Coal Dust Explosion and its Safety at Thermal Power Plant

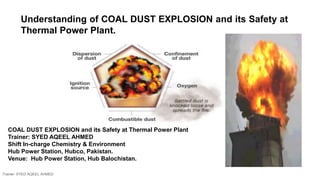

- 1. Understanding of COAL DUST EXPLOSION and its Safety at Thermal Power Plant. COAL DUST EXPLOSION and its Safety at Thermal Power Plant Trainer: SYED AQEEL AHMED Shift In-charge Chemistry & Environment Hub Power Station, Hubco, Pakistan. Venue: Hub Power Station, Hub Balochistan. Trainer: SYED AQEEL AHMED

- 2. Goal To improve the safety of workers in environments where combustible dusts may be encountered by increasing employee awareness of this hazard and by demonstrating how the hazard can be recognized and addressed in their workplace. Trainer: SYED AQEEL AHMED

- 3. Enabling Learning Objectives Identify the elements necessary for dust to explode. Explain how to prevent dust from reaching combustible levels. Describe the difference between primary and secondary dust explosions. Trainer: SYED AQEEL AHMED

- 4. Terminal Learning Objective Program participants will understand: Combustible dust danger in their industry. The Dust, Fire, and Explosive Pentagon. The methods to prevent or mitigate the effects of combustible dust explosion and resulting fire. Trainer: SYED AQEEL AHMED

- 5. Are These Materials Explosive? sugar metal plastic wood coal medicines Trainer: SYED AQEEL AHMED

- 6. Trainer: SYED AQEEL AHMED

- 7. Introduction The first documented dust explosion occurred in a Turin, Italy, bakery in 1785. The explosion was caused by the ignition of flour dust by a lamp in a bakery storeroom. It lead to the realization that grain dust is a highly explosive substance that must be handled carefully. Trainer: SYED AQEEL AHMED

- 8. Imperial Sugar Company, Port Wentworth GA. Explosion and Fire Feb. 7, 2008 13 Dead and Numerous serious injuries Trainer: SYED AQEEL AHMED

- 9. Trainer: SYED AQEEL AHMED

- 10. Dust Explosions The additional dust dispersed into the air may cause one or more secondary explosions. These can be far more destructive than a primary explosion An initial (primary) explosion in processing equipment or in an area where fugitive dust has accumulated may shake loose more accumulated dust, Or damage a containment system (such as a duct, vessel, or collector). Trainer: SYED AQEEL AHMED

- 11. Dust Combustibility Combustible dust per NFPA 654 Prior to 2006 - “Any finely divided solid material that is 420 microns or smaller in diameter (material passing a U.S. No. 40 Standard Sieve) and presents a fire or explosion hazard when dispersed and ignited in air.” 2006 Edition – A combustible particulate solid that presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations, regardless of particle size or shape.Trainer: SYED AQEEL AHMED

- 12. Deflagration Vs. Explosion Deflagration. Propagation of a combustion zone at a speed that is less than the speed of sound in the unreacted medium. Detonation. Propagation of a combustion zone at a velocity that is greater than the speed of sound in the unreacted medium. Explosion. The bursting or rupture of an enclosure or a container due to the development of internal pressure from deflagration. Explosion Deflagration Detonation Definitions and Terminology Trainer: SYED AQEEL AHMED

- 13. The lower flammable limit is the lowest concentration of a combustible substance in an oxidizing medium How are MEC and LFL Different? Minimum Explosible Concentration (MEC)The minimum concentration of combustible dust suspended in air, measured in mass per unit volume that will support a deflagration. Lower Flammable Limit (LFL) Upper Flammable Limit (UFL) The upper flammable limits is the highest concentration of a combustible substance in an oxidizing medium that will propagate a flame. Definitions and Terminology Trainer: SYED AQEEL AHMED

- 14. Definitions and Terminology Minimum Ignition Temperature (MIT). The lowest temperature at which ignition occurs. Lower the particle size – Lower the MIT Lower the moisture content - Lower the MIT Minimum Ignition Energy (MIE). The lowest electrostatic spark energy that is capable of igniting a dust cloud. Energy Units (millijoules) Decrease in particle size and moisture content – decreases MIE An increase in temperature in dust cloud atmosphere - decreases MIE Deflagration Index, Kst – Maximum dp/dt normalized to 1.0 m3 volume. Pmax – The maximum pressure reached during the course of a deflagration. Trainer: SYED AQEEL AHMED

