country of origin : China Machine type: Environmental Machine capacity : 500 Kg No. of nozzle : 2 No. of motor: 5 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 51. Industrial Attachment Page 46 of 229 Machine No.: 5PA Brand name: FONG’S Model: GN-8-250 Serial no.: 31020957 Country of origin : China Machine type: Environmental Machine capacity : 200 Kg No. of nozzle : 1 No. of motor: 4 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 52. Industrial Attachment Page 47 of 229 Machine No.: 10 Brand name: FONG’S Model: ALLFIT-60-2T Serial no.: 26012103 Country of origin : China Machine type: HTHP machine Machine capacity : 100 Kg No. of nozzle : 2 No. of motor: 5 Power: 415 V @ 50 Hz Year built : 2001 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 53. Industrial Attachment Page 48 of 229 Machine No.: 12 Brand name: FONG’S Model: GN-18-ST-10 Serial no.: 24010324 Country of origin : China Machine type: Environmental Machine capacity : 100 Kg No. of nozzle : 1 No. of motor: 6 Power: 415 V @ 50 Hz Year built : 2000 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 54. Industrial Attachment Page 49 of 229 Machine No.: 14A Brand name: FONG’S Model: ECO-38-1T Serial no.: 2801420 Country of origin : China Machine type: Environmental Machine capacity : 150 Kg No. of nozzle : 1 No. of motor: 7 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 55. Industrial Attachment Page 50 of 229 Machine No.: 14B Brand name: FONG’S Model: ECO-38-1T Serial no.: 2801421 Country of origin : China Machine type: Environmental Machine capacity : 150 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 56. Industrial Attachment Page 51 of 229 Machine No.: 14C Brand name: FONG’S Model: ECO-38-1T Serial no.: 28015419 Country of origin : China Machine type: Environmental Machine capacity : 150 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 57. Industrial Attachment Page 52 of 229 Machine No.: 14D Brand name: FONG’S Model: ECO-38-1T Serial no.: 28015418 Country of origin : China Machine type: Environmental Machine capacity : 150 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 58. Industrial Attachment Page 53 of 229 Machine No.: 14E Brand name: FONG’S Model: ECO-38-1T Serial no.: 28015415 Country of origin : China Machine type: Environmental Machine capacity : 150 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 59. Industrial Attachment Page 54 of 229 Machine No.: 11A Brand name: FONG’S Model: ALLFIT-30 Serial no.: 26011959 Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2003 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 60. Industrial Attachment Page 55 of 229 Machine No.: 11B Brand name: FONG’S Model: ALLFIT-30 Serial no.: 29017180 Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2004 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 61. Industrial Attachment Page 56 of 229 Machine No.: 11C Brand name: FONG’S Model: ALLFIT-30 Serial no.: 29017183 Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2004 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 62. Industrial Attachment Page 57 of 229 Machine No.: 11D Brand name: FONG’S Model: ALLFIT-30 Serial no.: 29017182 Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2004 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 63. Industrial Attachment Page 58 of 229 Machine No.: 11E Brand name: FONG’S Model: ALLFIT-30 Serial no.: 29017181 Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg No. of nozzle : 1 No. of motor: 8 Power: 415 V @ 50 Hz Year built : 2004 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 64. Industrial Attachment Page 59 of 229 Machine No.: 13G Brand name: FONG’S Model: ALLFIT-10 Serial no.: 32022971 Country of origin : China Machine type: HTHP machine Machine capacity : 10 Kg No. of nozzle : 1 No. of motor: 3 Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1100 KPa 520 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 65. Industrial Attachment Page 60 of 229 Machine No.: 11G Brand name: FONG’S Model: ALLFIT-30 Serial no.: 31020952T Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg No. of nozzle : 1 No. of motor: 4 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 66. Industrial Attachment Page 61 of 229 Machine No.: 11F Brand name: FONG’S Model: ALLFIT-30 Serial no.: 31020952T Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg No. of nozzle : 1 No. of motor: 4 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 67. Industrial Attachment Page 62 of 229 Machine No.: 13F Brand name: FONG’S Model: ALLFIT-10 Serial no.: 31020952T Country of origin : China Machine type: HTHP machine Machine capacity : 10 Kg No. of nozzle : 1 No. of motor: 4 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 68. Industrial Attachment Page 63 of 229 Machine No.: 13E Brand name: FONG’S Model: ALLFIT-10 Serial no.: 31020952T Country of origin : China Machine type: HTHP machine Machine capacity : 10 Kg No. of nozzle : 1 No. of motor: 4 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 400 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 650 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 69. Industrial Attachment Page 64 of 229 Machine No.: 7D Brand name: FONG’S Model: HSJ-4T Serial no.: 34025440 Country of origin : China Machine type: HTHP machine Machine capacity : 1000 Kg No. of nozzle : 4 No. of motor: 12 Power: 415 V @ 50 Hz Year built : 2008 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 70. Industrial Attachment Page 65 of 229 Machine No.: 4F Brand name: FONG’S Model: HSJ-2T Serial no.: 31020092 Country of origin : China Machine type: HTHP machine Machine capacity : 500 Kg No. of nozzle : 2 No. of motor: 9 Power: 415 V @ 50 Hz Year built : 2008 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1100 KPa 520 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 71. Industrial Attachment Page 66 of 229 Machine No.: 5B Brand name: FONG’S Model: HSJ-1T Serial no.:33024653 Country of origin : China Machine type: HTHP machine Machine capacity : 250 Kg No. of nozzle : 1 No. of motor: 7 Power: 415 V @ 50 Hz Year built : 2010 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 350 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 540 KPa Safety valve set 700 KPa 350 KPa Heating/ cooling medium Steam Dye liquor

- 72. Industrial Attachment Page 67 of 229 Machine No.: 13B Brand name: UGOLONI Machine capacity : 20 Kg Machine No.: 8C Brand name: FONG’S Model: ECO-38-3T Serial no.: 31020956 Country of origin : China Machine type: Environmental Machine capacity : 750 Kg No. of nozzle : 3 No. of motor: 9 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 73. Industrial Attachment Page 68 of 229 Machine No.: 4A Brand name: FONG’S Model: ECO-38-2T Serial no.: 31020959 Country of origin : China Machine type: Environmental Machine capacity : 300 Kg No. of nozzle : 2 No. of motor: 9 Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa ATM Design temperature 170 °C 98 °C Hydrolic test pressure 1200 KPa - Safety valve set 700 KPa - Heating/ cooling medium Steam Dye liquor

- 74. Industrial Attachment Page 69 of 229 FINISHING OPEN WIDTH FINISHING SLITING MACHINE Machine No.: KDSL - 1 Brand name: BIANCO Serial no.: M05305-023517 Country of origin : Italy No. of motor: 13 Maximum speed: 90 m/min. Year built : 2006 Machine No.: KDSL - 2 Brand name: BIANCO Serial no.: M05305-023517 Country of origin : Italy No. of motor: 13 Maximum speed: 90 m/min. Year built : 2006 Machine No.: KDSL - 3 Brand name: BIANCO Serial no.: M05304-023517 Country of origin : Italy

