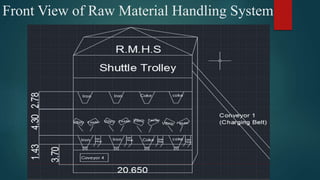

The document presents a project on the design and development of a de-dusting system aimed at minimizing dust emissions from a raw material handling system used in a blast furnace plant. It details the literature review, problem identification regarding significant dust emissions, and the proposed technical solutions, including the layout and calculations for system efficiency and required fan capacity. Future work involves implementing the design as accepted by the collaborating company, which is working on finding a fabricator for the system.

![Calculations.

The motor HP required is obtained from the manual of the supplier

[Rajdeep Engineering] is 40HP motor.](https://image.slidesharecdn.com/finalreview14bme160-170616050544/85/De-Dusting-System-21-320.jpg)