- 15. Dust explosion class Kst (bar.m/s) Characteristic St 0 0 No explosion St 1 >0 and <=200 Weak explosion St 2 >200 and <=300 Strong explosion St 3 >300 Very strong explosion Deflagration Index - Kst Kst = (dP/dt)max V1/3 (bar m/s) where: (dP/dt) max = the maximum rate of pressure rise (bar/s) V = the volume of the testing chamber (m3) Trainer: SYED AQEEL AHMED

- 16. The minimum amount of dust suspended in air that will support deflagration. It is estiamted that this concentration (MEC) can reduce the visibility of a 25 wat bulb in a room to only 6 feet of distance Minimum Explosive Concentration (MEC) 25 watts 6 feet = 2 meters Combustible dust concentration suspended in air > MEC Source: Course 7120 OSHA Training CenterTrainer: SYED AQEEL AHMED

- 17. What is wrong here? Trainer: SYED AQEEL AHMED

- 18. Fire Prevention and Control Policies, practices and procedures designed to keep the conditions necessary for a fire from coming together (explosive pentagon) Fuel (dust) Dust is dry Dust is at MEC Oxygen Ignition source Confined or enclosed space Mixing of fuel and oxygen Explosive Pentagon Fuel Dispersion Oxygen Confinement Ignition Trainer: SYED AQEEL AHMED

- 19. Explosion Results from the combination of these factors: • fire • dispersion of solid particulate material • in a more or less enclosed space + + =fire dispersion Explosion confinement Trainer: SYED AQEEL AHMED

- 20. Combustion Principles Fire is a rapid oxidation process with the evolution of light and heat in varying intensities. 2C + O2 2CO Deflagration is a combustion reaction in which the velocity of the reaction front through the unreacted fuel medium is less than the speed of sound. Trainer: SYED AQEEL AHMED

- 21. Explosion Severity Index (US Bureau of Mines) Relative explosion hazard rating Ignitio n sensitiv ity Explosi on Severit y Index of explosibilit y Weak <0.2 <0.5 <0.1 Moderate 0.2 – 1.0 0.5 – 1.0 0.1 – 1.0 Strong 1.0 – 5.0 1.0 – 2.0 1.0 - 10 Severe >5.0 >2.0 >10 Trainer: SYED AQEEL AHMED

- 22. Ignition Sensitivity Minimum Ignition Temperature X Minimum Ignition Energy X Minimum Explosible Concentration) Pittsburgh Coal dust Minimum Ignition Temperature X Minimum Ignition Energy X Minimum Explosible Concentration) Sample dust Trainer: SYED AQEEL AHMED

- 23. Explosion Severity (Maximum Explosion Pressure X Maximum Rate of Pressure Rise) Sample dust (Maximum Explosion Pressure X Maximum Rate of Pressure Rise) Pittsburgh Coal dust Trainer: SYED AQEEL AHMED

- 24. Index of Explosibility Ignition Sensitivity X Explosion Severity Trainer: SYED AQEEL AHMED

- 25. A timeline The following nine slides depict a timeline for a dust explosion and the results of that explosion. Trainer: SYED AQEEL AHMED

- 26. Time, msec. (Timing of actual events may vary) 0 25 50 75 100 125 150 175 200 225 250 300 325 Primary deflagration inside process equipment Trainer: SYED AQEEL AHMED

- 27. Shock wave caused by primary deflagration Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Trainer: SYED AQEEL AHMED

- 28. Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Shock waves reflected by surfaces within the building cause accumulated dust to go into suspension Trainer: SYED AQEEL AHMED

- 29. Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Dust clouds thrown in the air by the shock waves Trainer: SYED AQEEL AHMED

- 30. Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Primary deflagration breaks out of the equipment enclosure - creating a source of ignition Trainer: SYED AQEEL AHMED

- 31. Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Secondary deflagration ignited Trainer: SYED AQEEL AHMED

- 32. Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Secondary Deflagration is propagated through the dust clouds Trainer: SYED AQEEL AHMED

- 33. Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Secondary deflagration bursts from the building Trainer: SYED AQEEL AHMED