- 75. Industrial Attachment Page 70 of 229 No. of motor: 13 Maximum speed: 90 m/min. Year built : 2006 STANTER MACHINE Machine No.: KDST - 2 Brand name: BRUCKNER Country of origin : Germany Machine type: VN-SFP-26/8-999 Heating type: Thermosol oil Maximum temperature: 210 °C Year built : 2006 POWER-PAD padder: Type: FS-2 Year built : 2006 Maximum steam pressure: 2 bar Maximum air pressure: 10 bar Machine No.: KDST - 3 Brand name: BRUCKNER Country of origin : Germany Machine type: VN-SFP-26/8-999 Heating type: Gas

- 76. Industrial Attachment Page 71 of 229 Maximum temperature: 210 °C Year built : 2008 POWER-PAD padder: Type: power pad Year built : 2008 Maximum steam pressure: 0.7 bar Maximum air pressure: 10 bar Compacting machine Machine No.: KDCM - 3 Brand name: TUBE TEX Country of origin : USA Machine type: C 2000 Heating type: Steam Machine No.: KDCM - 5 Brand name: BRUCKNER Country of origin : Germany Machine type: OC-28+SV-28 Heating type: Steam Year built : 2007

- 77. Industrial Attachment Page 72 of 229 Figure: Stenter machine TUBULAR WIDTH FINISHING Flow chart: Squeezer Dryer Turning Steam setting machine Compacting QC

- 78. Industrial Attachment Page 73 of 229 SQUEEZER Machine No.: KDS - 1 Brand name: SANTEX AG Sirial no.: 5926 Country of origin : Switzerland Model: Santastretch Plus Year built : 2003 Machine No.: KDS - 2 Brand name: SANTEX AG Sirial no.: 5927 Country of origin : Switzerland Model: Santastretch Plus Year built : 2003 Machine No.: KDS - 3 Brand name: BIANCO Sirial no.: M05794-025719 Country of origin : Italy Model: Santastretch Plus Maximum speed: 80 m/min. Year built : 2007

- 79. Industrial Attachment Page 74 of 229 DRYER Machine No.: KDD - 1 Brand name: FONG’S Sirial no.: 23009238 Model: ESD28D2 Country of origin : Hong-kong Power: 415 V @ 50 Hz Heating type: Steam Maximum temperature: 200 °C No. of blower: 3 Year: 2003 Machine No.: KDD - 2 Brand name: SANTEX AG Sirial no.: 5927 Type: Santashrink 3KJ/300GF1 IR Dampf Country of origin : Switzerland Power: 400 V @ 50 Hz Heating type: Steam Maximum temperature: 200 °C No. of blower: 3 Year: 2003

- 80. Industrial Attachment Page 75 of 229 TURNING Machine No.: KDT - 1 Brand name: DAROITEX Model: DSR-3000 Country of origin : Italy Power: 414 V @ 50 Hz Year: 2006 Machine No.: KDT - 2 Brand name: DAROITEX Model: DSR-3000 Country of origin : Italy Power: 414 V @ 50 Hz Year: 2006 STEAM SETTING MACHINE Machine No.: KDHS - 1 Brand name: DONGNAM Sirial no.: DN-0509 Model: DNS-1400 Country of origin : Korea Power: 415 V @ 50 Hz Heating type: Steam

- 81. Industrial Attachment Page 76 of 229 Year: 2005 Machine No.: KDHS - 2 Brand name: DONGNAM Sirial no.: DN-0613 Model: DNS-1400 Country of origin : Korea Power: 415 V @ 50 Hz Heating type: Steam Year: 2006 COMPACTING MACHINE Machine No.: KDCM - 1 Brand name: Navis Tube-tex Sirial no.: 10421 Model: Pak-nit II SP Country of origin : U.S.A. Power: 415 V @ 50 Hz Heating type: Steam & oil Machine No.: KDCM - 2 Brand name: Tube-tex Sirial no.: 10631 Model: Pak-nit II Delta Plus - SP

- 82. Industrial Attachment Page 77 of 229 Country of origin : U.S.A. Power: 415 V @ 50 Hz Heating type: Steam & oil Machine No.: KDCM - 4 Brand name: Tube-tex Sirial no.: BM-9847 Model: Pak-nit II Delta Plus Country of origin : U.S.A. Power: 415 V @ 50 Hz Heating type: Steam & oil QC INSPECTION MACHINE Machine No.: KDQCM - 1 Brand name: DAROITEX Machine type: Inspecting machine Sirial no.: 301 Model: QCM-F Country of origin : Italy Year: 2002 Machine No.: KDQCM - 2 Brand name: Hsing Cheng

- 83. Industrial Attachment Page 78 of 229 Machine type: Inspecting machine Model: HC-GIM-2400mm Country of origin : Tailand Machine No.: KDQCM - 3 Brand name: DAROITEX Machine type: Inspecting machine Model: QCM/R PLATTER Country of origin : Italy Power: 422 V @ 50 Hz Year: 2006 Machine No.: KDQCM - 4 Brand name: Hsing Cheng Machine type: Inspecting machine Model: HC-TIW-3000mm-A19179 Country of origin : Taiwan Year: 2010 Machine No.: KDQCM - 5 Brand name: Hsing Cheng Machine type: Inspecting machine Model: HC-TIW-3000mm-A19179 Country of origin : Taiwan

- 84. Industrial Attachment Page 79 of 229 16'-0"58'-0" 19'-23/8" Supervisor’s desk 19'-23/8" 19'-23/8" 19'-23/8" 19'-23/8" 60'-0" Year: 2010 SPECIAL FINISHING Layout plan 144'-0" 22'-0" Sueding Machine ULTRA SOFT-L 22'-0" Raising Machine GEMATEX 22'-0" Sueding Machine ULTRA SOFT-Y 22'-0" Shearing Machine GEMATEX 22'-0" Singeing Machine OSTHOFF 8'-0" Temporary open storage 144'-0" SUEDING MACHINE Machine No.: KDLS - 01 Brand name: Lafer Machine type: Sueding machine Sirial no.: 10GSX1952 Model: ULTRA SOFT-L Power: 400 V @ 50 Hz Connected load: 25 kW No. of roller: 6 Country of origin : Italy Year: 2005

- 85. Industrial Attachment Page 80 of 229 Filter: Code: SW12L Serial no.: 726L03 Connected load: 25 kW Year: 2005 Machine No.: KDLS - 02 Brand name: Lafer Machine type: Sueding machine Sirial no.: 10GSY2393 Model: ULTRA SOFT-Y Power: 400 V @ 50 Hz No. of roller: 4 Country of origin : Italy Year: 2005 RAISING MACHINE Machine No.: KDR - 1 Brand name: GEMATEX Machine type: Raising machine Country of origin : Germany No. of pile roller: 12 No. of counter pile roller: 12

- 86. Industrial Attachment Page 81 of 229 Power: 400 V @ 50 Hz SHEARING MACHINE Machine No.: KDR - 02 Brand name: GEMATEX Serial no.: 300.103 Machine type: Shearing machine Country of origin : Germany No. of brushing roller: 1 No. of shearing roller: 1 Connected load: 15kW Power: 400 V @ 50 Hz Year: 2007 SINGEING MACHINE Machine No.: KDSG - 01 Brand name: Osthoff Serial no.: 7000 Machine type: Singeing machine Country of origin : Germany Model: WW2006 Temperature range: (40 - 200) °C Speed range: (15 - 100) m/min.

