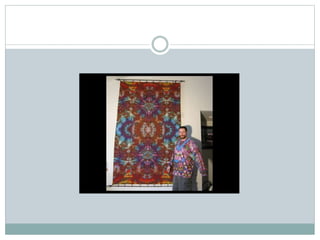

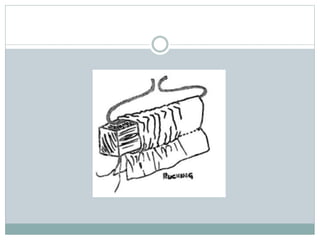

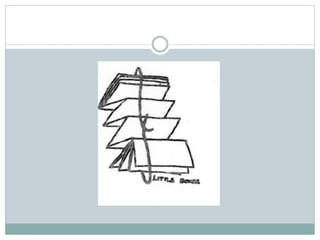

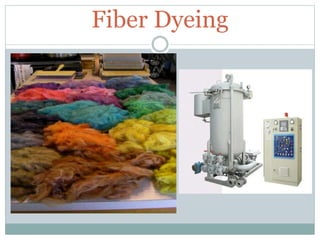

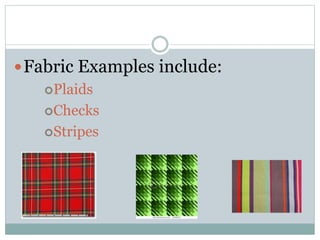

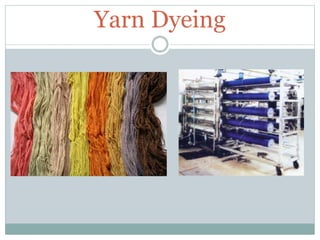

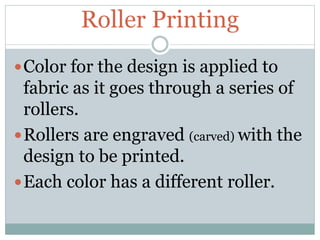

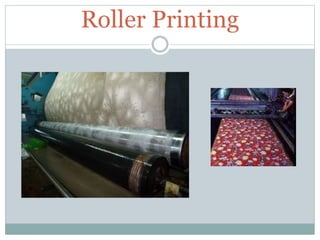

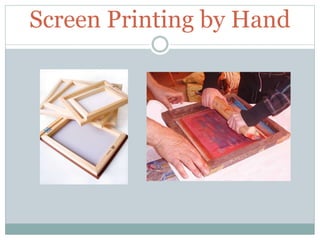

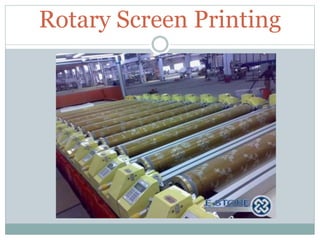

The document discusses fabric dyeing, printing, and finishing techniques, emphasizing the importance of dye selection and various methods such as fiber, yarn, and piece dyeing. It outlines printing techniques like roller, screen, rotary screen, heat transfer, and digital printing, each with distinct advantages and applications. The document highlights the processes and materials involved in achieving desired color effects on textiles.