- 34. Time, msec. 0 25 50 75 100 125 150 175 200 225 250 300 325 Collapsed building with remaining fires Trainer: SYED AQEEL AHMED

- 35. Types of Dusts Involved in Explosions Trainer: SYED AQEEL AHMED

- 36. Required Conditions for an Explosion The dust must be combustible and fine enough to be airborne. The dust cloud must beat the Minimum Explosive Concentration (MEC) for that Particular dust. There must be sufficient oxygen in the atmosphere to support and sustain combustion. There must be a source of ignition. The dust must be confined. The dust must be dry. Dust Particle Trainer: SYED AQEEL AHMED

- 37. Ignition Sources Trainer: SYED AQEEL AHMED

- 38. Housekeeping NFPA 654 and FM Global Data Sheet 7-76 are referenced. Clean immediately whenever a dust layer of 1/32-inch thickness accumulates • over a surface area of at least 5% of the floor area of the facility or any given room. • not to exceed 1,000 ft 2 Sampling coal dust Trainer: SYED AQEEL AHMED

- 39. Housekeeping An idealized approach based on: Uniformity of the dust layer Bulk density of 75 lb/ ft 3 , Dust concentration of 0.35oz/ ft 3 , and Dust cloud height of 10 ft. 25 Ft 40 Ft 10 Ft 5% of 20,000 ft2 building Trainer: SYED AQEEL AHMED

- 40. Where Do Dust Explosions Occur? Dust explosions, for grain, usually occur at transfer points as in bucket elevators or enclosed conveyors. In 1997, 50 percent of primary explosions occurred in elevator legs. Accumulation of dust in suspended ceilings Cyclone collectors Electrostatic collectors Holding bins Trainer: SYED AQEEL AHMED

- 41. Explosion Safeguards Fire prevention and protection Housekeeping Dust control Trainer: SYED AQEEL AHMED

- 42. Fire Prevention and Control Hot work permits Lockout/tagout policies Design specifications for storage of flammable materials Severity reduction policies, practices and procedures designed to minimize the spread of fire Emergency plans Alarm systems Trainer: SYED AQEEL AHMED

- 43. Fire Prevention and Control Portable fire extinguishers Cleanup policies, practices and procedures designed to return the affected area to an operational level First aid Recharging portable extinguishers Removal of debris to an appropriate waste site Equipment and facility repair Trainer: SYED AQEEL AHMED

- 44. Housekeeping A crucial key to the reduction of fires and explosions is housekeeping. Housekeeping relates to hazards in addition to fires and explosions. Research has shown that facilities that are well maintained experience fewer fires, explosions and other accidents. Trainer: SYED AQEEL AHMED

- 45. Dust Control NFPA 654 – contains comprehensive guidance Some of its recommendations: Minimize the escape of dust from process equipment or ventilation systems;(fugitive dust). Use dust collection systems and filters. Utilize surfaces that minimize dust accumulation and facilitate cleaning. Spots are not raindrops Trainer: SYED AQEEL AHMED

- 46. ? NFPA 654 – guidance Provide access to all hidden areas to permit inspection. Inspect for dust residues in open and hidden areas, at regular intervals. Clean dust residues at regular intervals. Dust Control Trainer: SYED AQEEL AHMED

- 47. Dust Control NFPA 654 Use cleaning methods that do not generate dust clouds if ignition sources are present. Only use vacuum cleaners approved for dust collection. HAZ LOCTrainer: SYED AQEEL AHMED

- 48. Fugitive Dust Control and Housekeeping Dust Clouds Surfaces shall be cleaned in a manner that minimizes the generation of dust clouds. Vigorous sweeping or blowing down with steam or compressed air produces dust clouds and shall be permitted only if the following requirements are met: Trainer: SYED AQEEL AHMED

- 49. Area and equipment vacuumed prior to blow down. Electrical power and other sources of ignition shut down or removed from the area. Only low gauge pressure (15 psi) steam or compressed air to be used. No hot surfaces capable of igniting a dust cloud or layer. Fugitive Dust Control and Housekeeping Trainer: SYED AQEEL AHMED

- 50. Dust Control NFPA 654 Locate relief valves away from dust hazard areas and Develop and implement a hazardous dust Inspection, Testing, Housekeeping, and Written control program (Written with established frequency and methods). Trainer: SYED AQEEL AHMED