- 87. Industrial Attachment Page 82 of 229 Working width: 2400 mm No. of gas burner: 2 Power: 400 V @ 50 Hz Year: 2008 Figure: Osthoff singeing machine

- 88. Industrial Attachment Page 83 of 229 WASHING UNIT Daily Washing Capacity : Pigment Dyeing : 3000 Pcs. Acid Dyeing : 3000 Pcs. Garment Wash : 50000 Pcs. Ready Dye : 3000 Pcs. MACHINE DETAILS 01. Industrial Washing 10 nos. 02. Tumble Dryer 08 nos. 03. Hydro Extractor 03 nos. 04. Pigment Dyeing 01 no. 05. Garments Dyeing 01 no. 06. Deep Dyeing 01 no.

- 89. Industrial Attachment Page 84 of 229 YARN DYEING Yarn Dyeing Capacity: 25 Tons per day Total Machine: 81 Nos. TYPE BRAND MACHINE QUANTITY Yarn Dyeing M/C Fongs, China 48 Nos. Soft Winding M/C SSM, Switzerland 05 Soft Winding M/C Fadis, Italy 02 Hard Winding M/C SSM, Switzerland 03 Hard Winding M/C Fadis, Italy 02 Aquasplicer Mesdan, Italy 08 Soft Thread Winding SSM, Switzerland 01 Hydro Dettin, Italy 02 Dryer Stryfield, England 02 Dryer Stalam, Italy 01 Auto Dosing Silos-Dos Lawer, Italy 02 Dos-Chem Lawer, Italy 04 Rotary Dyes Store Lawer, Italy 01 Total 81

- 90. Industrial Attachment Page 85 of 229 Figure: Yarn dyeing floor

- 91. Industrial Attachment Page 86 of 229 Figure: Silos-Dos (Lawer) General flow chart: Soft winding Dyeing Hydro extraction Drying Hard winding

- 92. Industrial Attachment Page 87 of 229 Toilet Temporaryopenstorage stair stair Supervisor’s desk SOFT WINDING Layout plan of soft winding floor 12 8 1 13 9 5 2 14 10 6 3 15 11 7 4 Temporary open storage Lift Lift 1-15 : Soft winding machines Machine No.: 1 Brand name: SSM Country of origin : Switzerland Machine type: TW2-W Serial no.: 856.0130/06 No. of spindle: 78 Imax: 38 A U: 400 V @ 50 Hz

- 93. Industrial Attachment Page 88 of 229 Machine No.: 2 Brand name: SSM Country of origin : Switzerland Machine type: TW2-W Serial no.: 856.0130/06 No. of spindle: 60 Imax: 38 A U: 400 V @ 50 Hz Machine No.: 3 Brand name: SSM Country of origin : Switzerland Machine type: TW2-W Serial no.: 856.0130/06 No. of spindle: 60 Imax: 38 A U: 400 V @ 50 Hz Machine No.: 4 Brand name: SSM-P26 Country of origin : Switzerland Machine type: PS6 Plus-W Serial no.: 883.1066/10

- 94. Industrial Attachment Page 89 of 229 No. of spindle: 60 Imax: 25 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 5 Brand name: SSM Country of origin : Switzerland Machine type: PS6 -W Serial no.: 883.0427/06 No. of spindle: 60 Imax: 32 A U: 400 V @ 50 Hz Year: 2007 Machine No.: 6 Brand name: SSM Country of origin : Switzerland Machine type: PS6 -W Serial no.: 883.0429/06 No. of spindle: 60 Imax: 32 A U: 400 V @ 50 Hz

- 95. Industrial Attachment Page 90 of 229 Year: 2007 Machine No.: 7 Brand name: SSM Country of origin : Switzerland Machine type: PS6 -W Serial no.: 883.0427/06 No. of spindle: 60 Imax: 32 A U: 400 V @ 50 Hz Year: 2007 Machine No.: 8 Brand name: Fadis-Sincro Country of origin : Italy Machine type: FT P300 Serial no.: G0023DX No. of spindle: 96 U: 400 V @ 50 Hz Machine No.: 9 Brand name: SSM-P26 Country of origin : Switzerland Machine type: PS6 Plus-W

- 96. Industrial Attachment Page 91 of 229 Serial no.: 883.1060/10 No. of spindle: 60 Imax: 25 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 10 Brand name: SSM-P26 Country of origin : Switzerland Machine type: PS6 Plus-W Serial no.: 883.1062/10 No. of spindle: 60 Imax: 25 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 11 Brand name: SSM-P26 Country of origin : Switzerland Machine type: PS6 Plus-W Serial no.: 883.1063/10 No. of spindle: 60 Imax: 25 A

- 97. Industrial Attachment Page 92 of 229 U: 400 V @ 50 Hz Year: 2011 Machine No.: 12 Brand name: Fadis-Sincro Country of origin : Italy Machine type: FT P300 Serial no.: G0023DX No. of spindle: 96 U: 400 V @ 50 Hz Machine No.: 13 Brand name: SSM-P26 Country of origin : Switzerland Machine type: PS6 Plus-W Serial no.: 883.1059/10 No. of spindle: 60 Imax: 25 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 14 Brand name: SSM-P26 Country of origin : Switzerland

- 98. Industrial Attachment Page 93 of 229 Machine type: PS6 Plus-W Serial no.: 883.1061/10 No. of spindle: 60 Imax: 25 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 15 Brand name: SSM-P26 Country of origin : Switzerland Machine type: PS6 Plus-W Serial no.: 883.1064/10 No. of spindle: 60 Imax: 25 A U: 400 V @ 50 Hz Year: 2011

- 99. HydroExtractor BIDmachine MicroWin LabWin 6578 RotaryDyesStore stair 3412 312 stair DYEING Layout plan of dyeing floor RF Dryer Yarn storage Chemical storage Office Lift Lift 4 5 Silos-Dos 6 8 7 All Win 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Dos-Chem Lift Lab Win 6 2 3 4 5 All Win Yarn Conditioner Industrial Attachment Page 94 of 229

- 100. Industrial Attachment Page 95 of 229 MICROWIN Machine No.: 1 Brand name: FONG’S Model: Microwin Serial no.: 35027707 Country of origin : China Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz Year built : 2011 Machine No.: 2 Brand name: FONG’S Model: Microwin Serial no.: 35027751 Country of origin : China Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz Year built : 2011 Machine No.: 3 Brand name: FONG’S

- 101. Industrial Attachment Page 96 of 229 Model: Microwin Serial no.: 35027748 Country of origin : China Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz Year built : 2011 Machine No.: 4 Brand name: FONG’S Model: Microwin Serial no.: 35027746 Country of origin : China Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz Year built : 2011 Machine No.: 5 Brand name: FONG’S Model: Microwin Serial no.: 35027749 Country of origin : China

- 102. Industrial Attachment Page 97 of 229 Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz Year built : 2011 Machine No.: 6 Brand name: FONG’S Model: Microwin Serial no.: 33024288T Country of origin : China Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz Year built : 2011 Machine No.: 7 Brand name: FONG’S Model: Microwin Serial no.: 30203973T Country of origin : China Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz

- 103. Industrial Attachment Page 98 of 229 Year built : 2011 Machine No.: 8 Brand name: FONG’S Model: Microwin Serial no.: 35027750 Country of origin : China Machine type: HTHP Machine Machine capacity: 350 gm Power: 415 V @ 50 Hz Year built : 2011

- 104. Industrial Attachment Page 99 of 229 LABWIN Machine No.: 2 Brand name: FONG’S Model: LABWIN 12-K1 Serial no.: 31021466 Country of origin : China Machine type: HTHP machine Machine capacity : 14Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Jacket Shell Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 3 Brand name: FONG’S Model: LABWIN 12-K1 Serial no.: 31021467 Country of origin : China

- 105. Industrial Attachment Page 100 of 229 Machine type: HTHP machine Machine capacity : 14Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Jacket Shell Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 4 Brand name: FONG’S Model: LABWIN 6-KO Serial no.: 31021465 Country of origin : China Machine type: HTHP machine Machine capacity : 7Kg Power: 415 V @ 50 Hz Year built : 2007

- 106. Industrial Attachment Page 101 of 229 Heat exchanger: Parameters Jacket Shell Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 5 Brand name: FONG’S Model: LABWIN 6-KO Serial no.: 31020961 Country of origin : China Machine type: HTHP machine Machine capacity : 7Kg Power: 415 V @ 50 Hz Year built : 2006 Heat exchanger: Parameters Jacket Shell Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor

- 107. Industrial Attachment Page 102 of 229 Machine No.: 6 Brand name: FONG’S Model: LABWIN 6-KO Serial no.: 33024652 Country of origin : China Machine type: HTHP machine Machine capacity : 7Kg Power: 415 V @ 50 Hz Year built : 2008 Heat exchanger: Parameters Jacket Shell Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor

- 108. Industrial Attachment Page 103 of 229 ALLWIN Machine No.: 1 Brand name: FONG’S Model: ALLWIN-43-6A Serial no.: 31021468 Country of origin : China Machine type: HTHP machine Machine capacity : 30 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 2 Brand name: FONG’S Model: ALLWIN-53 Serial no.: 31021469 Country of origin : China

- 109. Industrial Attachment Page 104 of 229 Machine type: HTHP machine Machine capacity : 50 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 3 Brand name: FONG’S Model: ALLWIN-53-8A Serial no.: 31021470 Country of origin : China Machine type: HTHP machine Machine capacity : 60 Kg Power: 415 V @ 50 Hz Year built : 2007

- 110. Industrial Attachment Page 105 of 229 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 4 Brand name: FONG’S Model: ALLWIN-70-9A Serial no.: 31020960 Country of origin : China Machine type: HTHP machine Machine capacity : 100 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor

- 111. Industrial Attachment Page 106 of 229 Machine No.: 5 Brand name: FONG’S Model: ALLWIN-85-9A Serial no.: 31021471 Country of origin : China Machine type: HTHP machine Machine capacity : 200 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 6 Brand name: FONG’S Model: ALLWIN-85-9A Serial no.: 31021472 Country of origin : China Machine type: HTHP machine

- 112. Industrial Attachment Page 107 of 229 Machine capacity : 200 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 7 Brand name: FONG’S Model: ALLWIN-120-9A Serial no.: 32022972 Country of origin : China Machine type: HTHP machine Machine capacity : 400 Kg Power: 415 V @ 50 Hz Year built : 2007

- 113. Industrial Attachment Page 108 of 229 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 8 Brand name: FONG’S Model: ALLWIN-120-9A Serial no.: 31021473 Country of origin : China Machine type: HTHP machine Machine capacity : 400 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor

- 114. Industrial Attachment Page 109 of 229 Machine No.: 9 Brand name: FONG’S Model: ALLWIN-145-9A Serial no.: 32023066 Country of origin : China Machine type: HTHP machine Machine capacity : 600 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 10 Brand name: FONG’S Model: ALLWIN-145-9A Serial no.: 32023065 Country of origin : China Machine type: HTHP machine

- 115. Industrial Attachment Page 110 of 229 Machine capacity : 600 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 11 Brand name: FONG’S Model: ALLWIN-145-9A Serial no.: 31021474 Country of origin : China Machine type: HTHP machine Machine capacity : 600 Kg Power: 415 V @ 50 Hz Year built : 2007

- 116. Industrial Attachment Page 111 of 229 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 12 Brand name: FONG’S Model: ALLWIN-145-12A Serial no.: 31021475 Country of origin : China Machine type: HTHP machine Machine capacity : 800 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor

- 117. Industrial Attachment Page 112 of 229 Machine No.: 13 Brand name: FONG’S Model: ALLWIN-166-12A Serial no.: 31021476 Country of origin : China Machine type: HTHP machine Machine capacity : 1000 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor Machine No.: 14 Brand name: FONG’S Model: ALLWIN-205-12A Serial no.: 31021477 Country of origin : China Machine type: HTHP machine

- 118. Industrial Attachment Page 113 of 229 Machine capacity : 1600 Kg Power: 415 V @ 50 Hz Year built : 2007 Heat exchanger: Parameters Shell Tube Design pressure 700 KPa 520 KPa Design temperature 170 °C 140 °C Hydrolic test pressure 1200 KPa 800 KPa Safety valve set 700 KPa 520 KPa Heating/ cooling medium Steam Dye liquor