- 51. Dust Control Reducing dust accumulations is a major concern for facilities that produce dust. A good housekeeping program depends upon a combination of methods to control dust. The methods used in a given facility will depend upon the type of facility and the volume of organic material handled or produced. Trainer: SYED AQEEL AHMED

- 52. Dust Control Methods Vacuums especially in areas where dust accumulation is constant due to the job task being performed. Wash down procedures where hoses and water can be used to remove accumulated dust. Choke feeds to control the flow of grain and grain dust. Dust control systems such as filters or cyclones. Trainer: SYED AQEEL AHMED

- 53. Recognizing Dust Hazards All employees should be trained in hazard recognition: • Conduct general facility wide appraisals of dust explosion possibilities on a periodic basis. • Conduct internal and external audits in order to identify potential explosion hazards. • Encourage a preventative attitude among employees for dust explosions. • Have employees and supervisors identify explosion hazards through JHAs. • Pay particular attention to dust collection systems and other areas not in plain view during the assessment. Trainer: SYED AQEEL AHMED

- 54. U.S. Chemical Safety and Hazard Investigation Board Photo Trainer: SYED AQEEL AHMED

- 55. U.S. Chemical Safety and Hazard Investigation Board Photo Trainer: SYED AQEEL AHMED

- 56. Engineering Controls Avoid the use of compressed air (blow down), and dry sweeping. Conduct workforce training and education courses. Limit and control potential ignition sources. Ensure electrical service in combustible dustTrainer: SYED AQEEL AHMED

- 57. Engineering Controls Follow National Fire Protection Association (NFPA) standard 654. Ensure operations involving dusts have proper engineering design and controls. Maintain an effective housekeeping program. Establish and maintain a preventative maintenance program. Trainer: SYED AQEEL AHMED

- 58. Applicable OSHA Standards 1910.22 Housekeeping 1910.36 Design and Construction for Exit Routes 1910.37 Safeguards and Features for Exit Routes 1910.38 Emergency Action Plans 1910.39 Fire Prevention Plans 1910.94 Ventilation 1910.132 Personal Protective Equipment 1910.145 Specifications for Accident Prevention Signs and Tags 1910.146 Permit-Required Confined Space 1910.157 Fire Extinguishers 1910.165 Employee Alarm Systems 1910.176 Material handling 1910.178 Powered Industrial Trucks 1910.26 Electrical Power Generation 1910.272 Grain Handling Facilities 1910.307 Hazardous Locations 1910.1200 Hazard CommunicationTrainer: SYED AQEEL AHMED

- 59. General Duty Clause Must have a feasible means to abate the hazard in order for OSHA to cite the General Duty Clause Compliance Officers are allowed to use the NFPA standards as evidence of feasible means of abatement NFPA standards can also be used for evidence of industry recognition of the hazard Trainer: SYED AQEEL AHMED

- 60. NFPA Publications Relevant to Combustible Dust Hazard Controls NFPA Number Title Current Edition 61 Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities 2008 68 Guide for Venting of Deflagrations 2007 69 Standard on Explosion Prevention Systems 2008 70 National Electrical Code 2008 77 Recommended Practice on Static Electricity 2007 85 Boiler and Combustion Systems Hazards Code 2007 86 Standard for Ovens and Furnaces 2007 91 Standard for Exhaust Systems for Air Conveying of Vapors, Gases, Mists, and Noncombustible Particulate Solids 2004 484 Standard for Combustible Metals 2006 499 Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas 2008 654 Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids 2006 655 Standard for Prevention of Sulfur Fires and Explosions 2007 664 Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities 2007 Trainer: SYED AQEEL AHMED

- 61. Summary Dust explosions are a serious problem in American industry. During the past 25 years, at least 281 major combustible dust incidents were reported, that killed 119 and injured 718 workers, and destroyed many industrial facilities. Facilities fail to follow the widely recognized standards of good engineering practice in the NFPA’s voluntary consensus standards. Trainer: SYED AQEEL AHMED

- 62. Summary Facilities do not: • Implement appropriate engineering controls • Perform adequate maintenance • Implement good housekeeping practices • Follow other measures that could have prevented the explosions • Provide adequate hazard recognition training for employees • Establish overall safe work practices Trainer: SYED AQEEL AHMED

- 63. Thanks, any question please? Trainer: SYED AQEEL AHMED