- 119. Industrial Attachment Page 114 of 229 HDRO-EXTRACTOR Machine No.: 1 Brand name: Dettin Benta Model: 1205568 Serial no.: 0155 Country of origin : Italy Machine capacity : 108 Kg Power: 400 V @ 50 Hz Year built : 2007 Machine No.: 2 Brand name: Dettin Benta Model: 1205568 Serial no.: 0154 Country of origin : Italy Machine capacity : 108 Kg Power: 400 V @ 50 Hz Year built : 2007 Machine No.: 3 Brand name: Dettin Benta Model: 1205568 Serial no.: B11053

- 120. Industrial Attachment Page 115 of 229 Country of origin : Italy Machine capacity : 108 Kg Power: 400 V @ 50 Hz Year built : 2011 Machine No.: 4 Brand name: Dettin Benta Model: 1205568 Serial no.: B11052 Country of origin : Italy Machine capacity : 108 Kg Power: 400 V @ 50 Hz Year built : 2011 LAIP DYEING MACHINE Bobbin Injection Dyeing Machine Machine type: Type R Code: C1055 No. of motor: 6 No. of color tank: 4 Year built: 2011

- 121. Industrial Attachment Page 116 of 229 YARN CONDITIONING MACHINE Model: Steamer VS/HT Machine type: D 1450 Code: C0924 Pressure: 0.27 MPa Year built: 2011 DRYING Machine No.: 1 Brand name: RF Model: S0100/TE Serial no.: 89350T Country of origin : UK Machine type: Radio frequancy dryer Frequancy used: 27 mHz Power: (380- 420) V @ 50 Hz Year built: 2007 Machine No.: 2 Brand name: RF Model: S0100/TE Serial no.: 89349T Country of origin : UK

- 122. Industrial Attachment Page 117 of 229 Machine type: Radio frequancy dryer Frequancy used: 27 mHz Power factor: 0.9 Power: (380- 420) V @ 50 Hz Year built: 2007 Machine No.: 3 Brand name: STALAM Model: RF-150 KW Serial no.: 89349T Country of origin : Italy Machine type: Radio frequancy dryer Frequancy used: 27 mHz Power factor: 0.9 Power: 400 V @ 50 Hz Year built: 2009 Machine No.: 4 Brand name: STALAM Model: RF-150 KW Serial no.: 89349T Country of origin : Italy Machine type: Radio frequancy dryer

- 123. Industrial Attachment Page 118 of 229 Toilet Office stair Supervisor’s desk stair Frequancy used: 27 mHz Power factor: 0.9 Power: 400 V @ 50 Hz Year built: 2011 HARD WINDING Layout plan of hard winding floor 9 5 1 Office 765 sq. ft. 10 6 2 11 7 3 12 8 4 HACOBA Lift Lift 1-12 : Hard winding machines Machine No.: 1 Brand name: SSM Country of origin : Switzerland Machine type: CW2-W Serial no.: 863.0029/07 No. of spindle: 96

- 124. Industrial Attachment Page 119 of 229 Imax: 28 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 2 Brand name: SSM Country of origin : Switzerland Machine type: CW2-W Serial no.: 863.0028/07 No. of spindle: 96 Imax: 28 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 3 Brand name: SSM Country of origin : Switzerland Machine type: CW2-W Serial no.: 863.0027/07 No. of spindle: 96 Imax: 28 A U: 400 V @ 50 Hz Year: 2011

- 125. Industrial Attachment Page 120 of 229 Machine No.: 4 Brand name: SSM Country of origin : Switzerland Machine type: CW2-W Serial no.: 863.0080/09 No. of spindle: 96 Imax: 28 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 5 Brand name: Fadis-Sincro Country of origin : Italy Machine type: FT/RT P300 Serial no.: G0025DS No. of spindle: 96 Imax: 16 A U: 440 V @ 50 Hz Year: 2008 Machine No.: 6 Brand name: SSM Country of origin : Switzerland

- 126. Industrial Attachment Page 121 of 229 Machine type: CW8-W Serial no.: 863.1029/11 No. of spindle: 128 Imax: 7 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 7 Brand name: SSM Country of origin : Switzerland Machine type: CW8-W Serial no.: 863.1032/11 No. of spindle: 128 Imax: 7 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 8 Brand name: SSM Country of origin : Switzerland Machine type: CW8-W Serial no.: 863.1030/11 No. of spindle: 128

- 127. Industrial Attachment Page 122 of 229 Imax: 7 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 9 Brand name: Fadis-Sincro Country of origin : Italy Machine type: FT/RT P300 Serial no.: G0024DX No. of spindle: 96 Imax: 16 A U: 440 V @ 50 Hz Year: 2008 Machine No.: 10 Brand name: SSM Country of origin : Switzerland Machine type: CW8-W Serial no.: 863.1028/11 No. of spindle: 128 Imax: 7 A U: 400 V @ 50 Hz Year: 2011

- 128. Industrial Attachment Page 123 of 229 Machine No.: 11 Brand name: SSM Country of origin : Switzerland Machine type: CW8-W Serial no.: 863.1033/11 No. of spindle: 128 Imax: 7 A U: 400 V @ 50 Hz Year: 2011 Machine No.: 12 Brand name: SSM Country of origin : Switzerland Machine type: CW8-W Serial no.: 863.1031/11 No. of spindle: 128 Imax: 7 A U: 400 V @ 50 Hz Year: 2011 SEWING THREAD WINDING MACHINE Machine No.: 1 Brand name: HACOBA

- 129. Industrial Attachment Page 124 of 229 Model: Thread Prince 850C Country of origin : Switzerland Serial no.: 881.1101/06 No. of spindle: 12 Imax: 6.8 A U: 400 V @ 50 Hz Year: 2007 PRINTING Knit Concern is capable of printing all specifications in the range from film to screen developments. It has ability of pigment, silicon, puff, flock, glitter, metal stone and rub- ber printing with equal proficiency. It can print 100000 pieces of garments a day in a sin- gle design; it is capable of printing in 12 colors. MACHINE DETAILS PRINTING MACHINE NAME MACHINE QUANTITY Auto printing machine 4 Nos. Conveyor curing machine 8 Nos. Hit press machine 14 Nos. Stone machine 5 Nos. Flock machine 12 Nos. Spray printing unit 1 Nos. Printing table 4000 meters Flock suckering machine 2 Nos. Generator 3 Nos. Mex newton 2 set Auto exposing unit 1 set

- 130. Industrial Attachment Page 125 of 229 Manual exposing unit 3 set CENTRAL LAB Laboratory is an independent department. It plays a critical role in every production phase especially in knitting, fabric dyeing and yarn dyeing section manufacturing the quality standard. Type Brand MC. Qty. Wet Lab Wascator Electrolux 05 Nos. T. Dryer SDL 03 Nos. Rote – wash SDL 01 Nos. Perspirometer & Ovenincubator SDL+J.H.Heals 01 Nos. Light fastness tester J.H.Heals 01 Nos. Conditioned Lab Elec - Crockmeter SDL 01 Nos. ICI Pill box SDL+J.H.Heals 02 Nos. TPI Tester SDL 02 Nos. Yarn appearance Tester SDL 01 Nos. Yarn count system Brustio 01 Nos. Tru – Brust J.H.Heals 01 Nos. Conditioning system OEDA 01 Nos. Analytical Lab Formaldehyde Tester Parkins Elamar 01 Nos. Knit machine Lab Auto – Lab Dispense (40cmb) Datacolor 01 Nos.

- 131. Industrial Attachment Page 126 of 229 Ahiba Infrared Dryer Datacolor 02 Nos. Spectrophotometer – SF600CT Datacolor 01 Nos. Data color Conditioner Datacolor 01 Nos. Yarn Machine Lab Auto – lab Dispense (120CMB) Datacolor 01 Nos. Ahiba Infrared Dryer Datacolor 03 Nos. Spectrophotometer – 650x Datacolor 01 Nos. Total 31 Nos. KNIT DYEING LAB Auto lab dispansing machine Machine No.: KDSM - 01 Brand name: LAWER Serial no.: 2629 Model: TD-LAB V34M Country of origin : Italy Machine type: Auto lab dispanse No. of container: 181 Maximum capacity per container: 900 ml Year: 2010

- 132. Industrial Attachment Page 127 of 229 Sample dyeing machine Machine No.: KDSD - 01 Brand name: COPOWER Serial no.: R1728-1SCN124 Model: Supermat Country of origin : Taiwan Machine type: Sample dyeing machine No. of cylinder: 24 RPM: 50 U: 220 V @ 50 Hz Machine No.: KDSD - 02 Brand name: COPOWER Serial no.: R1733-1SCN124 Model: Supermat Country of origin : Taiwan Machine type: Sample dyeing machine No. of cylinder: 24 RPM: 50 U: 220 V @ 50 Hz

- 133. Industrial Attachment Page 128 of 229 Machine No.: KDSD - 03 Brand name: COPOWER Serial no.: R2252-1SCN124 Model: Supermat Country of origin : Taiwan Machine type: Sample dyeing machine No. of cylinder: 24 RPM: 50 U: 220 V @ 50 Hz Machine No.: KDSD - 04 Brand name: COPOWER Serial no.: R2274-1SCN124 Model: Supermat Country of origin : Taiwan Machine type: Sample dyeing machine No. of cylinder: 24 RPM: 50 U: 220 V @ 50 Hz Machine No.: KDSD - 05 Brand name: COPOWER Serial no.: R1904-1SCN124

- 134. Industrial Attachment Page 129 of 229 Model: Supermat Country of origin : Taiwan Machine type: Sample dyeing machine No. of cylinder: 24 RPM: 50 U: 220 V @ 50 Hz Machine No.: KDSD - 06 Brand name: COPOWER Serial no.: R1905-1SCN124 Model: Supermat Country of origin : Taiwan Machine type: Sample dyeing machine No. of cylinder: 24 RPM: 50 U: 220 V @ 50 Hz Machine No.: KDSD - 07 Brand name: Data Color Country of origin : USA Machine type: Sample dyeing machine No. of cylinder: 14 RPM: 50

- 135. Industrial Attachment Page 130 of 229 U: 220 V @ 50 Hz Programe used Programe #1: ISO Programe #2: Migration Programe #3: 80 °C x 60 min. (HOT) Programe #4: 98 °C x 45 min. (WHITE) Programe #5: 135 °C x 45 min. (DISPERSE) Programe #6: (60-130) °C x 45 min. (DISPERSE LYCRA) Programe #7: 80 °C x 40 min. (REDUCTION CLEARING) Lab hydroextractor Machine No.: KLE - 02 Brand name: SDL Country of origin : UK Machine type: Lab extractor U: 250 V @ 50 Hz Oven and incubator Machine No.: KOI - 02 Brand name: J. H. Heal Country of origin : UK Machine type: Oven and incubator

- 136. Industrial Attachment Page 131 of 229 Recipe for reduction clearing Dark shade: >2% Na2S2O4 – 6 g/l NaOH – 2 g/l OS – 2 g/l Time x Temperature - 80 °C x 40 min. Medium/Light shade: Na2S2O4 – 4 g/l NaOH – 2 g/l OS – 2 g/l Time x Temperature - 80 °C x 40 min. Sampling Actual Calculate d 4.5 g 5 g 9 g 10 g

- 137. Industrial Attachment Page 132 of 229 Salt and soda recommendation Drimarin % of dyestuff 0.01-0.5 0.5-1 1-2 2-3 3-5 5 & above Gluber salt (g/l) 20 40 50 60 70 80 Soda (g/l) 1 1.5 2 2.5 3 4 Synozol % of dyestuff 0.01-0.1 0.1-0.5 0.5-1 1-3 3 & above Gluber salt (g/l) 20 30 40 50 60 Soda (g/l) 10 15 15 20 20 Amtex % of dyestuff 0.01-0.5 0.5-1 1-2 2-4 Red/Navy 4 & above Black 5 & above Gluber salt (g/l) 30 50 60 70 80 80 Soda (g/l) 10 15 20 20 15 15 Custic (g/l) 1 1

- 138. Industrial Attachment Page 133 of 229 Remazol % of dyestuff ≤ 0.1 0.1-0.5 0.5-1 1-2 2-3 3-5 5 & above Gluber salt (g/l) 20 25 30 40 50 60 80 Soda (g/l) 5 8 10 12 15 20 20 Novacron % of dyestuff 0.01- 0.1 0.1- 0.25 0.25- 0.5 0.5-1 1-2 2-3 3-4 4-5 5 & above Gluber salt (g/l) 10 15 20 30 40 50 60 70 80 Soda (g/l) 8 10 12 14 16 18 20 20 5 Custic (g/l) 1 WET LAB Washing machine Machine No.: KDWS - 01 Brand name: Electrolux Model: W455H Machine type: Washing machine Country of origin : Sweden

- 139. Industrial Attachment Page 134 of 229 Machine No.: KDWS - 02 Brand name: Electrolux Model: W455H Machine type: Washing machine Country of origin : Sweden Machine No.: KDWS - 03 Brand name: Electrolux Washcator Machine type: Washing machine Country of origin : Sweden Machine No.: KDWS - 04 Brand name: Electrolux Machine type: Washing machine Country of origin : Sweden Machine No.: KDWS - 05 Brand name: Electrolux Model: F0M71 CLS Machine type: Washing machine Country of origin : Sweden

- 140. Industrial Attachment Page 135 of 229 Machine No.: KDWS - 06 Brand name: Meiling Ston Model: XQG50-998 Machine type: Washing machine Country of origin : China Machine No.: KDWS - 07 Brand name: Meiling Ston Model: XQG50-998 Machine type: Washing machine Country of origin : China Rota washing machine Machine No.: KDRW - 01 Brand name: SDL Machine type: Rota washing machine Country of origin : UK Machine No.: KDRW - 02 Brand name: FONG’S Serial no.: 97-11-288 Machine type: Rota washing machine Country of origin : China U: 415 volt @ 50 Hz

- 141. Industrial Attachment Page 136 of 229 Tumble dryer Machine No.: KDTD - 01 Brand name: Electrolux Serial no.: 60130/0002728 Model: T4130 Machine type: Tumble dryer Country of origin : Sweden U: 220 volt @ 50 Hz Machine No.: KDTD - 02 Brand name: Ariston Model: Electrolux/3 Machine type: Tumble dryer Country of origin : USA Machine No.: KDTD - 04 Brand name: SDL Machine type: Tumble dryer Country of origin : UK Machine No.: KDTD - 05 Brand name: SDL Machine type: Tumble dryer Country of origin : UK

- 142. Industrial Attachment Page 137 of 229 Sample cutter Machine No.: KDQP - 01 Brand name: Roches Model: Ouick Punch Machine type: Sample cutter Country of origin : UK Quick wash Machine No.: KDQP - 01 Brand name: Raitech Model: Ouick Wash Plus Machine type: Quick washing machine Country of origin : USA PHYSICAL TESTING LAB Oven and incubator Machine No.: KOI - 01 Brand name: J. H. Heal Country of origin : UK Machine type: Oven and incubator Machine No.: KOI - 04 Brand name: J. H. Heal Country of origin : UK

- 143. Industrial Attachment Page 138 of 229 Machine type: Oven and incubator Pilling tester Machine No.: KIPT - 01 Brand name: J. H. Heal Model: Orbitor Country of origin : UK Machine type: Pilling tester Machine No.: KIPT - 02 Brand name: SDL Country of origin : UK Machine type: Pilling tester Pilling assesment viewer Brand name: Veri Vide Twist tester Machine No.: KTT - 02 Brand name: SDL Country of origin : UK Machine type: Electronic twist tester Principle used: untwist- twist method

- 144. Industrial Attachment Page 139 of 229 Wrap reel Machine No.: KYCM - 01 Brand name: SDL Country of origin : UK Machine type: Wrap reel Sublimation tester Machine No.: KLST - 01 Brand name: SDL Country of origin : UK Machine type: Sublimation tester Bursting tester Machine No.: KBT - 01 Brand name: J. H. Heal Model: TruBurst2 Country of origin : UK Machine type: Bursting tester Rubbing tester Machine No.: KCM - 01 Brand name: J. H. Heal Model: Crock Master Country of origin : UK

- 145. Industrial Attachment Page 140 of 229 Machine type: Rubbing tester Yarn examiner Machine No.: KYE - 01 Brand name: SDL Country of origin : UK Machine type: Yarn examiner Light and weather fastness tester Machine No.: KYE - 01 Brand name: J. H. Heal Model: Apollo Country of origin : UK Machine type: Light and weather fastness tester

- 146. Industrial Attachment Page 141 of 229 Permisible testing limit of varfious tests demanded by buyers Test H & M Jules Okaidi We K & L Philder Shrinkage L-5% L-5% L-5% L-5% L-5% L-6% W-5% W-5% W-5% W-5% W-5% W-4% Twisting 5% 3% 2%(Solid) 3% 5% 2% 1%(Y/D) CF(wash) S- (3-4) S- 4 S- 4 S- (3-4) S- (3-4) S- >4 C- 4 C- 4 C- (4-5) C- (4-5) C- 4 C- >4 Rubbing Dry- (3-4) Dry- 4 Dry- 4 Dry- 4 Dry- 4 Dry- >(3- 4) Wet- (3-4) Wet- 4 Wet- (2-3) Wet- (2-3) Wet->(3-4) Perspiration S- (3-4) N/A S- 4 S- (3-4) S- (3-4) S- >4 C- 4 C- 4 C- (3-4) C- (3-4) C- >4 Saliva C- 4 N/A C- 5 N/A N/A C- >4 S- 4 S- N/A N/A Light C- 4 C- 4 C- 4 C- 4 Dk- (4-5); Lt- 4 C- >4 Pilling 3(14400) 3(14400) 3-4(14400) 3(10800) 4(10800) >3(10800) Formalodehyde ISO-14184-1 JIS-1041.1983, Option-A

- 147. Industrial Attachment Page 142 of 229 ISO-14184-1 1 gm sample + 100 ml distilled water 40° x 60' in water bath Cooling 1 hr. at room temperature Filtering by filter paper 5 ml liquid + 5ml Nash reagent 40° x 30' in water bath Cooling 30 min. at room temperature Measurement

- 148. Industrial Attachment Page 143 of 229 JIS-L-1041.1983, Option-A 2.5 gm sample + 100 ml distilled water 40° x 60' in water bath Cooling 1 hr. at room temperature Filtering by filter paper 5 ml liquid + 5ml Nash reagent 40° x 30' in water bath Cooling 30 min. at room temperature Measurement

- 149. Industrial Attachment Page 144 of 229 Nash Reagent Acetic acid – 1.5 ml Acetyl acetone – 1 ml Ammonium acetate – 75 gm Distilled water – 500 ml

- 150. Industrial Attachment Page 145 of 229 CHAPTER – 4 RAW MATERIALS

- 151. Industrial Attachment Page 146 of 229

- 152. Industrial Attachment Page 147 of 229 Raw material is a unique substance in any production oriented textile industry. It plays a vital role in continuous production & for high quality fabric. Types of Raw Materials The basic raw materials used are Yarns Dyes Chemicals & auxiliaries Fabric Name & Sources of raw materials Yarn C.V.C P.C 100% cotton Gery méllange Viscose Lyocell Modal 100% polyester etc. Yarn source Padma Textiles Badsha Textiles Thermax Group & others Grey Fabric Single jersey Lycra Single jersey Single lacoaste Double lacoaste

- 153. Industrial Attachment Page 148 of 229 Polo pique Slub jersey Heavy jersey 1x1 rib 2x2 rib 2x1 rib 1x1 lycra rib 2x2 laycra rib Pointal rib V-rib Flat bed rib French terry One side fleece Both side fleece 1x1 interlock 2x2 interlock Fabric Sources : Knit Concern Ltd. Knitexcel Noor Textile Mother Knitting Microfibre Ibrahim Knitex

- 154. Industrial Attachment Page 149 of 229 CHEMICALS LIST Name of agent No. Name of item Name of company Antifoam 1. Kappasol AF-2000 Kapp Chemi GMBH 2. Albaflow FFC Huntsman Singapore Anticreasing 3. Albafluid C 4. Kappavon AC 65 Kapp Chemie GMBH 5. Kappavon CL 6. Kappavon FCB 7. Hexapon NEH Hancle 8. Fincrease K5 Marlateks Teknoloji Detergent 9. Kappawet BOSS Kapp Chemie GMBH 10. Kappawet SOB 11. Fistol ET-OLS Marlatex Teknoloji 12. Fabrevol KNN Conc Denimist 13. Ultravon EL Hantsman Singapore Oil remover 14. Muscour OSRn Matex International Sequestering 15. Denquest HYN Denge KimyaTesktil Stabilizer 16. Denstab ESG Enzyme 17. Unizyme 1000L Shangha i Youtell Peroxide killer 18. Antiper R Levelling 19. Albatex-DBC Huntsman Singapore 20. Denwet TYDY Denge KimyaTesktil Soaping agent 21. Kappacom E 12 Kapp Chemie GMBH 22. Exaclean BLC Denimist

- 155. Industrial Attachment Page 150 of 229 Fixing 23. Albafix ECO Huntsman Singapore 24. Albafix FRD Cat- ionic softner 25. Softner SA 1000 Taiwan surfactant 26. Kappasoft BD Kapp Chemie GMBH 27. Softner GWS Mollah Enterprise 28. Mesoft CCS Matex International Non-ionic softner 29. Softner E 31 Taiwan surfactant 30. Kappasoft N 69 Kapp Chemie GMBH 31. Sapamine FPG Huntsman Singapore 32. Densoft-N (liq.) Denge KimyaTesktil Silicon softner 33. Kappasoft SM Kapp Chemie GMBH 34. Wisifect MIC H Denimist Core Nutralizer 35. Invatex AC Huntsman Singapore Fixing remover 36. Invalon DAM Special chemical 37. Lyoprint RG GRAN 38. Denkom SYT Denge KimyaTesktil 39. Alpclean (Viscose) 40. Albatex co Huntsman Singapore 41. Defaten FX(Hit set) Denge KimyaTesktil 42. Cyclanon XC W NEW BASF 43. Hayclean(M/c wash) Denge KimyaTesktil Basic Chemicals 44. Glaber salt Tradeasia Internationa l 45. Castic soda Gojrat

- 156. Industrial Attachment Page 151 of 229 46. Soda ash Human Chembird Indust. 47. Hydrose BASF 48. Oxalic Acid Mollah Enterprise 49. Formic Acid BASF 50. Kappatex R98 Kapp Chemie GMBH 51. Acetic Acid OCI Corporation Disperse Chemical 52. Albatex AB45 Huntsman Singapore 53. Albatex AR 54. Eriopon OLS 55. ErioponOS 56. Ultraphil HSD 57. Univadine DIF 58. Univadine DP Extra Chemical 59. Orgasoft CP Organic Kimya 60. Prepart VA NEW BASF 61. Vivatex HKN Huntsman Singapore 62. Decoloring Agent 63. Pragama FLOC-C Panta Rai 64. Jintex WD Conc Jintex Corporation 65. Jintex WRN 66. Dymacle DMB 101 Polyester Chemical 67. Stabilon CT Huntsman Singapore 68. Stabilon NY

- 157. Industrial Attachment Page 152 of 229 69. Ultraphil PA 70. Univadin PA 71. Eripon LT DYES LIST NO. Name of item Name of company Remarks 1. Avitera Deep Blue SE 2. Avitera Red SE 3. Avitera Yellow SE 4. Novacron Deep Cherry S-D 5. Novacron Blue FNR 6. Novacron Brili Yellow H4GN 7. Novacron Briliant Blue FNG 8. Novacron Dark Blue- WR 9. Novacron Red FN-2BL 10. Novacron Brown NC 11. Novacron Red FNR 12. Novacron Yellow-S3R 13. Novacron Yellow F4G 14. Novacron Brilliant Red FN3GL 15. Novacron Deep Neight SR 16. Novacron Yellow-FN2R 17. Novacron Brilliant Blue-HGR

- 158. Industrial Attachment Page 153 of 229 18. Novacron Super Black G HUNTSMAN Reactive dyes 19. Novacron Turquish GN 20. Novacron Navy FNB 21. Novacron Ocean SR 22. Terasil Black WNS Disperse dyes 23. Terasil Red WWFS 24. Terasil Blue WBLS 25. Terasil G yellow 3R 26. Terasil Navy WSR 27. Terasil Red WSR 28. Terasil yellow W6GS 29. Uvitex BAM OBA 30. Uvitex BHT 31. Uvitex CIDN 32. Bezactive Red-S3B-300% Bezama AG 33. Bezactive Blue-SMAX 34. Bezactive Red-SLF 35. Dychufix Yellow-3R-XF 150% Dysin Chem 36. Dychufix Yellow-4GL 37. Dychufix Yellow-EC 38. Synozol Navy blue HB 39. Synozol Red HB 40. Synozol Deep Red HB

- 159. Industrial Attachment Page 154 of 229 41. Synozol Yellow HB Kyung-ln Synthetic Corporation Reactive dyes 42. Synozol Blue K-BR 43. Synozol Turquish Blue HF-G 266% 44. Synozol Brilliant Blue RSPL 150% 45. Synozol Ultra Black G 46. Synozol Red K-3BS 47. Synozol Red HF-3B 48. Synozol Yellow KHL 49. Synozol Red KHL 50. Synozol Blue KHL 51. Synozol Yellow HF-4GL 52. Synozol Yellow HF-3GN 53. Synozol Yellow K-3RS 54. Amron Navy HR-2D 55. Amron Yellow HR-2D 56. Amron Yellow HF2GL 57. Amron Brilliant Red HF2R 58. Amron Red HF2F 59. Amron Red HR2D 60. Amron Blue RSPL 61. Amron Orange HFGR 62. Amron Yellow HFGR

- 160. Industrial Attachment Page 155 of 229 63. Amron Blue HFBR Amtex Dyechem Reactive dyes 64. Amron Red HF4BL 65. Amron Blue RC 66. Amron Blue HR2D 67. Amron Ultra Red HR4D 68. Amtex Yellow 3R-XF 69. Amtex Red 3B-XF 70. Drimarine Violet K-2RL Clariant 71. Drimarine Yellow K-2R 72. Reactive Yellow 3R OH Young Industrial Co. 73. Sunfix Blue HBR 74. Sunfix Red MF-3BD 75. Reactive Black VG Virag Int. 76. Remazol Blue RR Dystar 77. Remazol Red RR 78. Remazol Yellow RR 79. Remazol Navy RGB 80. Remazol Ultra Carmine RGB 81. Remazol Brilliant Yellow 3GL 82. Remazol Ultra Red RGB 83. Remazol Ultra Yellow RGB Hangzhou Jihua 84. Reactive Starfix Black B 150% 85. Reactive Starfix Navy RGN